Bread anti-aging baking oil and preparing method thereof

An anti-aging and baking technology, applied in the fields of edible oil/fat, baking, dough processing, etc., can solve the problems of insignificant effect of bread, poor taste of bread, discarding, etc., achieve good elasticity, improve softness, improve quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

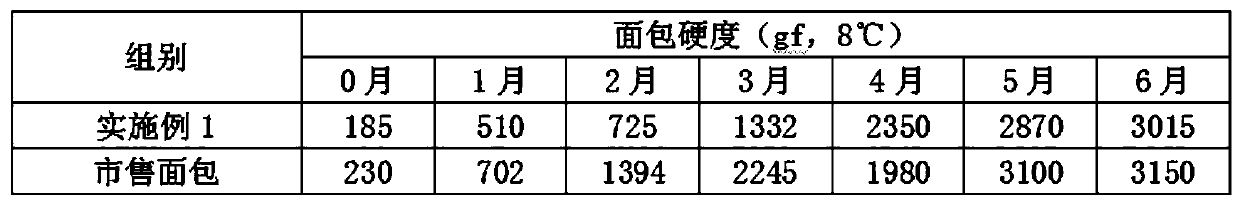

Embodiment 1

[0037] An anti-aging baking oil for bread, which includes the following components: oil base, emulsifier, amylase, food spices, β-carotene pigment and tert-butyl hydroquinone;

[0038] The oil base includes palm olein, palm stearin, soybean oil, rapeseed oil, tallow, cream, coconut oil, palm kernel oil;

[0039] The emulsifier includes mono- and diglyceride fatty acid esters, phospholipids, sodium stearoyl lactylate, polyglycerol fatty acid esters, propylene glycol fatty acid esters, diacetyl tartaric acid mono-diglycerides;

[0040] The amylases include α-amylase, xylanase, maltose amylase.

[0041] Specifically, the addition amount of each component in Example 1 is shown in Table 1.

[0042] The preparation method of the above-mentioned bread anti-aging baking fat comprises the following preparation steps:

[0043] A. Heat the oil base and emulsifier to 70°C to melt and mix uniformly to obtain oil phase a;

[0044] B. Take part of the oil phase a prepared in step A and mix ...

Embodiment 2

[0049] A kind of bread anti-aging baking fat, the raw materials added in Example 2 and the addition amount of each raw material component are shown in Table 1.

[0050] Implement the preparation method of the bread anti-aging baking grease of 2, it comprises following preparation steps:

[0051] A. Heat the oil base and emulsifier to 60°C to melt and mix them uniformly to obtain oil phase a;

[0052] B. Take part of the oil phase a prepared in step A and mix it with tertiary butyl hydroquinone and heat it to 135°C to completely melt the tertiary butyl hydroquinone, then stir it evenly and add it to the remaining oil phase a. The stirring speed is 50rpm, the stirring time is 0.5h, and the oil phase b is obtained;

[0053] C. Cool the oil phase b prepared in step B to 50° C., then add amylase, pigment and food essence and stir evenly to obtain a mixed material;

[0054] D. Pump the mixed material in step C into the rotary scraper type quenching heat exchanger, pass liquid ammo...

Embodiment 3

[0057] A kind of bread anti-aging baking fat, the raw materials added in Example 3 and the addition amount of each raw material component are shown in Table 1.

[0058] The preparation method of the bread anti-aging baking grease of embodiment 3, it comprises following preparation steps:

[0059] A. Heat the oil base and emulsifier to 80°C to melt and mix them uniformly to obtain oil phase a;

[0060] B. Take part of the oil phase a prepared in step A and mix it with tertiary butyl hydroquinone and heat it to 140°C to completely melt the tertiary butyl hydroquinone, then stir it evenly and add it to the remaining oil phase a, The stirring speed is 100rpm, the stirring time is 1h, and the oil phase b is obtained;

[0061] C. Cool the oil phase b prepared in step B to 60° C., then add amylase, pigment and food essence and stir evenly to obtain a mixed material;

[0062] D. Pump the mixed material in step C into the rotary scraper type quenching heat exchanger, pass 20°C liquid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com