Temperature-controlled resistor housing of preheating welding wire

A technology of resistance and welding wire, applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve the problems of low resistivity, low efficiency of non-magnetic material welding wire preheating temperature measuring line, complicated preheating process, etc., and achieve welding efficiency High, good preheating effect, simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

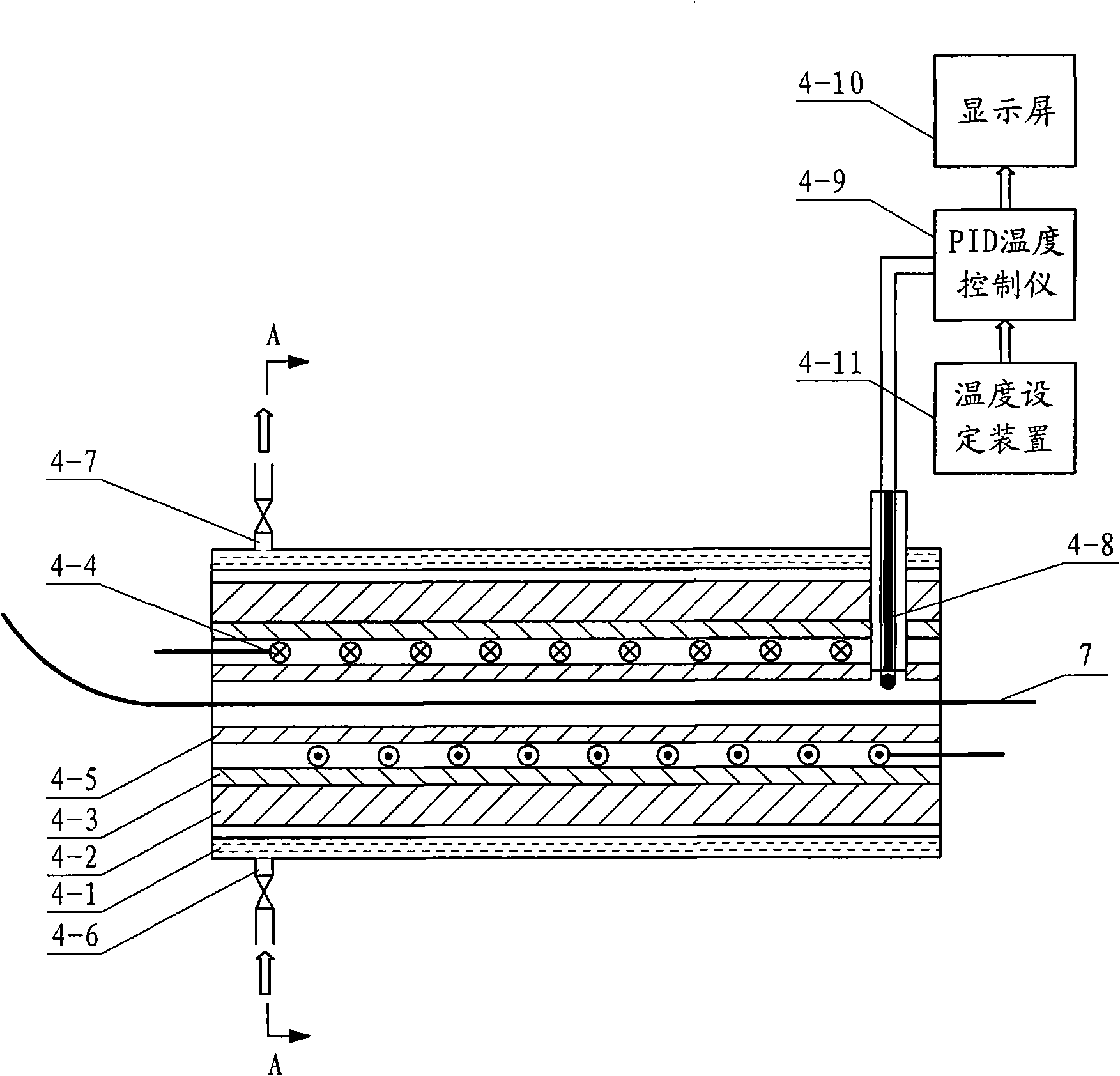

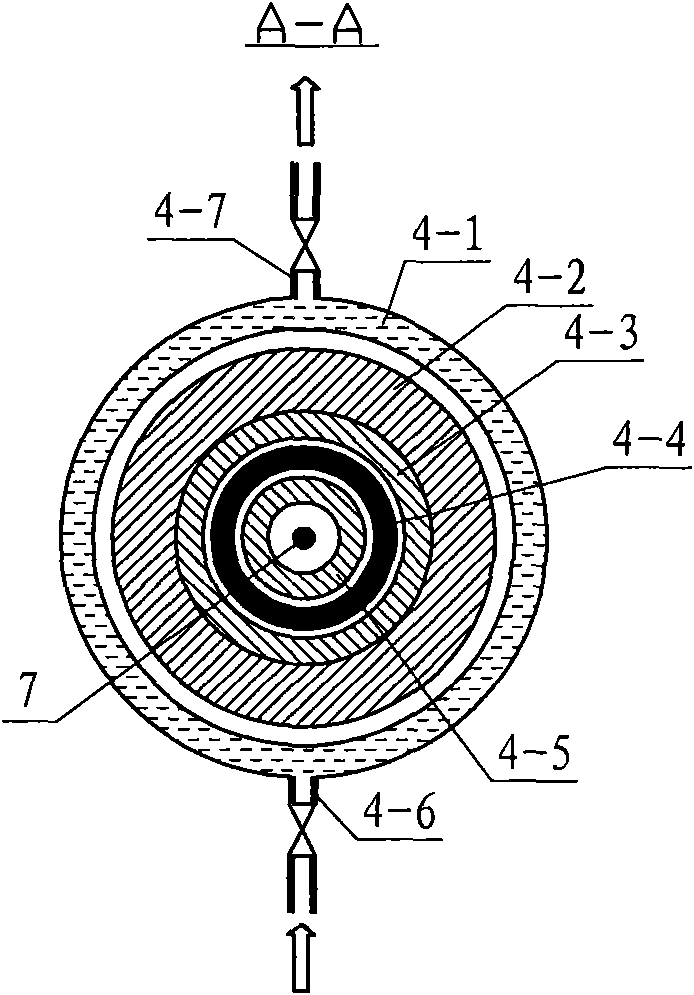

[0009] Specific implementation mode one: the following combination Figure 1 to Figure 3 To illustrate this embodiment, the preheating welding wire temperature control resistance sleeve 4 in this embodiment includes a cooling water jacket 4-1, a mica layer 4-2, an outer ceramic tube 4-3, a heating wire 4-4, and an inner ceramic tube 4- 5. An electric heating wire 4-4 is arranged between the water inlet pipe 4-6 and the water outlet pipe 4-7, the inner ceramic pipe 4-5 and the outer ceramic pipe 4-3, and the electric heating wire 4-4 is wound on the inner ceramic pipe 4-5, the outer surface of the outer ceramic tube 4-3 is provided with a mica layer 4-2, and the outer surface of the mica layer 4-2 is provided with a cylindrical cooling water jacket 4-1, cooling water jacket 4 The outer wall of -1 is provided with a water inlet pipe 4-6 and an outlet pipe 4-7 communicating with the outside world, which are used to enter and exit circulating cooling water.

