Concrete sleeper curing cooling system and curing cooling method

A technology for concrete and sleepers, applied in auxiliary molding equipment, ceramic molding machines, manufacturing tools, etc., can solve the problems of poor control of the cooling process and high energy consumption, maximize energy utilization, reduce steam consumption, and reduce costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

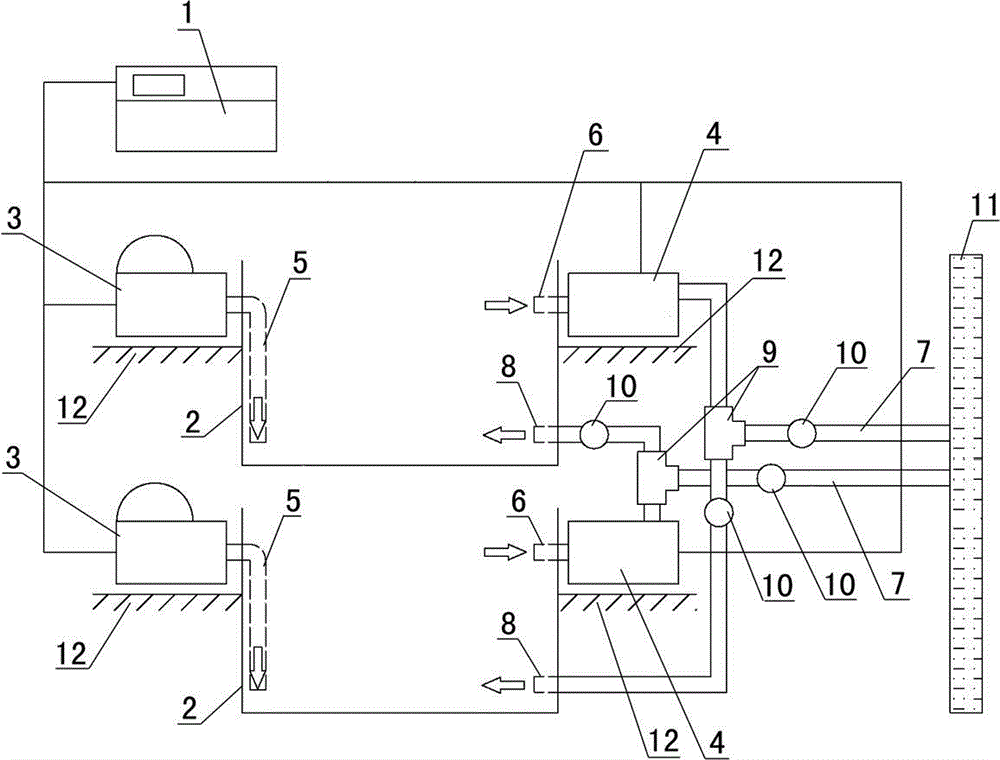

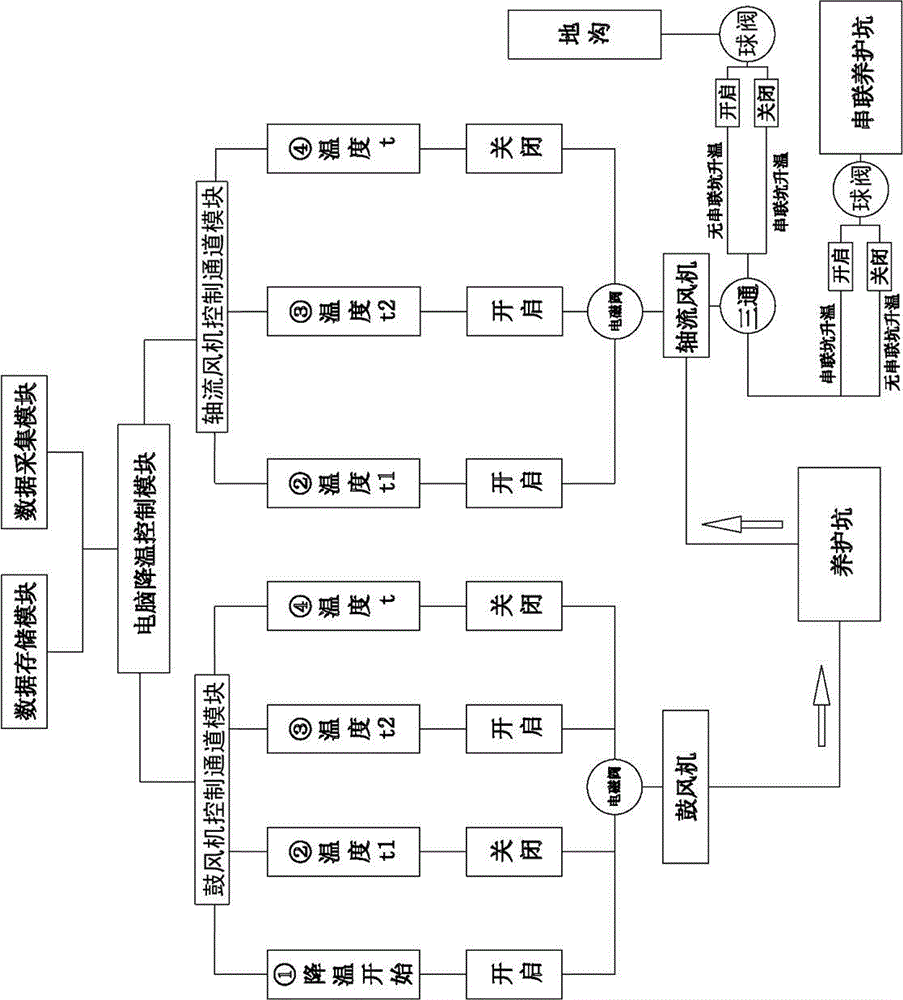

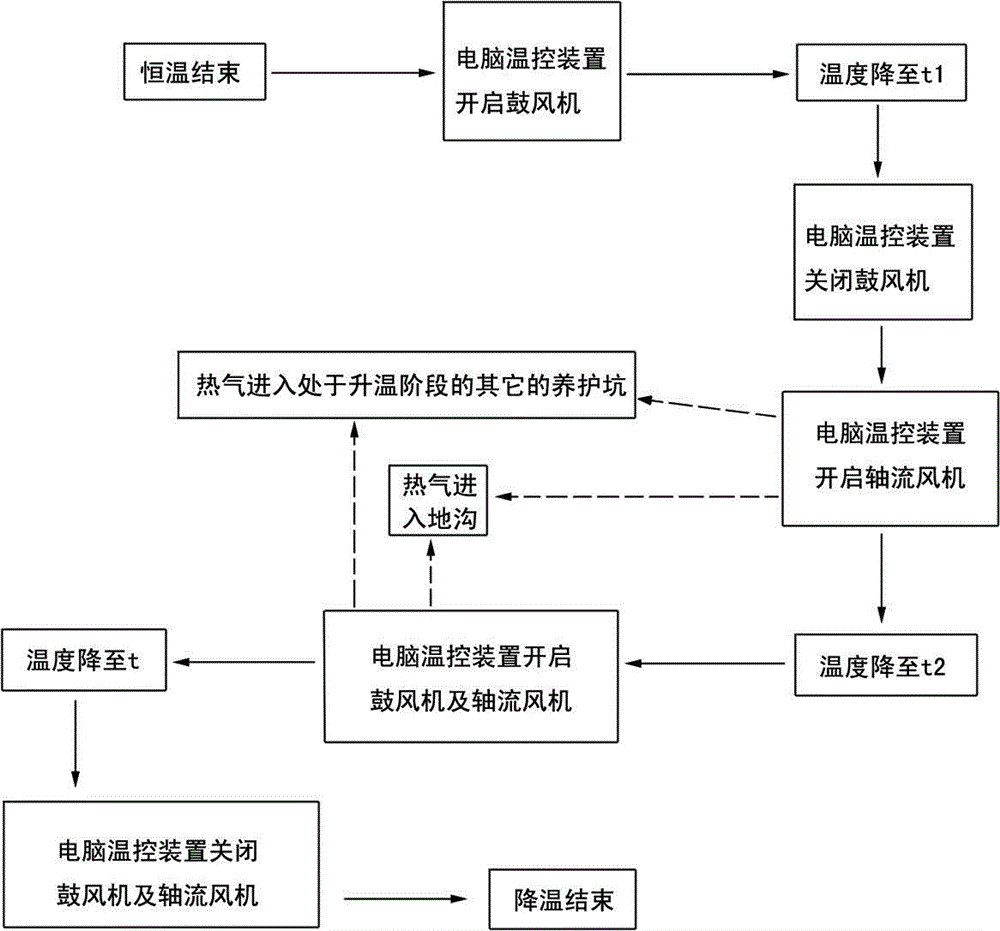

[0025] Examples see figure 1 , figure 2 As shown, this concrete sleeper maintenance and cooling system includes at least two curing pits 2. A blower 3 is provided on one side of the curing pit 2, and the air outlet of the blower communicates with the bottom of the curing pit 2 through an air inlet pipe 5.

[0026] The top of the pit on the other side of the maintenance pit 2 communicates with the inlet end of an air outlet pipe 6, the air outlet pipe 6 is provided with an axial flow fan 4, and the air outlet end of the air outlet pipe 6 is connected to a tee 9 The first interface is connected.

[0027] The second interface of the tee 9 communicates with the trench 11 through the exhaust pipe 7, and the third interface of the tee 9 communicates with other maintenance pits (also called series maintenance pits, referred to as series pits) through the return air pipe 8. The bottom of the pit is connected, and a ball valve 10 is provided on the exhaust pipe 7 and the air return ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com