Water-air alternate quenching heat treatment process for cast grinding ball production

A technology of casting grinding balls and air alternation, which is applied in heat treatment furnaces, heat treatment equipment, quenching agents, etc., can solve problems such as improper operation, easy to cause fire, complicated equipment, and unfavorable environment, so as to achieve good promotion and application value and avoid water quenching cracking , The effect of process safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] A kind of cast iron grinding ball, its element composition is as follows by weight percentage (by weight percentage, %):

[0022] element C Si mn Cr P S Fe CADI-120 3.64 2.42 2.23 0.34 0.025 0.018 margin

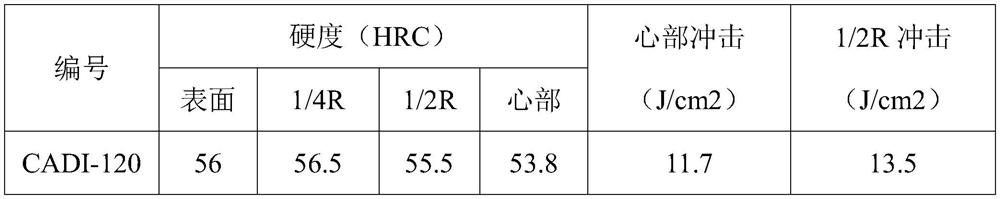

[0023] Heat treatment process: heat preservation at 900°C for 4 hours for austenitization, then use water-air alternate quenching heat treatment, water temperature is 26-29°C, primary quenching: quenching for 30s, outlet water temperature 420°C, secondary quenching: quenching for 20s, exiting water The temperature is 270°C, three times of quenching: quenching for 20s, the outlet water temperature is 190°C, and then isothermally treated at 220°C for 3h.

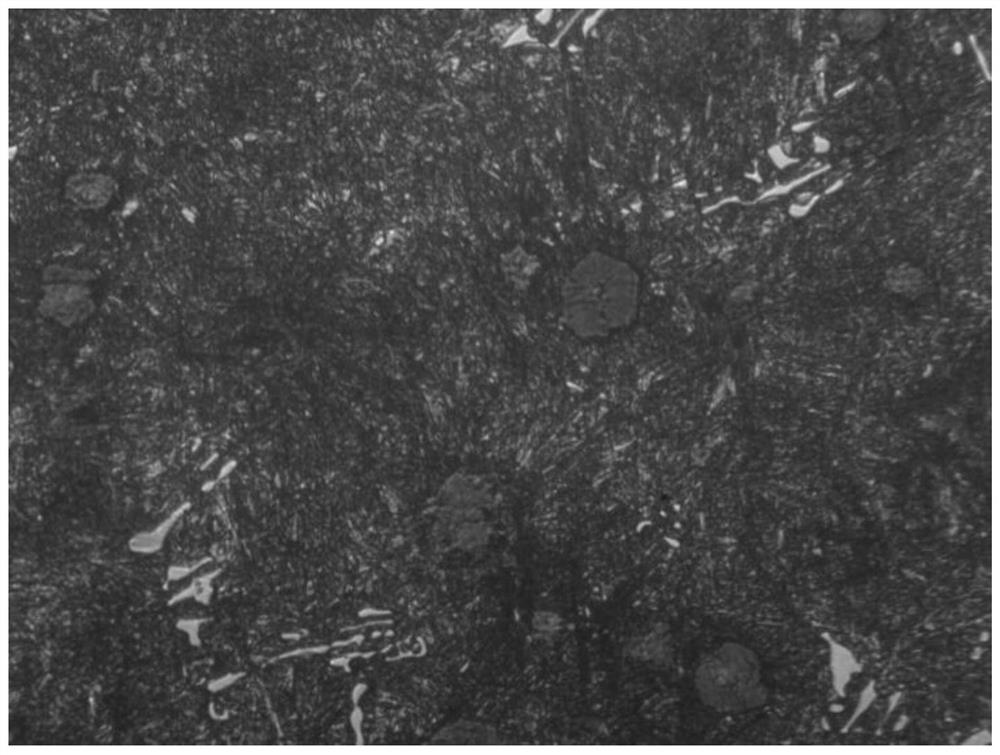

[0024] Characterize the metallographic structure of the cast iron grinding ball of embodiment 1, as figure 1 and figure 2 It can be seen from the figure that the surface and core of the ball are composed of acicular ferrite + retained austenite + carbide + spherical graphite, wh...

Embodiment 2

[0030] A kind of cast iron grinding ball, its element composition is as follows by weight percentage (by weight percentage, %):

[0031] element C Si mn Cr P S Fe CADI-100 3.54 2.52 2.23 0.38 0.025 0.018 margin

[0032] Heat treatment process: heat preservation at 890°C for 4 hours for austenitization, then adopt water-air alternate quenching heat treatment, water temperature is 26-29°C, primary quenching: quenching for 30s, water outlet temperature 380°C, secondary quenching: quenching for 10s, water outlet The temperature is 270°C, three times of quenching: quenching for 10s, the outlet water temperature is 220°C, and then isothermally treated at 220°C for 3h.

[0033] The mechanical performance of the cast iron grinding ball of embodiment 2 is detected, and the results are as follows:

[0034]

[0035] The MLD-10 of the cast iron grinding balls in Example 2 was used for comparative wear analysis, and the oil-quenched CADI-120 was use...

Embodiment 3

[0038] A kind of cast iron grinding ball, its element composition is as follows by weight percentage (by weight percentage, %):

[0039] element C Si mn Cr P S Fe CADI-150 3.54 2.45 2.06 0.34 0.025 0.018 margin

[0040] Heat treatment process: heat preservation at 900°C for 5 hours for austenitization, then adopt water-air alternate quenching heat treatment, water temperature is 26-29°C, primary quenching: quenching for 40s, water outlet temperature 480°C, secondary quenching: quenching for 20s, water outlet The temperature is 370°C, the third quenching: quenching for 20s, the outlet water temperature is 260°C, the fourth quenching: quenching for 15s, the outlet water temperature is 220°C, and then isothermally treated at 230°C for 4h.

[0041] The mechanical performance of the cast iron grinding ball of embodiment 3 is detected, and the results are as follows:

[0042]

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com