A fiber manufacturing device for weaving

A technology for manufacturing devices and fibers, applied in the textile field, can solve problems such as uneven silk output, and achieve the effects of uniform thickness, good promotion and utilization value, and convenient subsequent processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Embodiment of the present invention is described below in conjunction with accompanying drawing, embodiment does not constitute limitation of the present invention:

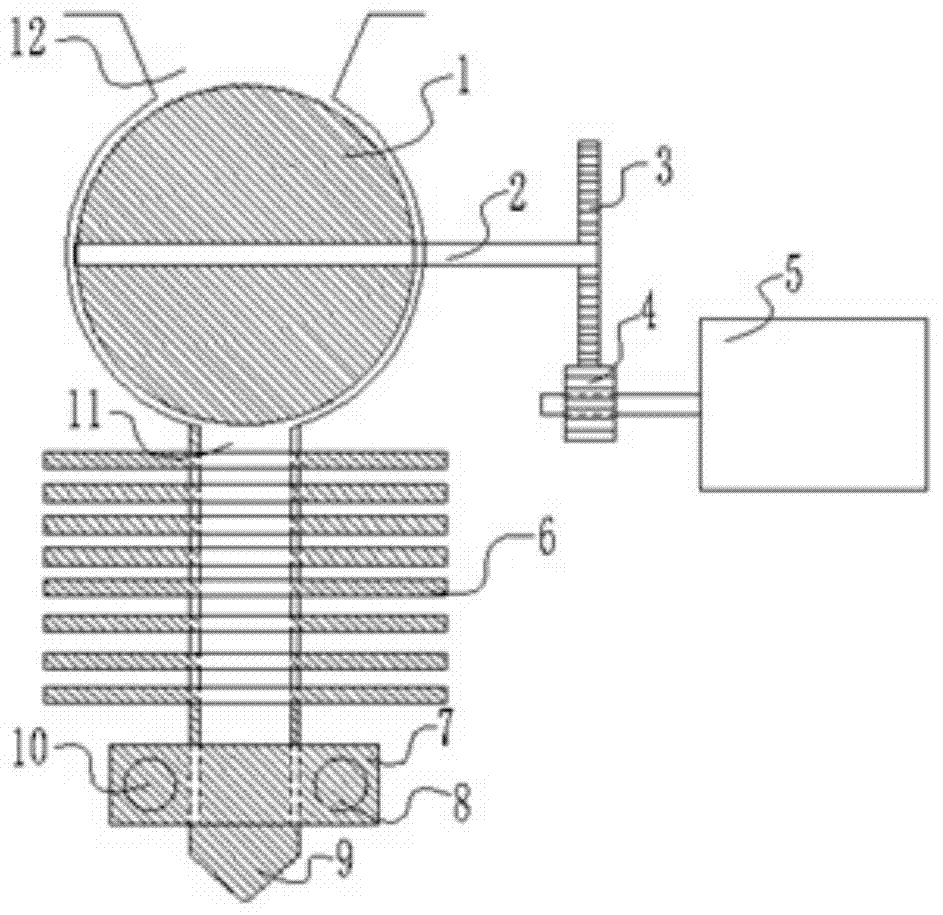

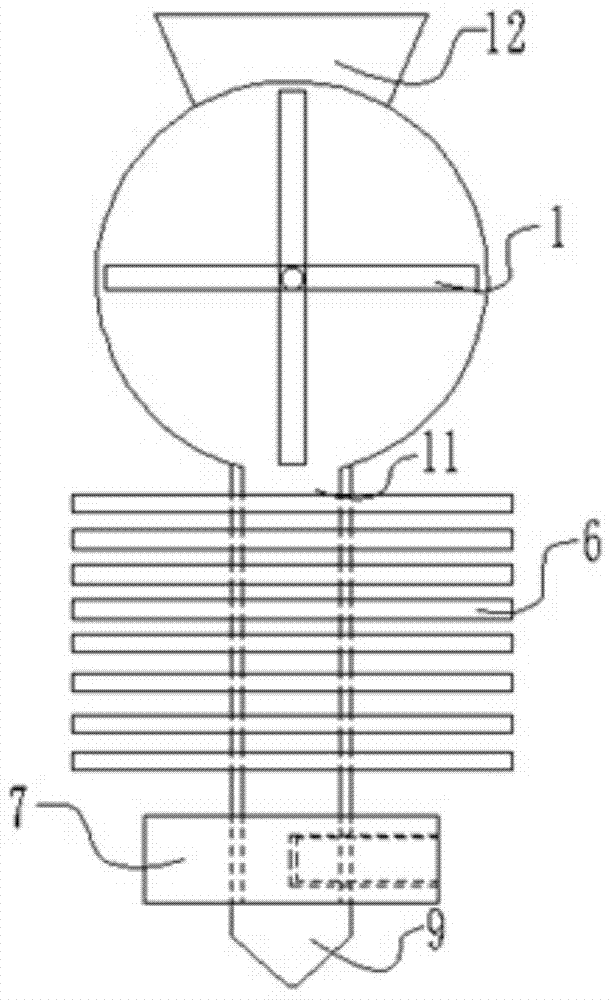

[0018] like figure 1 , figure 2 As shown, this kind of fiber manufacturing device for weaving has a structure comprising a feed inlet 12, and the lower end of the feed inlet 12 is provided with a stirring blade 1, and the stirring blade 1 is connected with a transmission rod 2, and the transmission rod 2 and the first gear 3 Connected, the first gear 3 is meshed with the second gear 4, and the second gear 4 is connected with a motor 5. When in use, the second gear 4 can be driven by the motor 5, and then through the transmission of the first gear 3 and the transmission rod 2 to make The stirring blade 1 rotates, and the stirring blade 1 fully stirs the fiber slurry, so that the fiber slurry enters the connecting rod 11 more evenly.

[0019] In the above example, specifically, the bottom of the stirring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com