Solid-state lithium ion composite electrolyte membrane and preparation method thereof

A composite electrolyte membrane and lithium-ion technology, which is applied in the field of solid-state lithium-ion composite electrolyte membrane and its preparation, can solve the problems of increased energy density of all-solid-state lithium-ion batteries, low room temperature ion conductivity, and small lithium ion migration number, etc., to achieve Easy to adsorb anions, enhance solubility, and uniform shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

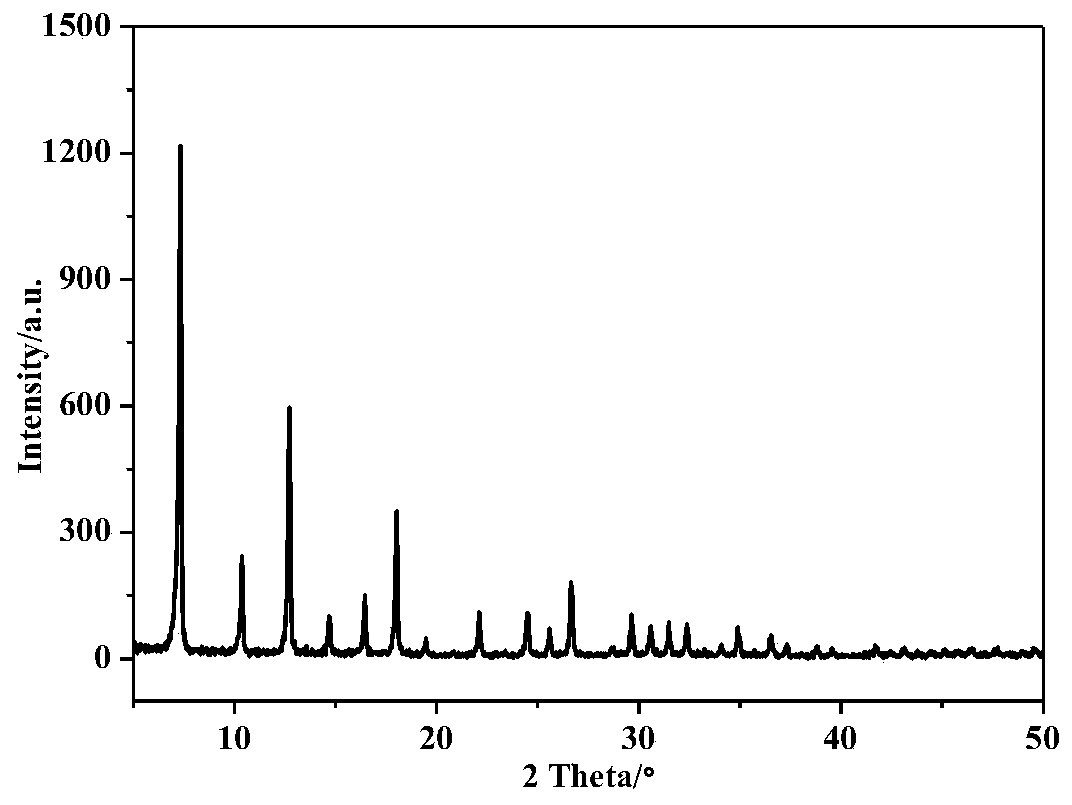

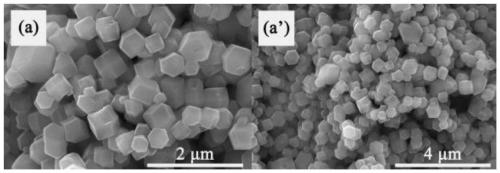

[0033] Take a 100mL clean beaker, add 25mL of methanol solvent into it, then weigh 1.4552g of cobalt nitrate and dissolve it in methanol solvent to obtain solution A; 2. Add 5133g of dimethylimidazole into a beaker filled with 25mL of methanol solvent, and magnetically stir to dissolve it completely to form solution B. Under the condition of magnetic stirring, add solution A to solution B drop by drop, let it stand for 24 hours after the dropwise addition, then centrifuge the formed precipitate at 8000 rpm for 3 minutes, and wash the precipitate with methanol for 3 times , the precipitate after centrifugation was transferred to a vacuum drying oven, and dried at a temperature of 60° C. for 12 hours to obtain an organometallic framework ZIF-67 material.

