Equipment for manufacturing stainless steel clad plates by low temperature induction heating

A technology for induction heating and manufacturing equipment, applied in induction heating control, induction heating, induction heating devices and other directions, can solve the problems of large equipment, high production cost, poor working environment, etc., to reduce production costs, reduce unit energy consumption, Avoid the effect of surface oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

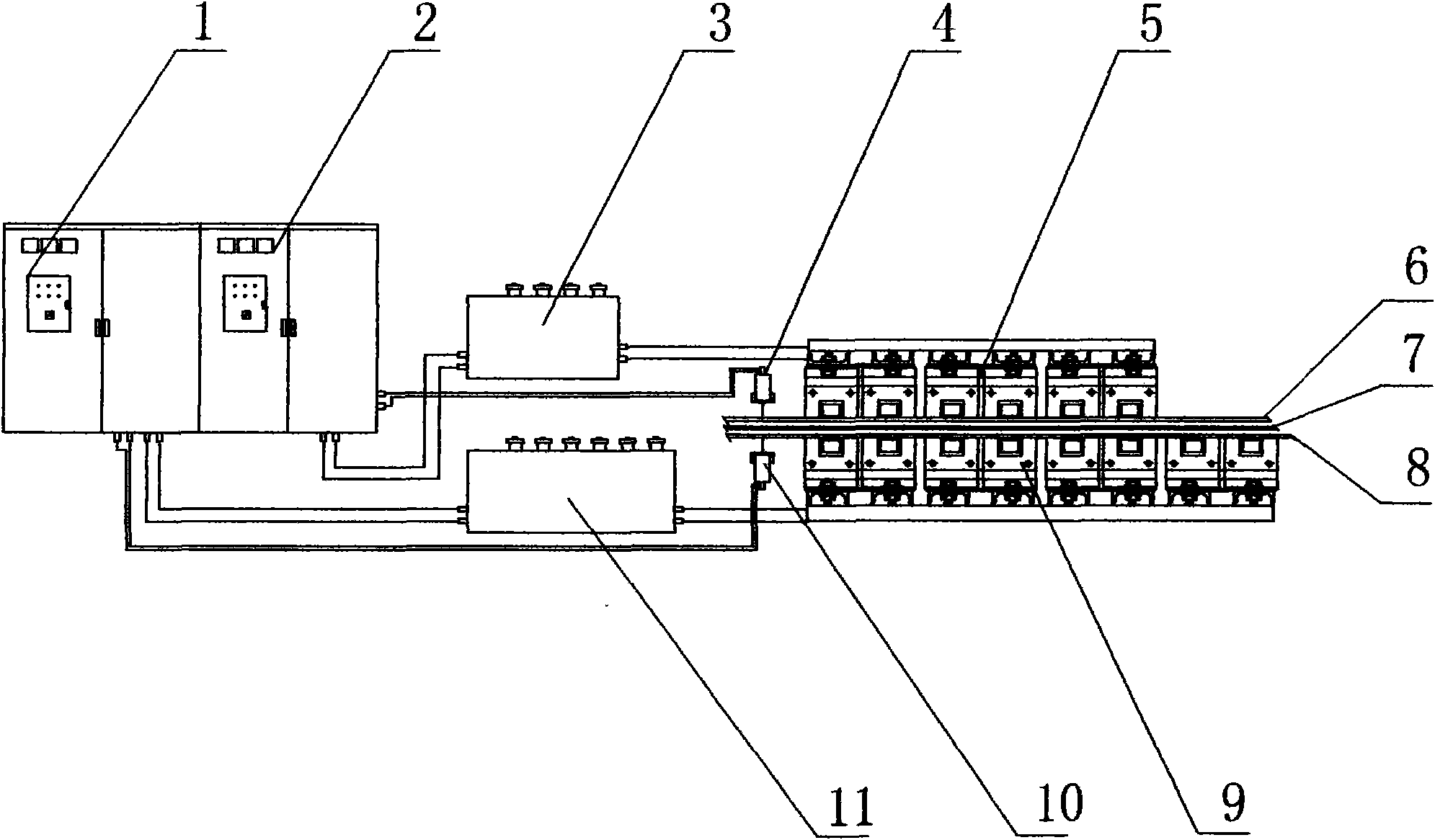

