Cooling device for cryogenic cooling of an NMR detection system with the assistance of a container filled with a cryogenic fluid

a cryogenic cooling and detection system technology, applied in the field of cryogenic probe heads, can solve the problems of mechanical vibration transmission into the probe head, easy to be influenced by interference, and high installation and operation costs, and achieve the effect of reducing the consumption of cryogenic liquid, reducing the influence of vibration, and simplifying the closed-loop control of the ratio of vg

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

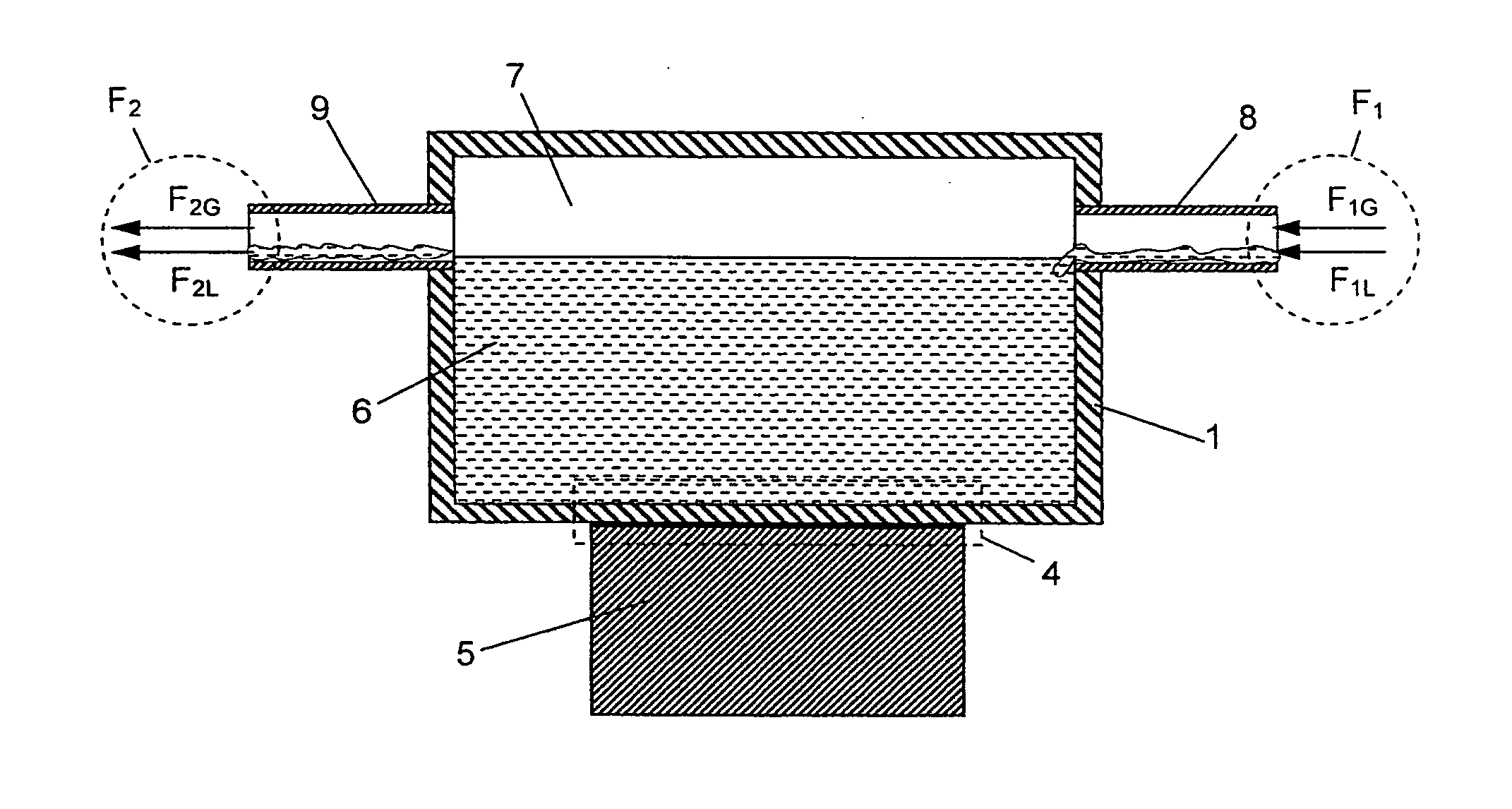

[0066]The inventive device is intended to cool in an NMR detection device the NMR resonator and various components to cryogenic temperatures by means of evaporation of a cryogenic fluid largely reduce the influence of vibration that can arise due to the cooling operation and interferes with the NMR signal, and, in particular, keep consumption of the cryogenic fluid as low as possible.

