Controlled directional solidification nickel-base high-temperature alloy recrystallizing method

A nickel-based superalloy, directional solidification technology, applied in chemical instruments and methods, crystal growth, post-processing details, etc., can solve the problem of unsuitable thin-walled single crystal superalloys, reduce residual stress, reduce recrystallization, The effect of depleting stored energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 3

[0033] Example 3 DZ125L directionally solidified nickel-based superalloy recrystallization control.

[0034] The DZ125L directionally solidified nickel-based superalloy plate was prepared by the directional solidification equipment, and a 2×12×12mm square was cut from the plate by wire cutting. Polish the plane of 12×12 (direction of oriented columnar crystal growth), and perform sandblasting treatment with a sandblasting device. The sandblasting parameters are as follows: the sandblasting pressure is 0.3MPa, the sandblasting time is 1min, and the sand particles are Si0 2 Glass ball.

[0035] The coating is applied by arc ion plating equipment, and the coating is C / NiCoCrAlYSiB. During the coating process, a layer of graphite is firstly coated, and the coating time is 1 hour, and then a layer of NiCoCrAlYSiB is coated, and the coating time is 8 hours. The prepared samples are coated samples.

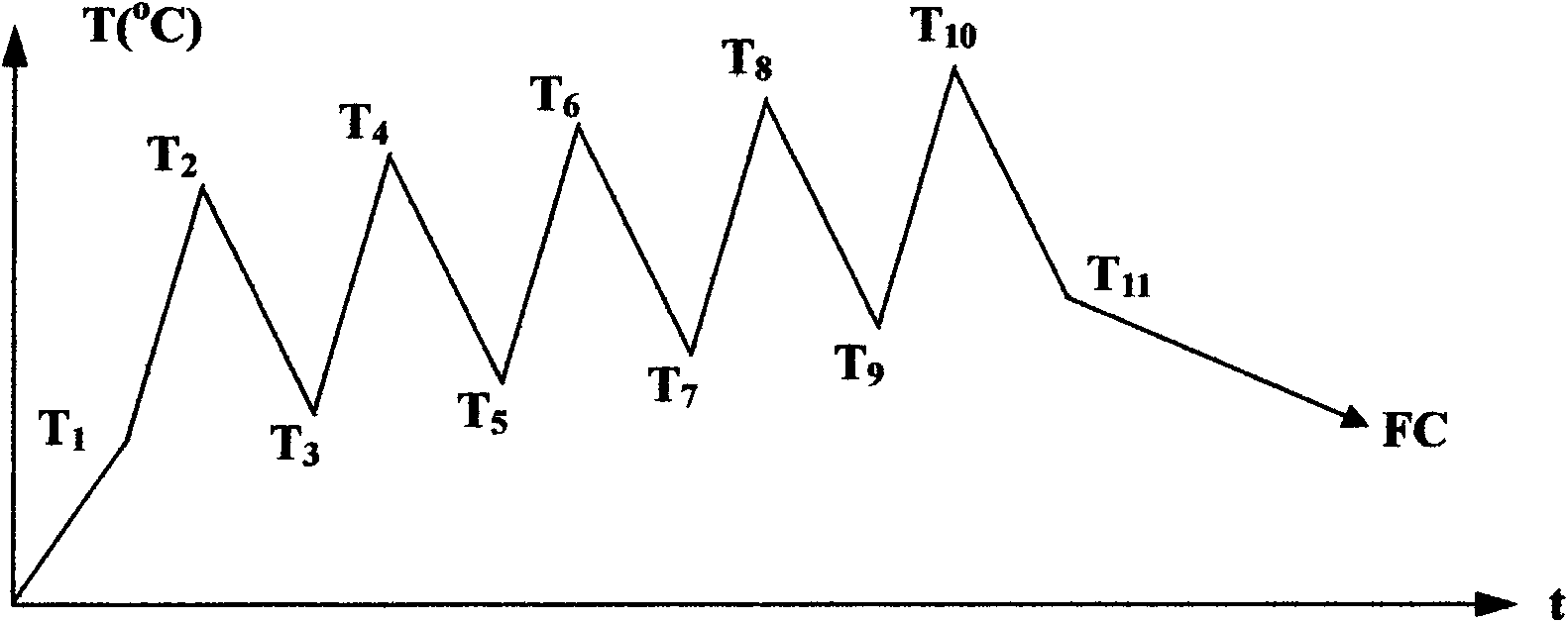

[0036] Next, turn on the heat treatment furnace and set the heat treatment progr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com