Softened micro-pore barley bran dietary fibre and preparation method thereof

A technology of dietary fiber and barley bran, which is applied in the field of softening microporous barley bran dietary fiber and its preparation, can solve problems such as gluten formation hindrance and efficacy reduction, and achieve the effects of reducing negative effects, delaying aging retrogradation, and inhibiting texture hardening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

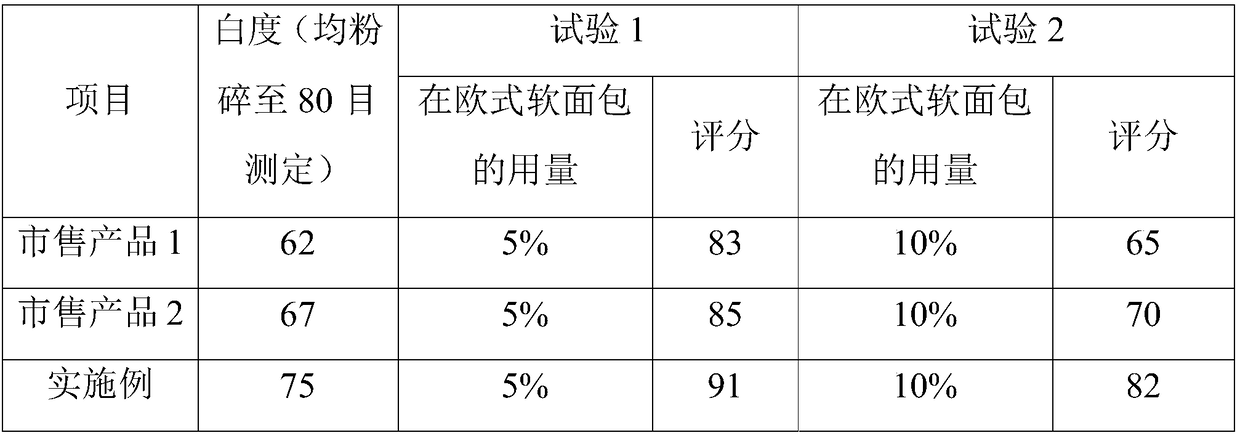

Examples

preparation example Construction

[0023] The invention provides a method for preparing softened microporous barley bran dietary fiber, comprising the steps of:

[0024] S1 (fermentation and enzymatic hydrolysis): Activate the compound starter with warm water and gradually dilute it to 200-1000 times, then fully mix it with barley bran, so that the microorganisms and enzymes are evenly distributed in the barley bran, and the water content is 28%- 45% of the mixed material; put the mixed material in a tank fermentation reactor, stack it naturally, ferment at 28-37°C, turn over and stir once every 3-5h, so that microorganisms can proliferate under aerobic conditions After 24 hours, cover the surface of the fermenter with a film (no compaction required), transfer to static microaerobic fermentation, control the temperature of the fermentation material to be 38-42°C, continue to ferment until 60-84 hours and then end the fermentation to obtain barley after fermentation and enzymolysis Bran; among them, the compound...

Embodiment

[0029] This embodiment provides a method for preparing softened microporous barley bran dietary fiber, comprising steps:

[0030] S1 (fermentation enzymatic hydrolysis): mix 1kg of compound starter (the number of live bacteria of S. 8 CFU / g, the number of live bacteria of Lactobacillus is not less than 1×10 7 CFU / g) was diluted to 50kg with warm water at 30±2°C, and then diluted to 450kg after standing for 60 minutes to obtain the diluted bacterial solution;

[0031] Fully mix the diluted bacterial solution and 1000kg of barley bran, so that the microorganisms and enzymes are evenly distributed in the barley bran, and a mixed material with a water content of 35% is obtained;

[0032] Put the mixed materials in a tank-type fermentation reactor, stack them naturally, ferment at 35±2°C, turn over and stir once every 4 hours, so that microorganisms can proliferate under aerobic conditions; after 24 hours, cover the surface of the fermentation tank Membrane (without compaction), ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com