Water soluble environment protection hardening media

A quenching medium, water-soluble technology, applied in the direction of quenching agent, heat treatment equipment, manufacturing tools, etc., can solve the problems of insufficient hardness, uneven quenching, slow cooling speed, etc., achieve reasonable distribution of cooling characteristics, improve quenching hardness, adjustable big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

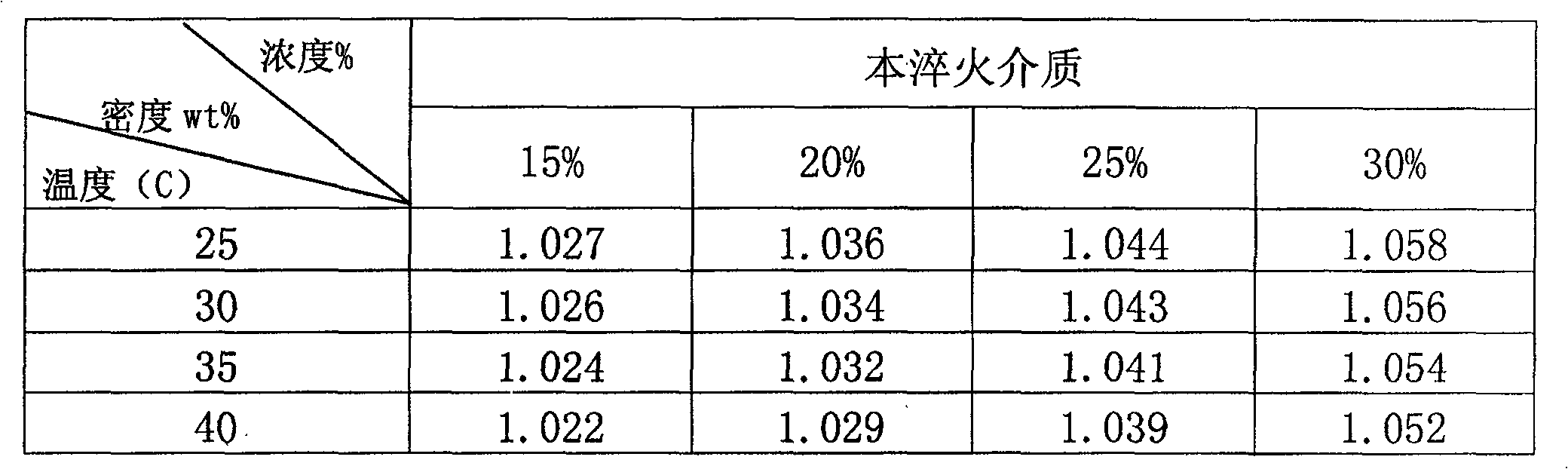

[0011] The stock solution of the water-soluble quenching medium of the present invention is prepared by mixing four components of cellulose, sodium chloride, potassium chloride and tap water with a molecular weight of 15000-30000, and the weight ratio of its components is as follows: cellulose 6% , 20% sodium chloride, 14% potassium chloride, and 60% water. The above-mentioned raw materials are measured by percentage and placed in a container for stirring until they are completely dissolved. The quenching medium made by the present invention has been proved by tests to be easily soluble in water, have no flash point, non-combustibility, non-toxic, odorless, and oil-free. It is a clean and environmentally friendly product, and the quenching area covers a wide range. The ideal quenching effect is achieved by means of the control of concentration and temperature.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com