Low copper beryllium mold material for gravitation and low-pressure casting and production process thereof

A beryllium-copper alloy and low-pressure casting technology, which is applied in the field of low-beryllium copper alloy mold materials and its production technology, can solve the problems of reduced strength, poor thermal conductivity and electrical conductivity, etc., to suppress grain boundary reactions, improve toughness, and increase mold life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

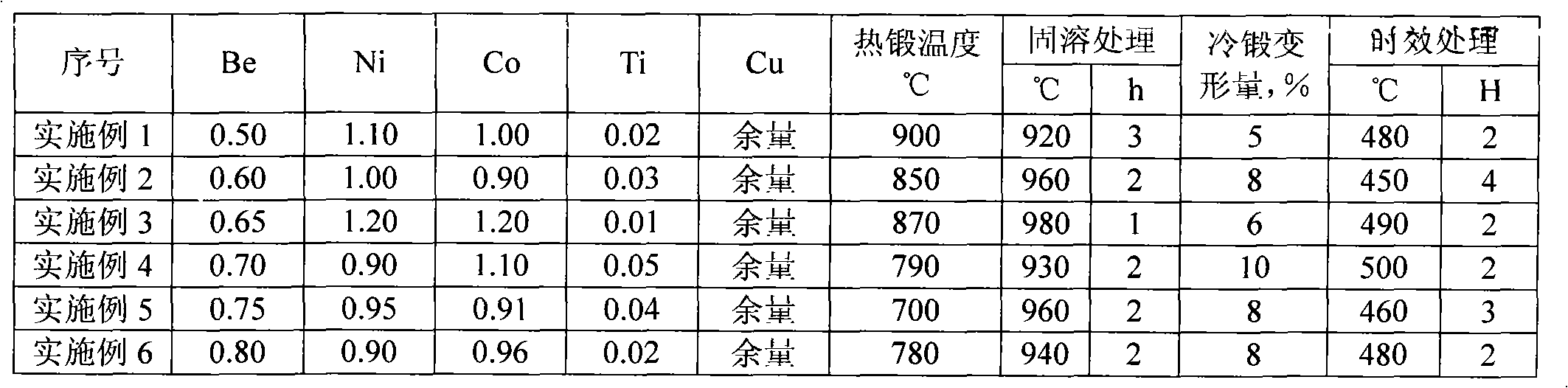

[0013] Production process: ingredients are prepared according to the set composition range, put into a vacuum medium frequency induction furnace for melting, poured into ingots, stripped, and hot forged the ingots, the hot forging temperature range is 900-700 ° C, and the hot forging deformation is ≥ 50%; The ingot after hot forging is subjected to solid solution treatment, the treatment temperature is 920-980°C, and the treatment time is 1-3h; after the ingot is treated, it is quenched in water, the entering water temperature shall not be less than 900°C, and the cooling water temperature shall not be greater than 50°C; The forging is cold forged, and the cold forging deformation is 5-10%; aging treatment is carried out at a temperature of 450-500 ° C for 2-4 hours.

[0014] The low-beryllium copper alloy mold material for gravity and low-pressure casting of the present invention produced by the above-mentioned production process, six embodiments are listed in Table 1 below, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com