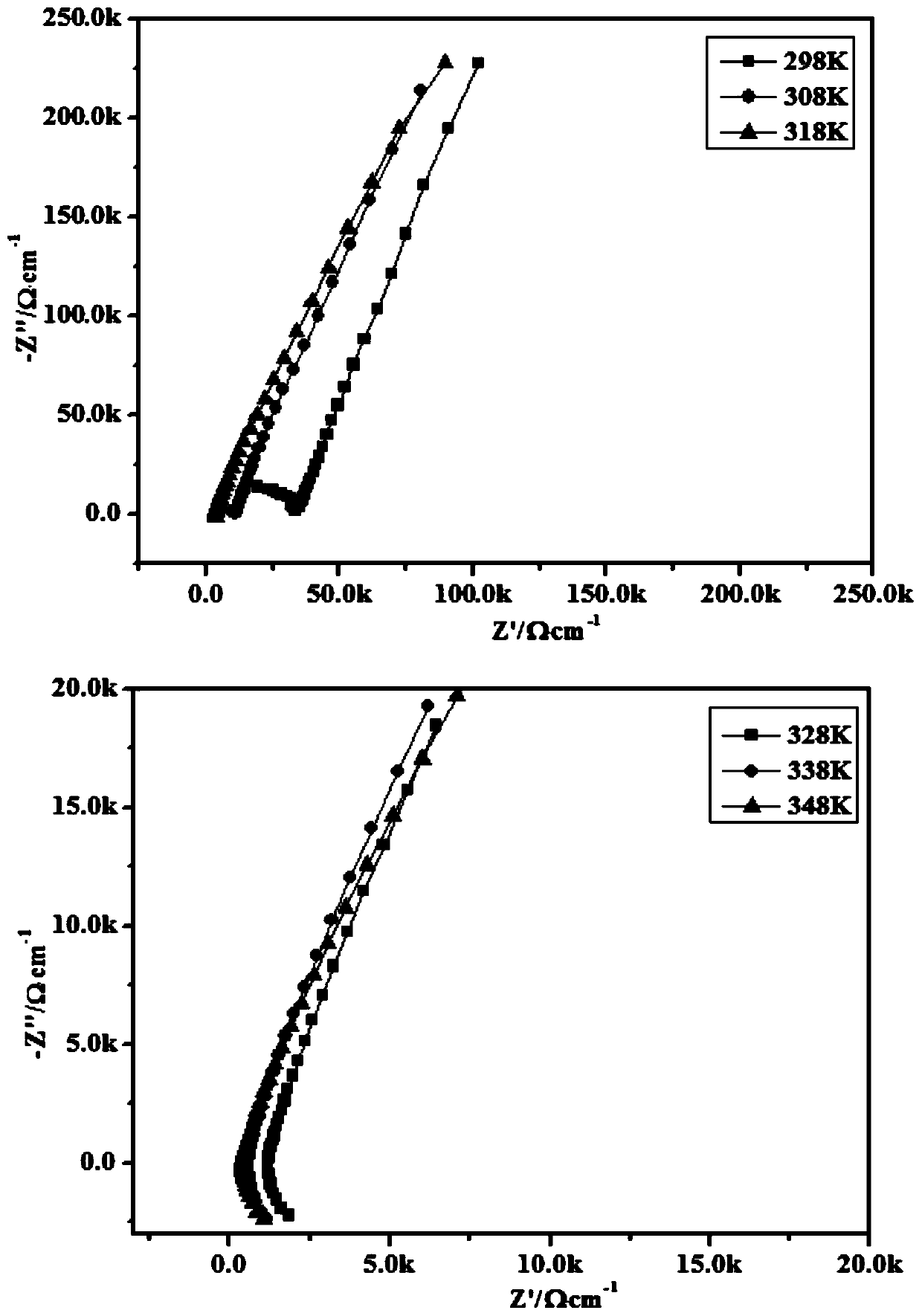

[0034] Weigh 0.6g of PEO and 0.2175g of LITFSI (the molar ratio of EO to LITFSI is 18:1), add them into 6mL of acetonitrile solvent respectively, stir them with magnetic force to make them completely dissolve, and then add 0....

Embodiment 2

[0036]Take a 100mL clean beaker, add 25mL of methanol solvent into it, then weigh 1.4552g of cobalt nitrate and dissolve it in methanol solvent to obtain solution A; 2. Add 5133g of dimethylimidazole into a beaker filled with 25mL of methanol solvent, and magnetically stir to dissolve it completely to form solution B. Under the condition of magnetic stirring, add solution A to solution B drop by drop, let it stand for 24 hours after the dropwise addition, then centrifuge the formed precipitate at 8000 rpm for 3 minutes, and wash the precipitate with methanol for 3 times , the precipitate after centrifugation was transferred to a vacuum drying oven, and dried at a temperature of 60° C. for 12 hours to obtain an organometallic framework ZIF-67 material.

[0037] Weigh 0.6g of PEO and 0.2175g of LITFSI (the molar ratio of EO to LITFSI is 18:1), add them into 6mL of acetonitrile solvent respectively, stir them with magnetic force to make them completely dissolve, and then add 0.0...

Embodiment 3

[0039] Take a 100mL clean beaker, add 25mL of methanol solvent into it, then weigh 1.4552g of cobalt nitrate and dissolve it in methanol solvent to obtain solution A; 2. Add 5133g of dimethylimidazole into a beaker filled with 25mL of methanol solvent, and magnetically stir to dissolve it completely to form solution B. Under the condition of magnetic stirring, add solution A to solution B drop by drop, let it stand for 24 hours after the dropwise addition, then centrifuge the formed precipitate at 8000 rpm for 3 minutes, and wash the precipitate with methanol for 3 times , the precipitate after centrifugation was transferred to a vacuum drying oven, and dried at a temperature of 60° C. for 12 hours to obtain an organometallic framework ZIF-67 material.

[0040] Weigh 0.6g of PEO and 0.2175g of LITFSI (the molar ratio of EO to LITFSI is 18:1), add them into 6mL of acetonitrile solvent respectively, stir them with magnetic force to make them completely dissolve, and then add 0....

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com