Ink-jet driving circuit with preheat function

A driving circuit and inkjet technology, applied in electrical components, electronic switches, printing, etc., can solve problems affecting printing quality, insufficient preheating temperature of inkjet head, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Some typical embodiments embodying the features and advantages of the present invention will be described in detail in the description in the following paragraphs. It should be understood that the invention is capable of various changes in different aspects without departing from the scope of the invention, and that the description and illustrations therein are illustrative in nature and not limiting. this invention.

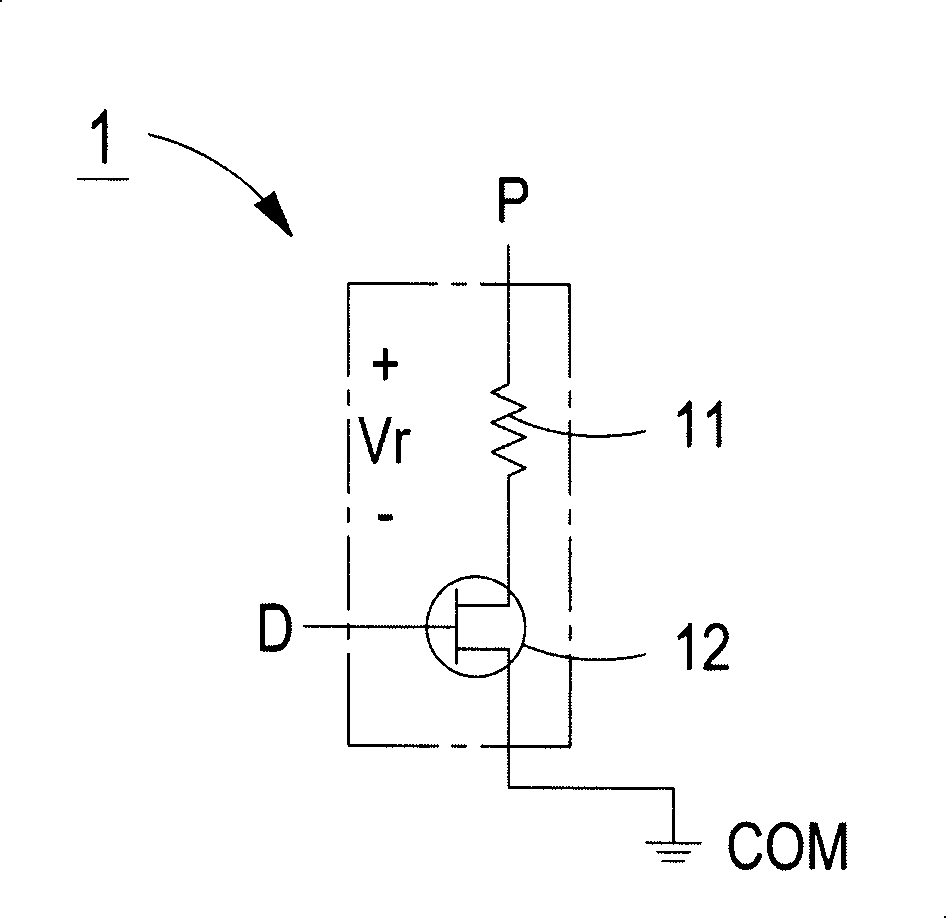

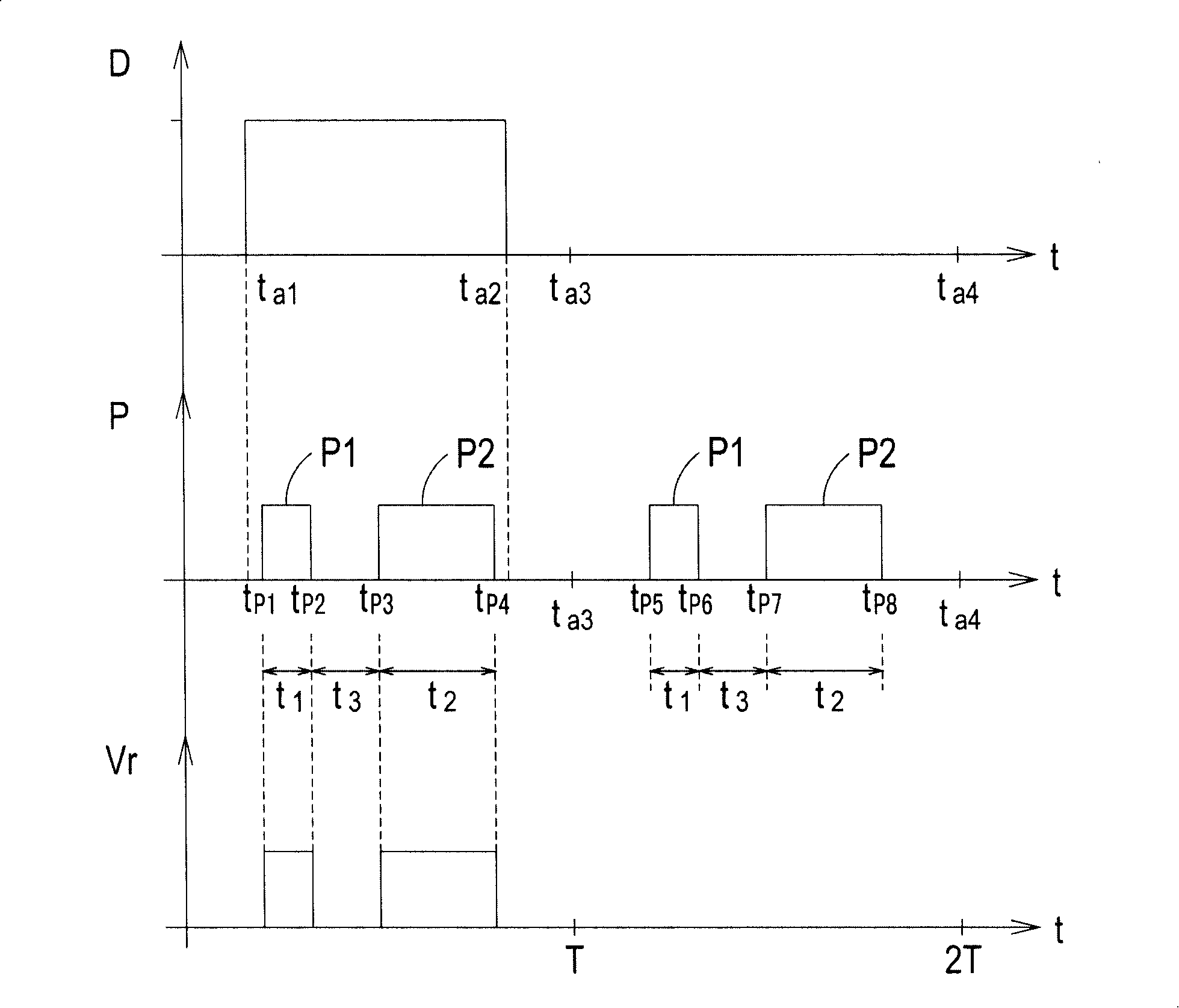

[0029] Generally speaking, the heating chip arranged inside the structure of the inkjet head has a plurality of inkjet holes arranged on the heating chip, and each inkjet hole has an inkjet drive circuit to control the inkjet Whether the hole is ink-jet or not, because the inkjet head has multiple ink-jet holes that need to be controlled, so there must be multiple inkjet drive circuits on the heating chip. The following will take a single inkjet drive circuit as an example to illustrate, but not This is the limit.

