Agrocybe cylindracea culture medium and preparation method thereof

A culture medium and tea tree mushroom technology, which is applied in fertilization devices, fertilizer mixtures, applications, etc., can solve the problems of tea tree mushroom nutritional value and ingredients, unfavorable absorption of tea tree mushroom strains, high demand for medium configuration, etc., to achieve rich and convenient raw materials Intense mixing, manufacturing and low cost effects for production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Example 1: A tea tree mushroom medium according to the present invention, the formula and weight ratio of the medium are as follows: 15%-20% peach wood chips, 20%-25% willow wood chips; 10%-15% tea fruit Shell, 4%-6% peptone powder, 2%-4% agar strip, 3%-5% plant ash, 1%-3% gypsum.

[0026] The peach wood chips and willow wood chips described in the present invention are wood chips that have been aged outdoors through sun exposure and raining, and the mass ratio of the peach wood chips and willow wood chips is 1:1.5; the length range of the wood chips is The length is 0.8-1.5cm, which is convenient for filling and storage, and at the same time facilitates the attachment of the root system of tea tree mushroom, and the connection is stable. The tea husk of the present invention is the original husk of the tea fruit after the core removal treatment, and is stirred by a pulverizing mixer. The tea husk is a solid particle with a surface diameter of 0.5-1cm after stirring an...

Embodiment 2

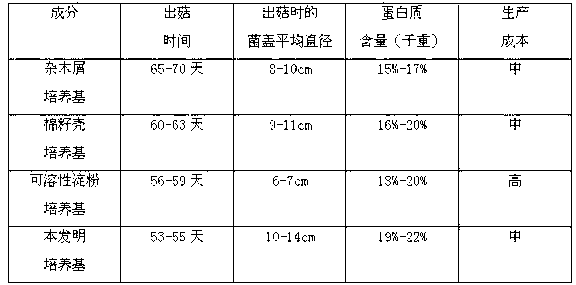

[0029] Example 2: The results of comparative tests under the same environment on the medium prepared from common sawdust, cottonseed hulls and soluble starch as the main raw materials are shown in the table below:

[0030]The preferred percentage by weight distribution ratio of various components of tea tree mushroom medium according to the present invention is as follows: 15% of peach wood chips, 22.5% of willow wood chips; 13% of tea husks, 5% of peptone powder, 3.3% of agar strips, and 4% of plant ash , gypsum 2%; the mass percentage ratio of distilled water used in the configuration medium is 129.6%.

[0031]

[0032] The culture medium of the present invention according to the comparison experiment of the culture medium that this proportioning is made and common culture medium is as shown below not only greatly shorter than other common culture medium on the fruiting time, the average diameter and the average diameter of the bacterial cap on its bacterial strain Comp...

Embodiment 3

[0033] Example 3: The configuration method of a kind of tea tree mushroom culture medium of the present invention:

[0034] 1) The branches from the peach tree and the willow tree are cut into pieces respectively, and the cut branches are crushed by different large-scale pulverizers, and the crushed particles pass through a filter screen structure with a mesh diameter of 1.5cm to obtain For branch particles with a diameter of 0-1.5cm, pass the mixed powder particles through a filter screen structure with a mesh diameter of 0.8cm to obtain branch particles with a diameter of 0.8-1.5cm, and weigh them for use;

[0035] 2) The obtained peach wood chips and willow wood chips are subjected to aging treatment respectively. The sun exposure time is 8:00-17:00 every day, and the sun exposure time is 30 days. Water treatment is carried out at night every day. The dripping pipeline device performs the showering work, and the watering time is 18:00-6:00 every day, and the watering trea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com