Preparation method of anti-aging retrogradation rice

An anti-aging and rice technology, applied in food preparation, application, food science and other directions, can solve problems such as inconvenient access, and achieve the effects of reducing crystal ordering, reducing cohesion and preventing aging.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] (1) Mix water-soluble soybean protein and washed rice into water, and the mixing ratio of water-soluble soybean protein, rice, and water is 0.01:1:1.3;

[0048] (2) After the water-soluble soybean protein is completely dissolved, place it at 40°C for 30 minutes and stir it every 10 minutes;

[0049] (3) Cook at normal pressure in a rice cooker for 25 minutes; obtain anti-aging rejuvenated rice;

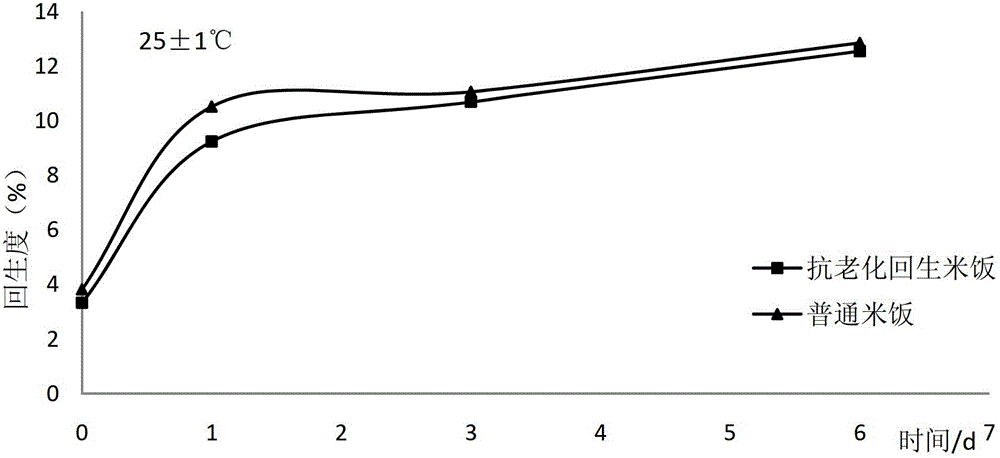

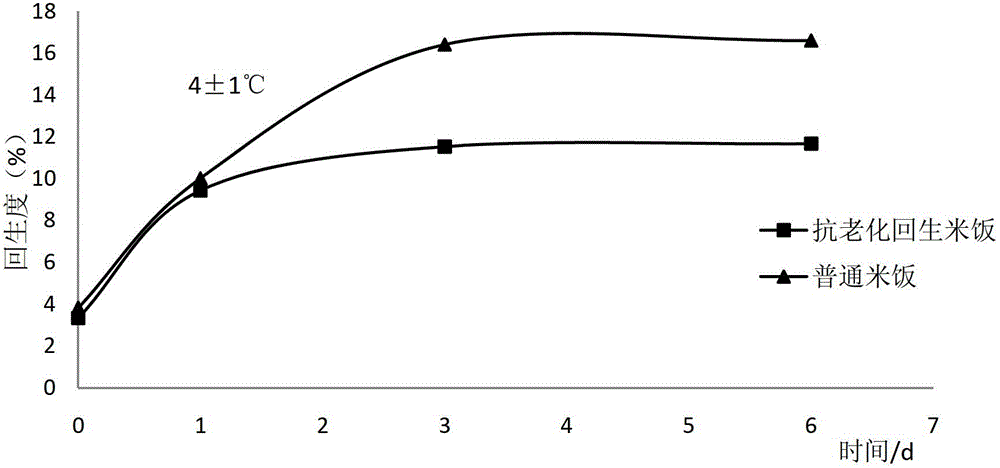

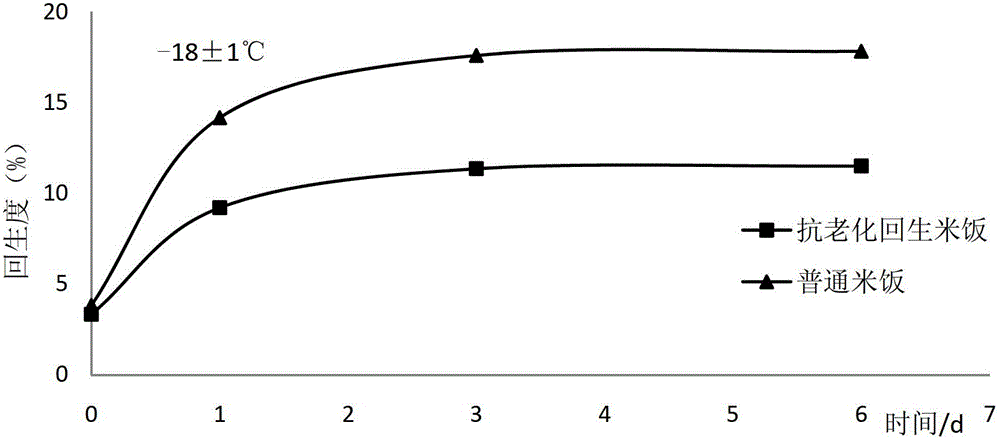

[0050] (4) Weigh an appropriate amount of anti-aging regenerated rice, store it at 25±1℃, 4±1℃, -18±1℃, and measure the fresh and anti-aging regenerated rice after storage for 1d, 3d, and 6d. Gelatinization degree and retrogradation degree; the ordinary rice obtained without adding water-soluble soybean protein was used as the control group. The measurement results are shown in Tables 1 to 4. Figures 1 to 3 .

[0051] Table 1 Gelatinization degree of fresh anti-aging retrograded rice and ordinary rice

[0052]

[0053] Table 2 Gelatinization degree and retrogradation degr...

Embodiment 2

[0065] (1) Mix water-soluble soybean protein and washed rice into water, and the mixing ratio of water-soluble soybean protein, rice, and water is 0.012:1:1.5;

[0066] (2) After the water-soluble soybean protein is completely dissolved, place it at 45°C for 25 minutes and stir it every 10 minutes;