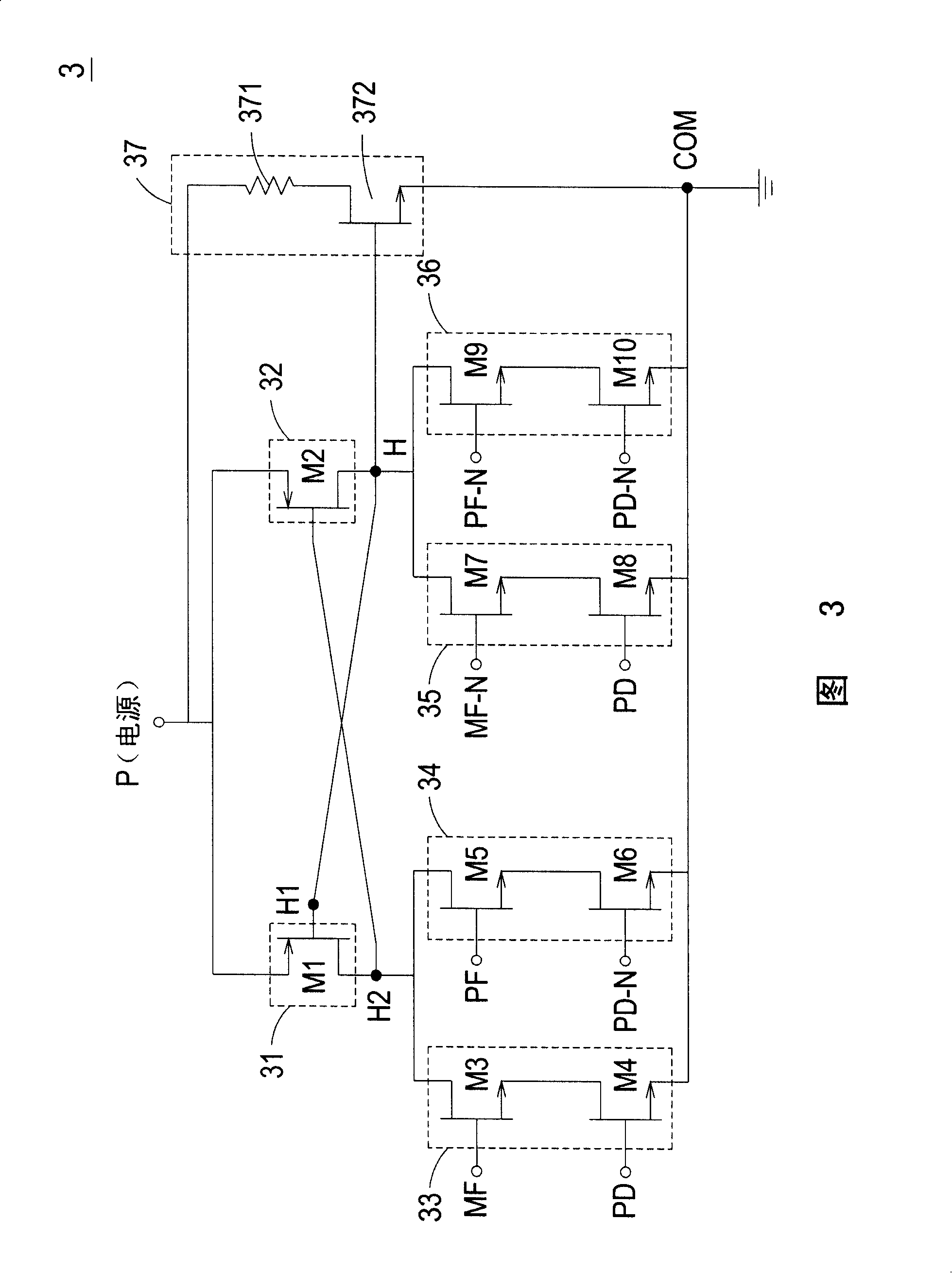

[0030] Please refer to FIG. 3 , which...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com