Copper alloy continuous extrusion method and special apparatus

A technology of extrusion equipment and extrusion method, applied in metal extrusion control equipment, metal extrusion, metal processing equipment, etc., can solve the problems of increased labor intensity, difficult continuous extrusion tools, long production cycle, etc. Reduce energy consumption and processing costs, significant economic and social benefits, and simplify the effect of drawing process production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

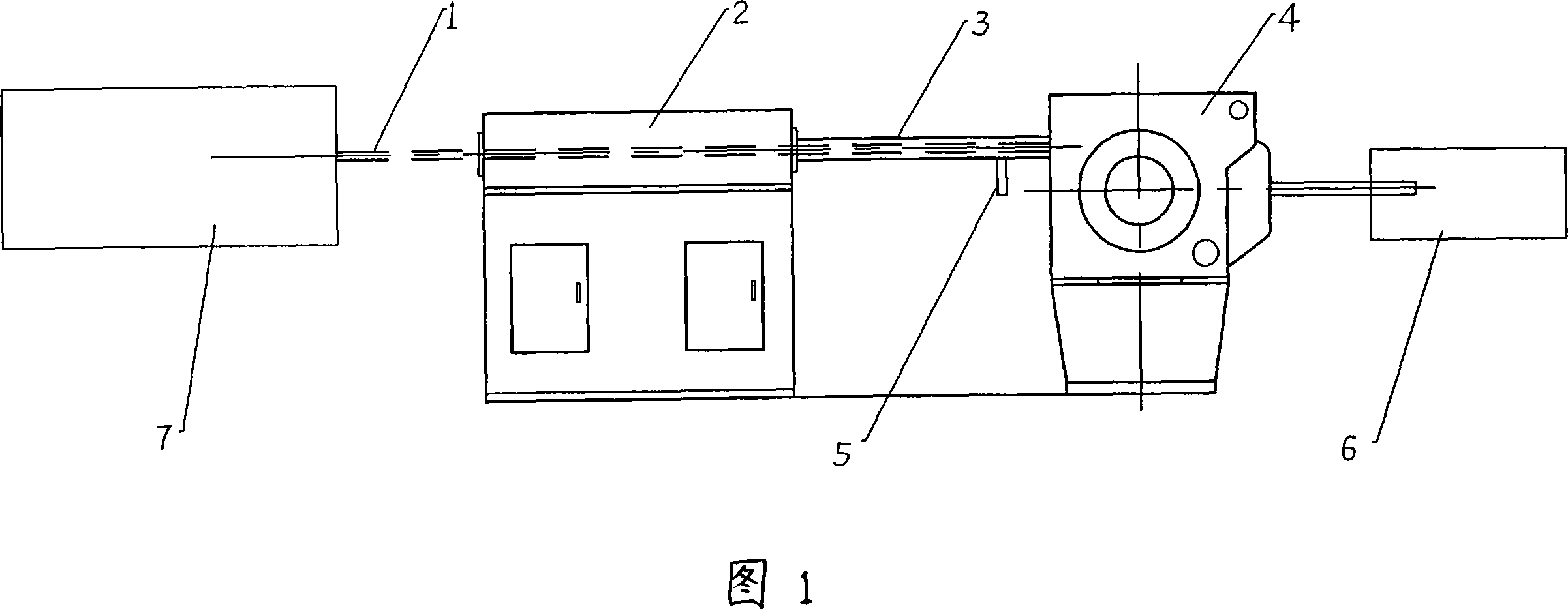

[0017] As shown in FIG. 1 , the equipment includes a bar material pretreatment device 7 , a heating device 2 , an oxidation protection device 3 , a continuous extruder 4 , a temperature measurement sensor 5 , and a product processing device 6 .

[0018] A kind of brass continuous extrusion method adopts the equipment shown in Figure 1 to carry out continuous extrusion, at first the copper rod 1 is released through the rod material pretreatment device 7, and the straight copper rod enters the heating device 2, and the heating device 2 is The furnace containing the induction heating coil is heated, and the heating temperature is measured by the temperature measurement sensor 5, and dynamically compared with the set temperature, and the heating power is adjusted through the electrical control system to ensure that the heating temperature of the rod material is within the set temperature range Inside. After the copper rod is heated, it passes through the anti-oxidation protection ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com