[0067] (3) Cooking at normal pressure in a rice cooker for 25 minutes; obtaining anti-aging rejuvenated rice.

[0068] (4) Weigh an appropriate amount of anti-aging regenerated rice, store it at 25±1℃, 4±1℃, -18±1℃, and measure the fresh and anti-aging regenerated rice after storage for 1d, 3d, and 6d. Gelatinization degree and retrogradation degree; the ordinary rice obtained without adding water-soluble soybean protein was used as the control group. The measurement results are shown in Tables 5-8. Figures 4 to 6 .

[0069] Table 5 Gelatinization degree of fresh anti-aging regenerated rice and ordinary rice

[0070]

Degree of gelatinization

degree of regen...

Embodiment 3

[0084] (1) Mix seaweed protein and washed rice into water, and the mixing ratio of seaweed protein, rice and water is 0.01:1:1.3;

[0085] (2) After the seaweed protein is completely dissolved, place it at 40°C for 30 minutes and stir it every 10 minutes;

[0086] (3) Cook at normal pressure in a rice cooker for 25 minutes; obtain anti-aging rejuvenated rice;

[0087] (4) Weigh an appropriate amount of anti-aging regenerated rice, store it at 25±1℃, 4±1℃, -18±1℃, and measure the fresh and anti-aging regenerated rice after storage for 1d, 3d, and 6d. Gelatinization degree and retrogradation degree; the ordinary rice obtained without adding laver protein was used as the control group. The measurement results are shown in Tables 9 to 12. Figures 7 to 9 .

[0088] Table 9 Gelatinization degree of fresh anti-aging regenerated rice and ordinary rice

[0089]

Degree of gelatinization

degree of regeneration

Anti-aging rejuvenated rice

0.9655

3.45...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com