Inorganic polymer water-soluble quenching medium and preparation method thereof

A technology of inorganic polymer and quenching medium, which is applied in the direction of quenching agent, manufacturing tools, heat treatment equipment, etc., can solve the problems of air pollution, narrow temperature range of medium use, large consumption of use, etc., to improve hardness and hardness uniformity, Reasonable distribution of cooling characteristics and the effect of reducing the transformation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

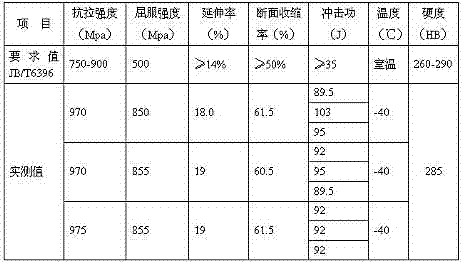

Examples

Embodiment 1

[0035] The preparation method of quenching medium is carried out according to the following steps successively:

[0036] a. 60 kilograms of polyaluminum chloride and 45 kilograms of water are placed in a container and stirred until completely dissolved, polyaluminum chloride, the molecular formula is [Al 2 (OH) n Cl 6-n ] m , m≤10, n=1~5;

[0037] b. Add 20 kilograms of aqueous sodium hydroxide solution with a concentration of 10% into the container and stir evenly;

[0038] c. Dissolve 15 kilograms of zinc chloride in 87 kilograms of water earlier, then place the zinc chloride aqueous solution in the container and stir evenly;

[0039] d. Dissolve 12 kilograms of Potassium Chloride in 87 kilograms of water earlier, then place Potassium Chloride aqueous solution in the container and stir evenly;

[0040] e. Prepare the solution in the container with water until the Baume degree is 8. That's it.

Embodiment 2

[0052] The preparation method of quenching medium is carried out according to the following steps successively:

[0053] a. 59 kilograms of polyaluminum chloride and 40 kilograms of water are placed in a container and stirred until fully dissolved;

[0054] b. Add 19 kilograms of aqueous sodium hydroxide solution with a concentration of 10% into the container and stir evenly;

[0055] c. Dissolve 14 kg of zinc chloride in 85 kg of water, then place the zinc chloride aqueous solution in the container and stir evenly;

[0056] d. Dissolve 11 kg of Potassium Chloride in 85 kg of water, then place Potassium Chloride aqueous solution in the container and stir evenly;

[0057] e. Prepare the solution in the container with water until the Baume degree is 20.

[0058] During use, the embodiment 2 of the present invention needs to be diluted with water to be 8-10 in Baume degree.

Embodiment 3

[0066] The preparation method of quenching medium is carried out according to the following steps successively:

[0067] a. 62 kilograms of polyaluminum chloride and 50 kilograms of water are placed in a container and stirred until fully dissolved;

[0068] b. 21 kilograms of concentration are 10% sodium hydroxide aqueous solution to add in the container and stir evenly;

[0069] c. Dissolve 16 kg of zinc chloride in 90 kg of water, then place the zinc chloride aqueous solution in the container and stir evenly;

[0070] d. be that the potassium chloride of 13 kilograms is dissolved in the water of 90 kilograms earlier by the mass fraction, then potassium chloride aqueous solution is placed in the container and stirs;

[0071] e. Prepare the solution in the container with water until the Baume degree is 35.

[0072] When in use, the embodiment 3 of the present invention needs to be diluted with water to be 8-10 in Baume degree.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com