Frozen bread dough containing composite antifreeze agent made from plant antifreeze proteins, preparation method of dough and method for preparing bread with optimized process

A technology of bread dough and antifreeze protein, applied in the field of food processing, can solve the problems of poor bread specific volume and sensory quality, poor stability of gluten network structure, low quantity of macromolecular protein, etc., to achieve large specific volume and excellent sensory quality , the effect of increasing the transmission rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

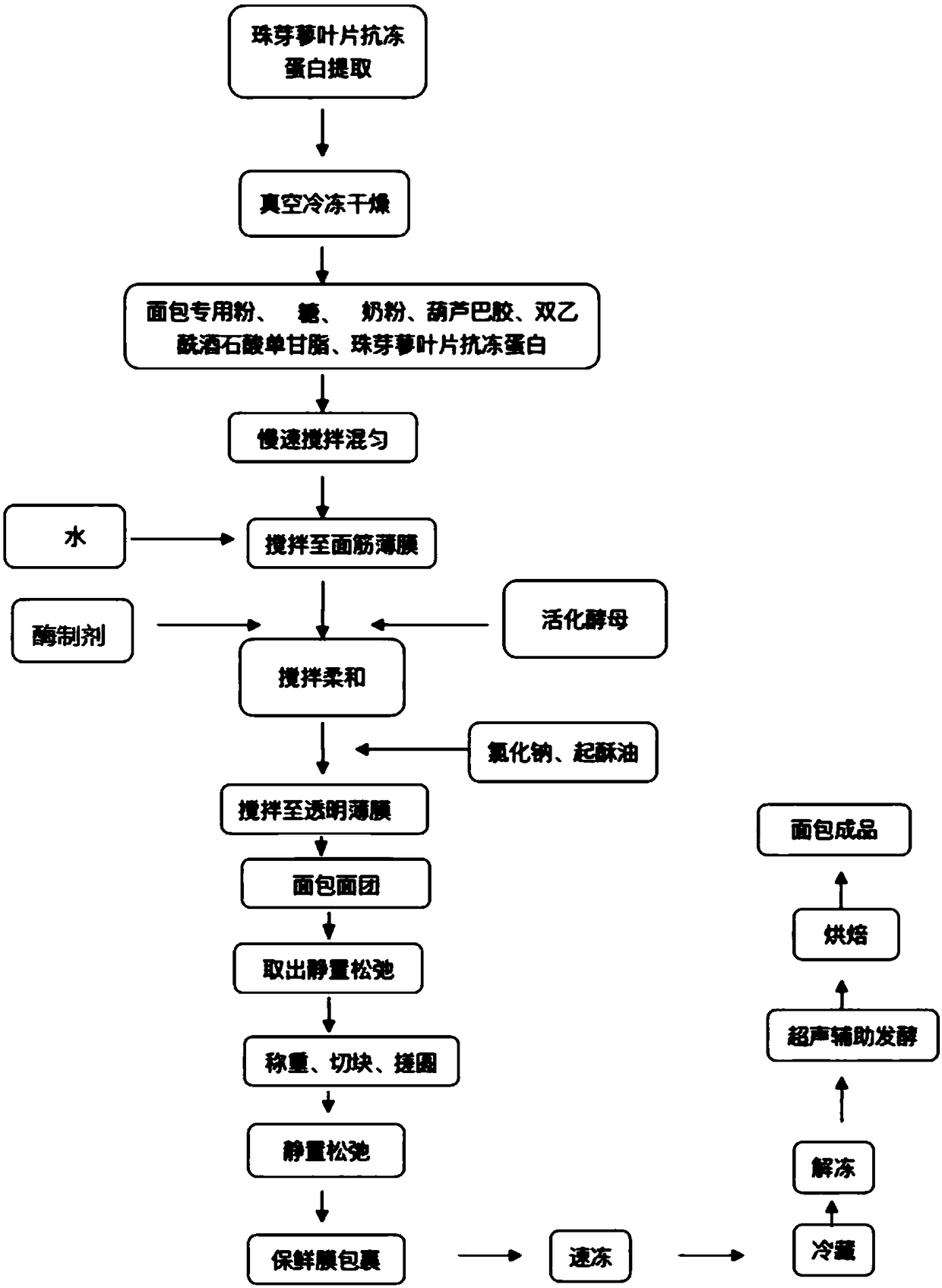

Method used

Image

Examples

Embodiment 1

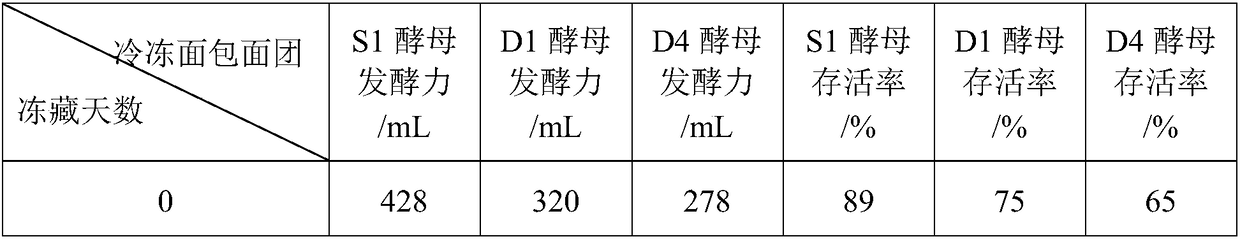

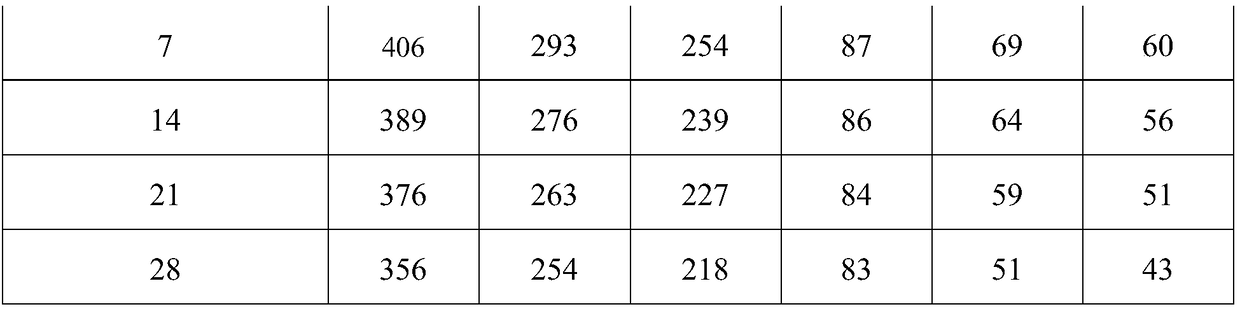

[0033] Prepare a kind of frozen bread dough containing plant antifreeze protein compound antifreeze agent, in terms of the total weight of this frozen bread dough, described frozen bread dough comprises the following components: bread flour 48wt%, sugar 11.58wt%, yeast 1.2 wt%, sodium chloride 0.4wt%, milk powder 1.64wt%, shortening 8.3wt%, fenugreek gum 0.15wt%, diacetate monoglyceride tartrate 0.19wt%, water 27.5wt%, glutamine transaminase 0.07wt% , 0.07wt% xylanase, 0.9wt% antifreeze protein powder of Polygonum versicolor leaves.

[0034] Wherein, the preparation method of antifreeze protein powder of Polygonum victoriae leaves comprises the following steps:

