Miniature pure oxygen combustion gas turbine generator

A technology for gas turbine generators and generators, applied to gas turbine devices, engine components, machines/engines, etc., can solve the problems of not greatly improving conversion efficiency, increasing power consumption, ecological damage, etc., and achieve heat recovery Improvement of quality, elimination of power consumption, and improvement of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

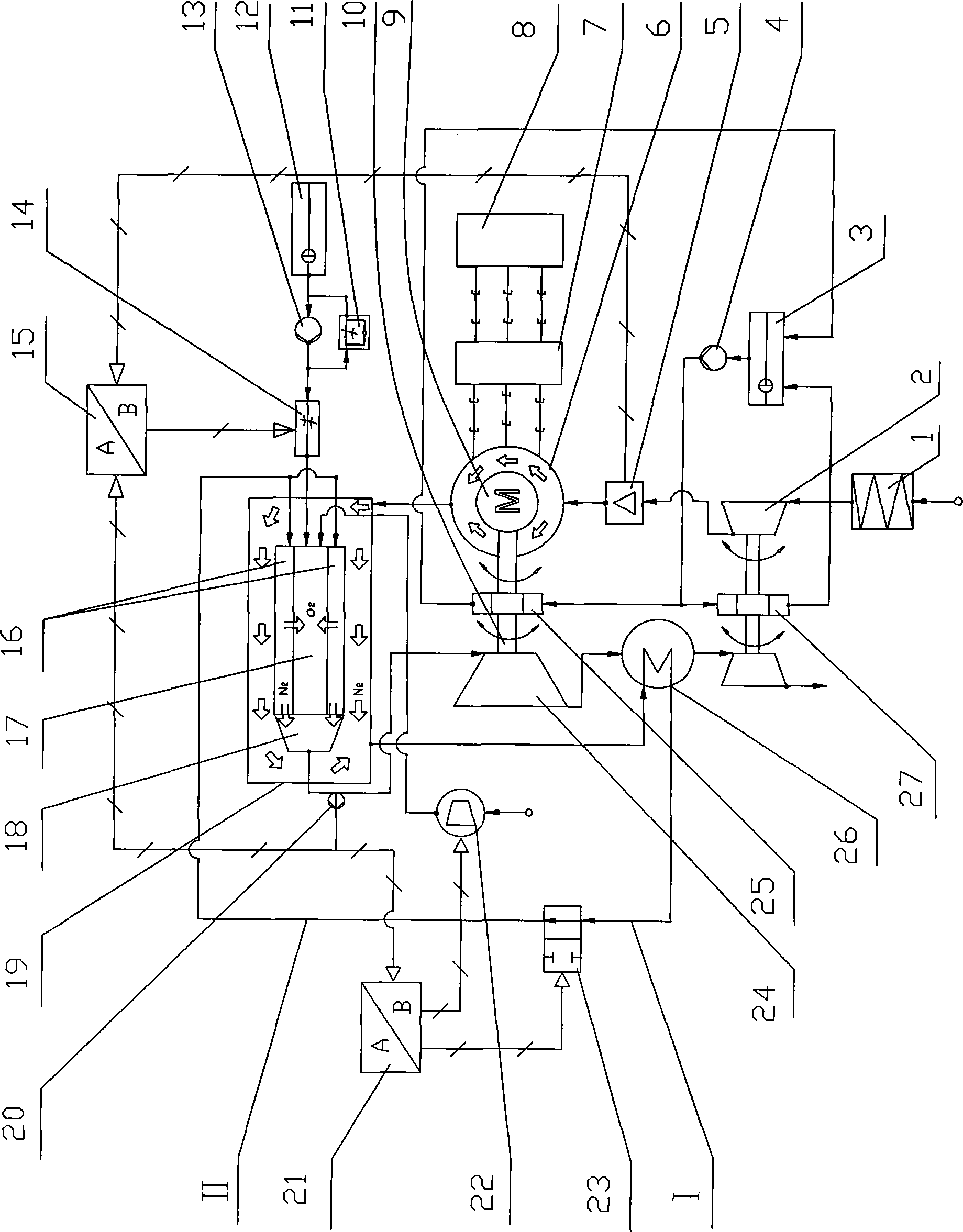

[0019] Such as figure 1 As shown, the gas turbine generator described in this embodiment has seven systems: a fuel supply system, a pure oxygen supply system, a combustion work system, a control system, a power generation system, an energy recovery system and a lubricating oil system. The specific connection relationship is as follows:

[0020] The fuel supply system consists of a fuel tank 12 , a fuel delivery pump 13 and a controllable flow valve 14 in sequence from outside (outside) to inside (inside). The output end of the controllable flow valve 14 is directly connected to the input end of the combustion chamber 17 . In order for the controllable flow valve 14 to control the actual fuel injection volume to be less than the rated output flow rate of the fuel delivery pump 13, excess fuel can be returned to the inlet port of the fuel delivery pump 13 to prevent the overpressure of the fuel delivery pump damage, in this example, an overflow valve 11 is connected in parallel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com