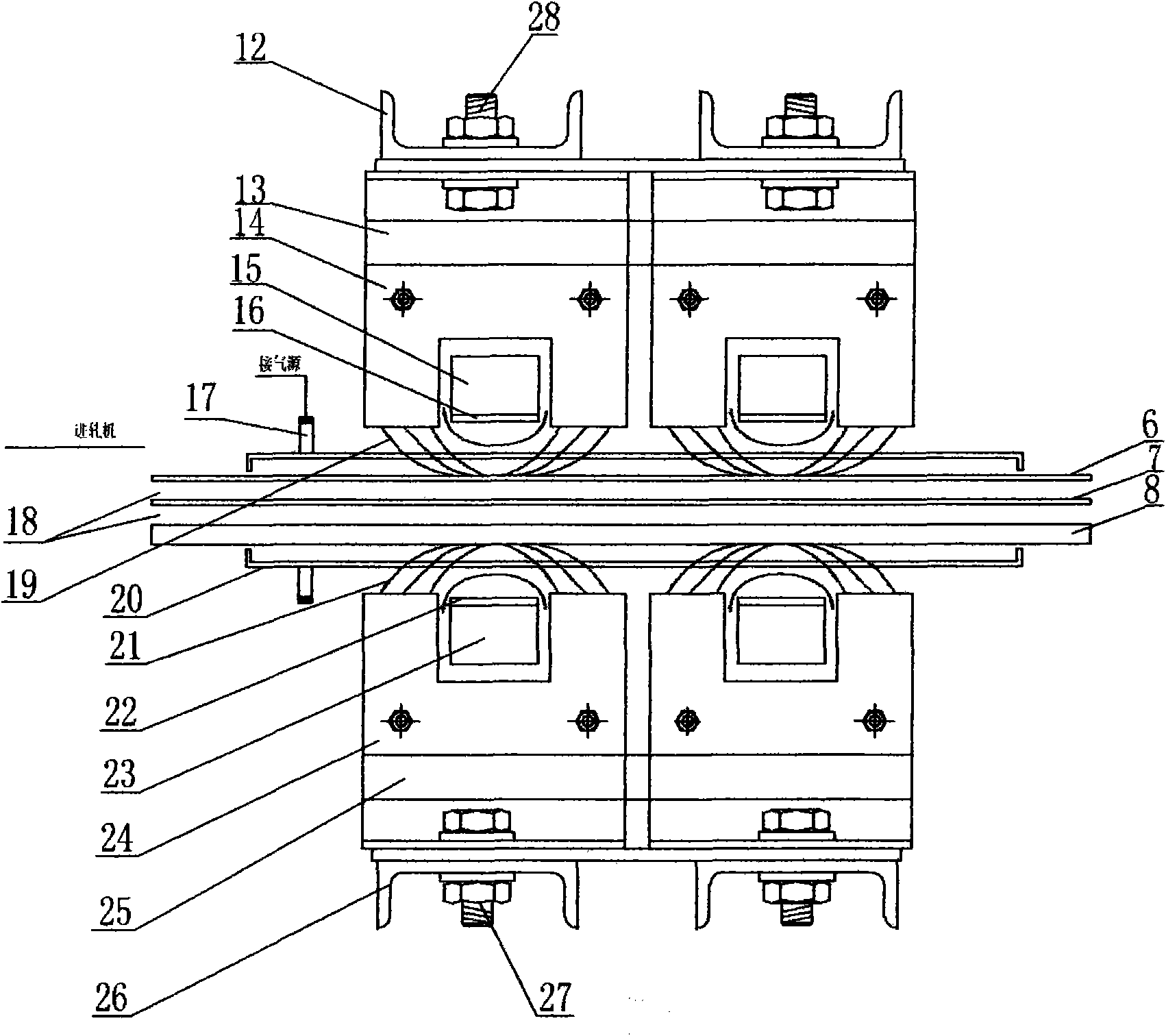

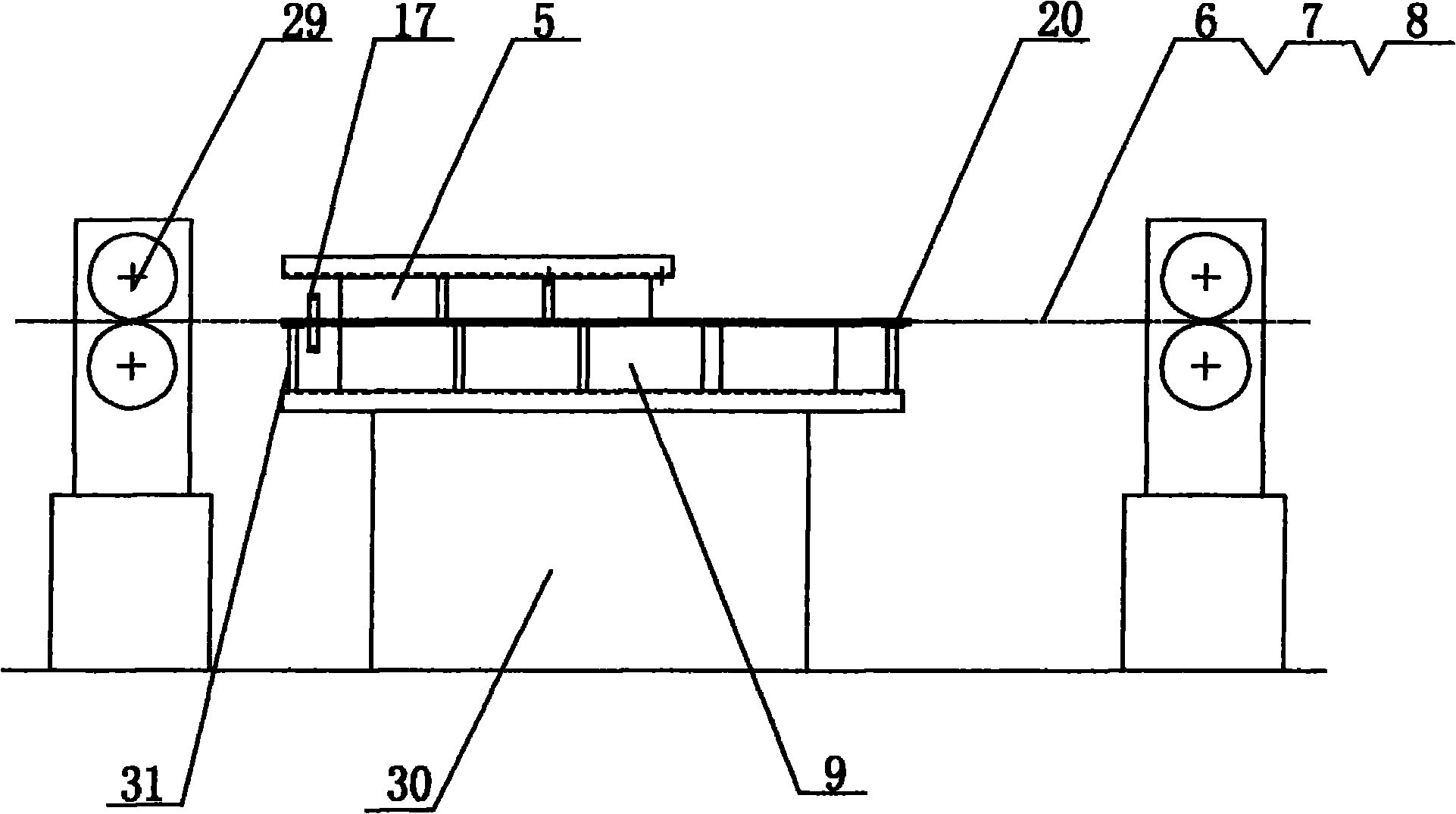

[0019] like figure 1 As shown, intermediate frequency power supply heating control system 1 and intermediate frequency power supply heating control system 2 are respectively connected to main induction heater 9 and auxiliary induction heater 5 through intermediate frequency capacitor compensator 11 and intermediate frequency capacitor compensator 2, and the main induction heater There is a metal layer between the device 9 and the auxiliary induction heater 5, and the metal layer is composed of a surface layer metal 6, an adhesive metal layer 7 and a base metal 8, and the intermediate frequency power supply heating control system 1 and the intermediate frequency power supply heating control system 2 are respectively connected with The first thermometer 10 and the second thermometer 4 are connected, and the first thermometer 10 and the second thermometer 4 are close to the base metal 8 and the surface metal 6 respectively.

[0020] Intermediate frequency power supply heating con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com