Method for controlling recrystallization of directionally solidified Ni-based superalloy by alumetizing

A nickel-based superalloy, directional solidification technology, applied in chemical instruments and methods, crystal growth, solid-state diffusion coating, etc., can solve the problems of easy oxidation of alloy matrix, complicated equipment, complicated operation, etc. The effect of reducing crystallization and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

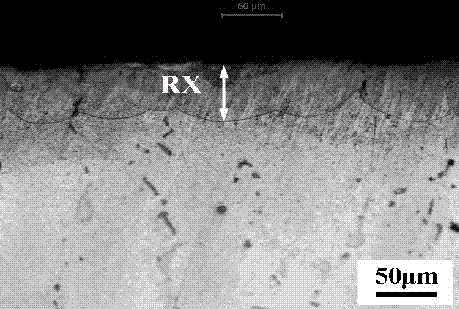

[0030] Example 1 Aluminizing Controls Recrystallization of DZ125L Alloy

[0031] The DZ125L directionally solidified nickel-based nickel-based superalloy plate was prepared by the directional solidification equipment, and a 2×12×12mm square was cut from the plate by wire cutting. Polish the surface of 12×12 (direction of oriented columnar crystal growth), and perform sandblasting treatment with a sandblasting device. Sandblasting parameters are as follows: sandblasting pressure is 0.3MPa, sandblasting time is 1min, and the sand particles are SiO 2 Glass ball.

[0032] Prepare the osmotic agent, the used osmotic agent formula is as follows: 40% Al powder, 55% Al 2 o 3 Powder and 5% NH 4 Cl (weight percent). Among them, the particle size of Al powder is Al 2 o 3 The particle size of the powder is Next, mix part of the sandblasted samples into the infiltrating agent, put them into a heat treatment furnace, raise the temperature to 600°C to start aluminizing, and pass t...

Embodiment 2

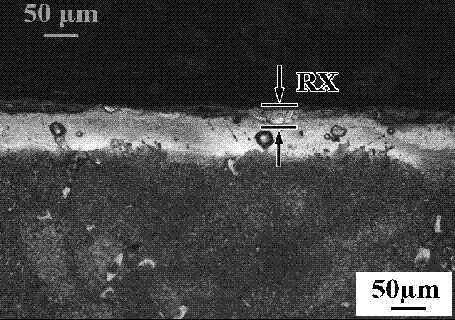

[0034] Example 2 Aluminizing Controls Recrystallization of DZ125L Alloy

[0035] The DZ125L directionally solidified nickel-based nickel-based superalloy plate was prepared by the directional solidification equipment, and a 2×12×12mm square was cut from the plate by wire cutting. Polish the surface of 12×12 (direction of oriented columnar crystal growth), and perform sandblasting treatment with a sandblasting device. Sandblasting parameters are as follows: sandblasting pressure is 0.3MPa, sandblasting time is 1min, and the sand particles are SiO 2 Glass ball.

[0036] Prepare the osmotic agent, the used osmotic agent formula is as follows: 50% Al powder, 40% Al 2 o 3 Powder and 10% NH 4 Cl (weight percent). Among them, the particle size of Al powder is Al 2 o 3 The particle size of the powder is Next, mix part of the sandblasting samples into the infiltrating agent, put them into a heat treatment furnace, raise the temperature to 600°C to start aluminizing, and pass...

Embodiment 3

[0038] Example 3 Aluminizing Controls Recrystallization of DZ17G Alloy

[0039] The DZ17G directionally solidified nickel-based nickel-based superalloy plate was prepared by the directional solidification equipment, and a 2×12×12mm square was cut from the plate by wire cutting. Polish the surface of 12×12 (direction of oriented columnar crystal growth), and perform sandblasting treatment with a sandblasting device. Sandblasting parameters are as follows: sandblasting pressure is 0.3MPa, sandblasting time is 1min, and the sand particles are SiO 2 Glass ball.

[0040] Prepare the osmotic agent, the used osmotic agent formula is as follows: 40% Al powder, 55% Al 2 o 3 Powder and 5% NH 4 Cl (weight percent). Among them, the particle size of Al powder is al 2 o 3 The particle size of the powder is Next, mix part of the sandblasting samples into the infiltrating agent, put them into a heat treatment furnace, raise the temperature to 600°C to start aluminizing, and pass th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com