[0035] Soak the leaves of Polygonum victoriae in PBS buffer solution, centrifuge, collect the supernatant, and precipitate in saturated ammonium sulfate with a concentration of 40% to 90%, redissolve the precipitate in water, dialyze with water, and vacuum freeze-dry The antifreeze protein powder of Polygonum vermilion...

Embodiment 2

[0042] The difference with Example 1 is:

[0043] Based on the total weight of the frozen bread dough, the frozen bread dough comprises the following components: bread flour 49wt%, sugar 10.3wt%, yeast 1.3wt%, sodium chloride 0.6wt%, milk powder 2.12wt%, shortening 9.3wt% , 0.09wt% fenugreek gum, 0.09wt% tartrate monoglyceride diacetate, 24.5wt% water, 0.1wt% transglutaminase, 0.1wt% xylanase, and 2.5wt% antifreeze protein powder from Polygonum versicolor leaves. Frozen bread dough S2 is obtained, and bread S2-2 is obtained accordingly.

[0044] The power of ultrasonic assisted fermentation when preparing bread is 400W.

Embodiment 3

[0046] The difference with Example 1 is:

[0047] Based on the total weight of the frozen bread dough, the frozen bread dough comprises the following components: bread flour 48wt%, sugar 10.5wt%, yeast 1.3wt%, sodium chloride 0.52wt%, milk powder 1.8wt%, shortening 9.0wt% , 0.09wt% fenugreek gum, 0.09wt% tartrate monoglyceride diacetate, 25.5wt% water, 0.1wt% transglutaminase, 0.1wt% xylanase, and 3wt% antifreeze protein powder from Polygonum versicolor leaves. Frozen bread dough S3 is obtained, and bread S3-3 is obtained accordingly.

[0048] The power of ultrasonic assisted fermentation when preparing bread is 500W.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com