Ingredient for slowing down retrogradation of starch in grain-based nutritious rice flour and production process thereof

A technology of nutritional rice flour and production process, which is applied in application, food preparation, food science and other directions, can solve the problems of indigestion of retrograded starch, affecting the digestion and absorption of infants and young children, poor preparation of nutritional rice flour for infants and young children, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

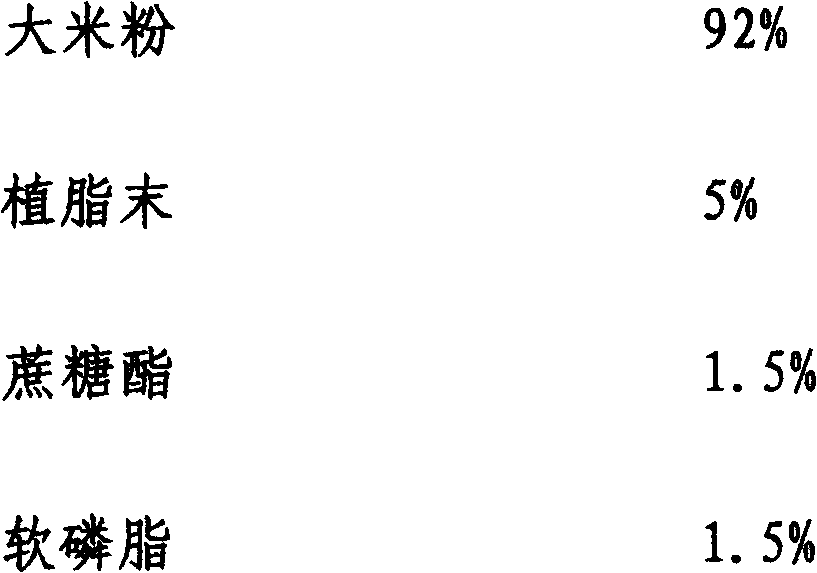

Embodiment 1

[0023]

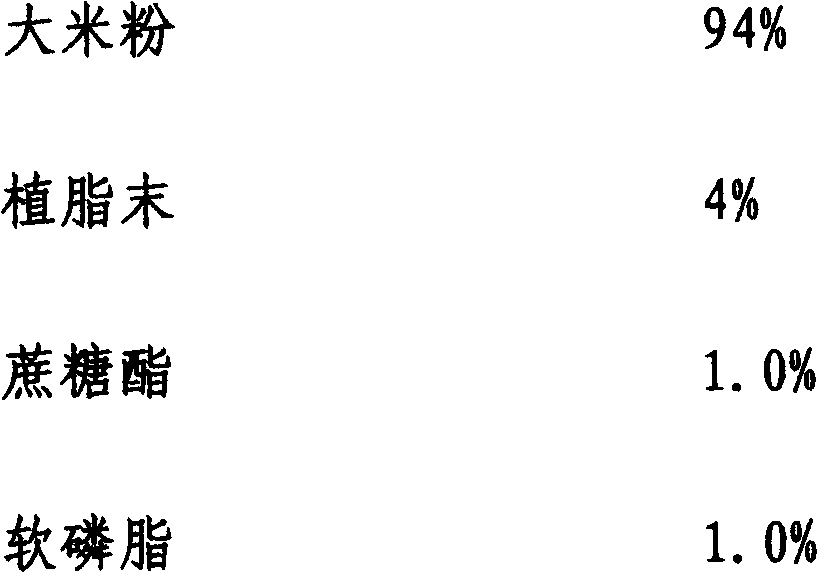

Embodiment 2

[0025]

Embodiment 3

[0027]

[0028]

[0029] Production process and operation points:

[0030] ①Soaking in water: The rice should fully absorb water and swell for more than 3 hours, which is convenient for grinding.

[0031] ②Rice is firstly and finely ground to make the grain size reach 80-100 mesh.

[0032] ③Mulching process: first fully mix the emulsifier with an appropriate amount of non-dairy creamer, then mix with the remaining non-dairy creamer, then melt all the non-dairy creamer and emulsifier mixture with an appropriate amount of hot water, and then mix with the rubber milled Rice slurry is mixed; the total water consumption is calculated based on 50-56% of the mass fraction in the slurry.

[0033] ④ Homogeneity: In order to fully mix the emulsifier and rice milk, the mixture needs to be homogeneously emulsified. The homogeneous pressure is 10 atmospheres.

[0034] ⑤ Pre-gelatinization: The homogenized mixed slurry is first heated to 50°C for pre-gelatinization.

[0035] ⑥Roll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com