Sintering furnace for silicon nitride ceramic sintering and working method of sintering furnace

A silicon nitride ceramics and sintering furnace technology, applied in the field of sintering furnaces, can solve problems such as inability to ensure uniformity of sintering temperature, product hardness, adverse effects on strength, uneven heating temperature, etc., so as to improve sintering efficiency and reduce the impact , The effect of continuous and uniform heating temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] When the high-pressure gas passed into the pipeline device 4 does not reach the heating temperature;

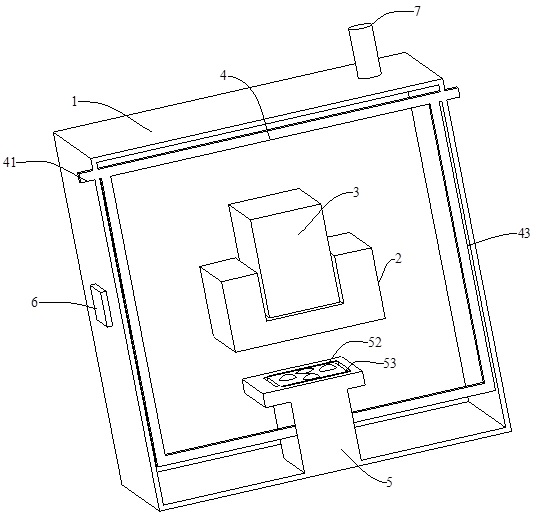

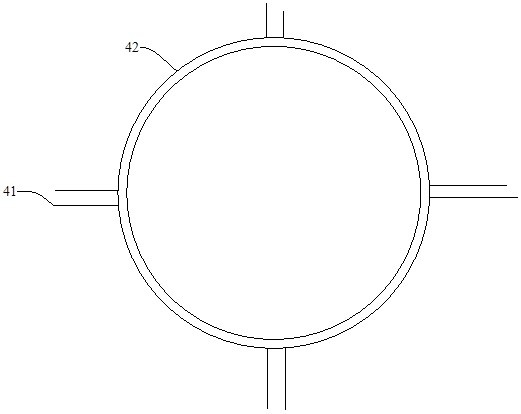

[0058] Such as Figure 1~8 As shown, a sintering furnace for sintering silicon nitride ceramics is provided. The sintering furnace includes a furnace body 1 and a heating element 2. The heating element 2 is arranged inside the furnace body 1. The heating element 2 is an electric heating element, such as a carbon rod, a carbon tube The heating element 2 is fixedly connected in the furnace body 1 through a support frame, and the crucible 3 carried on the heating element 2 is arranged on the heating element 2 for heating. The sintering furnace for sintering silicon nitride ceramics also includes a A pipeline device 4 for transmitting high-pressure gas, wherein the pipeline device 4 is suitable for transmitting the high-pressure gas that has not reached the heating temperature to the lower part of the heating element 2 . The high-pressure gas that does not reach the heati...

Embodiment 2

[0064] When the high-pressure gas passed into the pipeline device 4 reaches the heating temperature;

[0065] Such as Figure 1~7 and Figure 9 As shown, a sintering furnace for sintering silicon nitride ceramics is provided. The sintering furnace includes a furnace body 1 and a heating element 2. The heating element 2 is arranged inside the furnace body 1. The heating element 2 is an electric heating element, such as a carbon rod, a carbon tube The heating element 2 is fixedly connected in the furnace body 1 through a support frame, and the crucible 3 carried on the heating element 2 is arranged on the heating element 2 for heating. The sintering furnace for sintering silicon nitride ceramics also includes a The pipeline device 4 for transmitting high-pressure gas, wherein the pipeline device 4 is suitable for transmitting the high-pressure gas to the lower part of the heating element 2 . The high-pressure gas is injected into the furnace body 1 through the pipeline device ...

Embodiment 3

[0078] The third embodiment is carried out on the basis of the above embodiments.

[0079] This embodiment provides a working method of a sintering furnace for sintering silicon nitride ceramics.

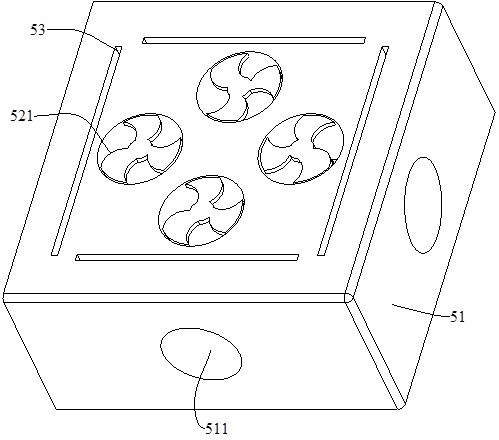

[0080]A plurality of guide chambers 53 are provided on the adjustment table 51, and each guide chamber 53 is adapted to a plugging vertical passage 5121 of a sealing chamber 512; A 45° inclined platform 5123 is set at the junction of the vertical blocking channel 5121 and the blocking horizontal channel 5122, and the 45° inclined platform 5123 ensures that the incident angle and the reflection angle are consistent, so that the high-pressure gas in the blocking cavity 512 can flow out; and the diversion cavity 53 includes a trapezoidal cavity 531 and a vertical cavity 532 that communicate with each other. The larger bottom surface of the trapezoidal cavity 531 communicates with the vertical cavity 532 , and the smaller bottom surface of the trapezoidal cavity 531 communicates with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com