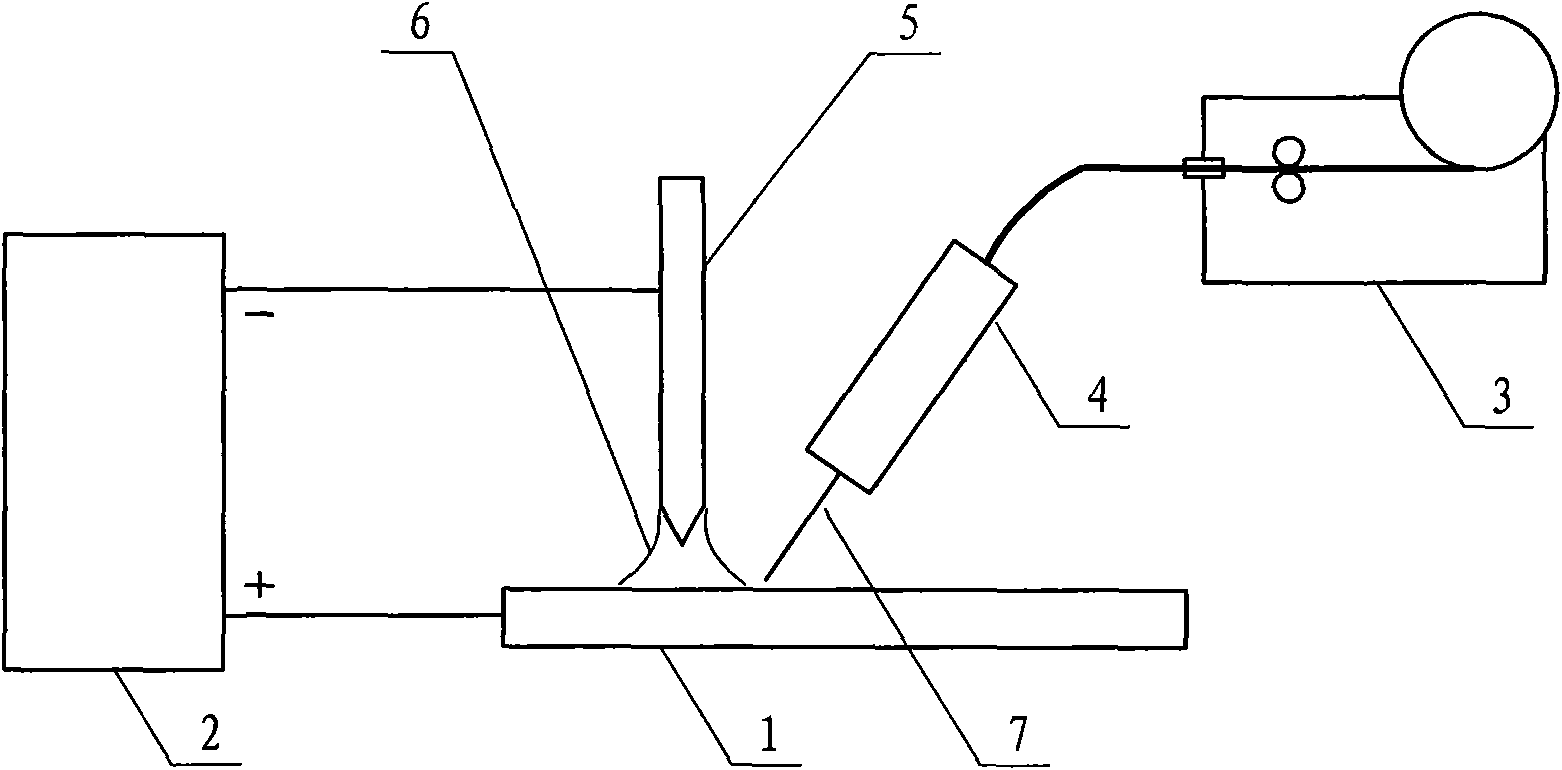

[0010] The TIG weldi...

specific Embodiment approach 2

[0014] Specific embodiment two: the difference between this embodiment and embodiment one is that it also includes a thermocouple 4-8 and a PID temperature controller 4-9, and the thermocouple 4-8 runs through the cooling water jacket 4-1 and the mica layer 4-2. The outer ceramic tube 4-3 and the inner ceramic tube 4-5, the temperature measuring end of the thermocouple 4-8 protrudes from the inner wall of the inner ceramic tube 4-5, and the cold end of the thermocouple 4-8 passes through the compensation The wires are connected to the PID temperature controller 4-9, and other components and connections are the same as those in Embodiment 1.

[0015] The thermocouple 4-8 monitors the temperature of the welding wire 7 passing through the cavity of the inner layer ceramic tube 4-5, and feeds back to the PID temperature controller 4-9.

[0016] The temperature control range of the PID temperature controller 4-9 is 50-400°C, and the control accuracy is ±5°C, that is, the temperatur...

specific Embodiment approach 3

[0017] Specific embodiment three: the difference between this embodiment and embodiment two is that it also includes a display screen 4-10 for displaying the temperature monitored by the thermocouple 4-8 and a temperature setting device for setting the temperature 4-11, the output end of the temperature setting device 4-11 is connected to the input end of the PID temperature controller 4-9, the output end of the PID temperature controller 4-9 is connected to the display screen 4-10, other components and connection relations It is the same as Embodiment 2.

[0018] The present invention controls the preheating temperature of the welding wire 7 through the PID temperature controller 4-9, and sets the preheating temperature of the welding wire 7 through the temperature setting device 4-11; the temperature of the welding wire 7 is controlled by the thermocouple 4-8 The temperature measuring terminal monitors it and feeds it back to the PID temperature controller 4-9, which is disp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com