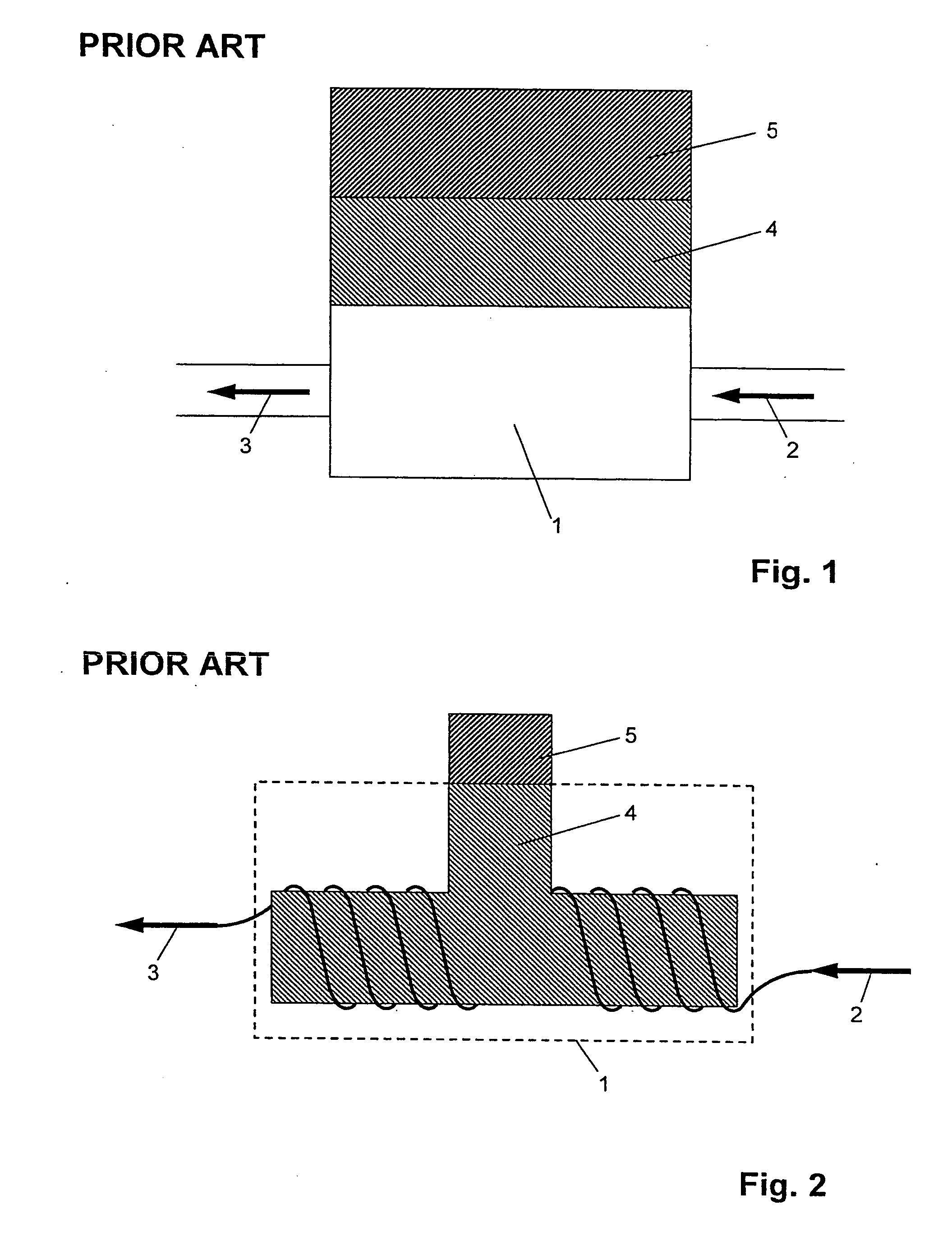

[0067]FIG. 1 shows a heat exchanger according to the prior art with a heat exchanger 1 into which an inflow 2 of coolant flows and from which an outflow 3 of coolant exits. A heat source 5 is connected thermally conductively and permanently to a contact element 4 made of material with good thermal conduction that ensures heat transfer from the heat source to the heat exchanger.

[0068]A further embodiment of the prior art is shown in FIG. 2. Here, the contact element 4 with a T shape is located in the interior of the heat exchanger 1 while the coolant is routed helically around the contact element 4.

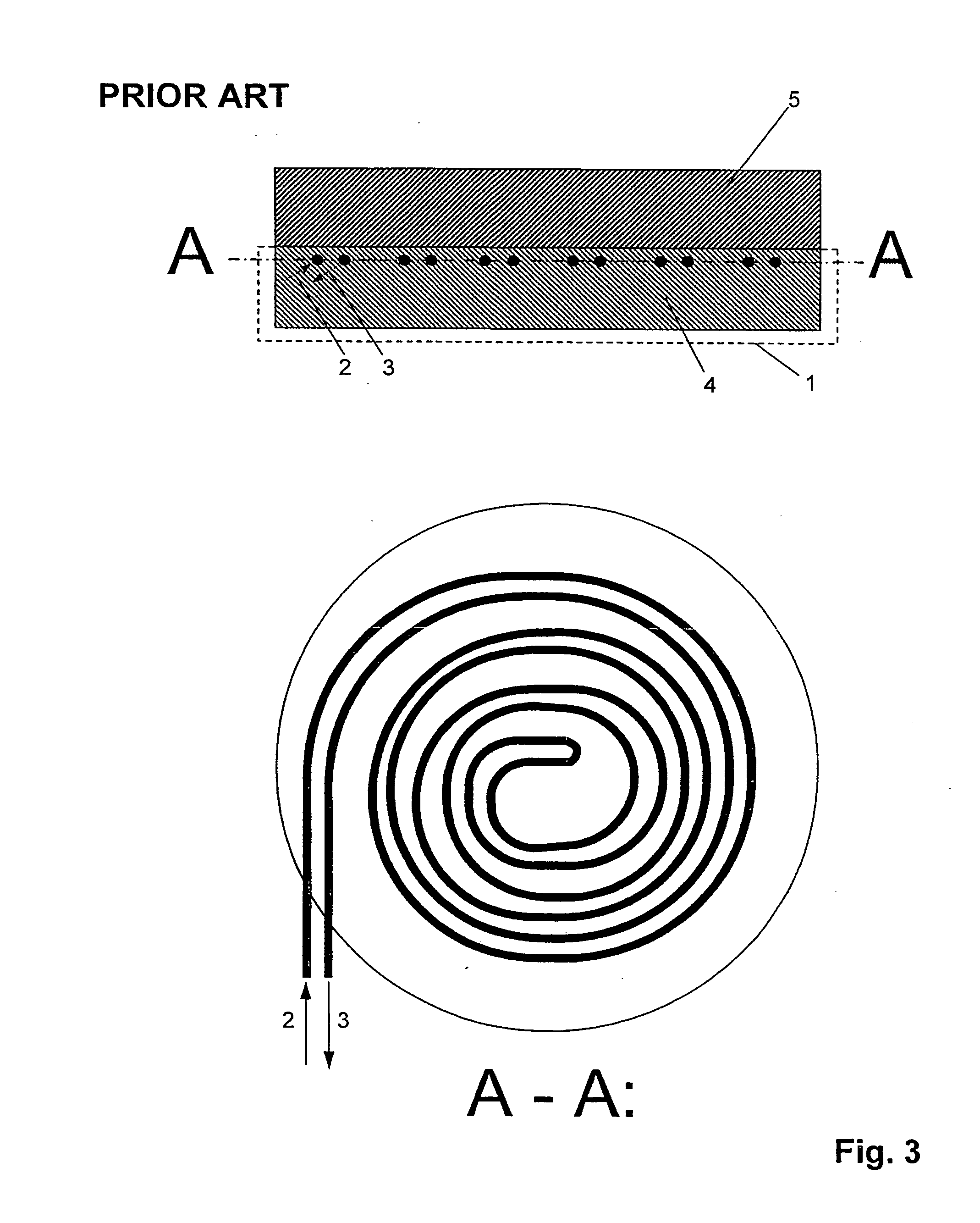

[0069...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com