Device, system and process method for preparing olefin through reaction of carbon dioxide and light alkane

A technology of carbon dioxide and low-carbon alkanes, applied in the field of conversion and utilization of carbon dioxide, can solve the problems of heat transfer limitation, large output, waste of energy and raw materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

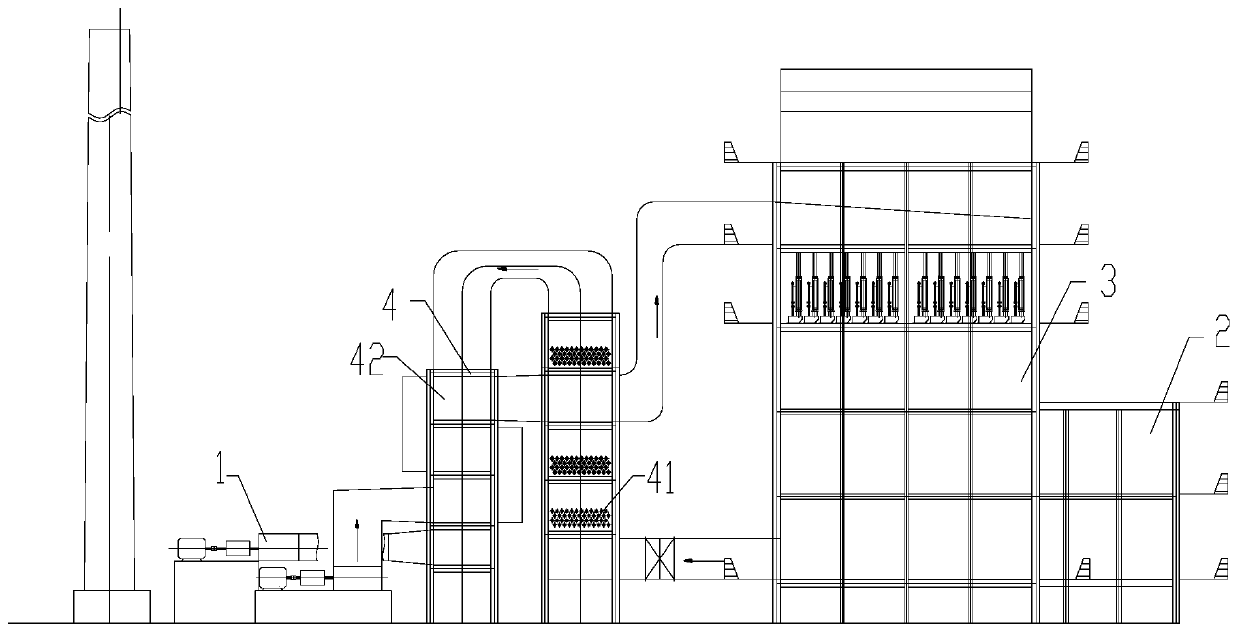

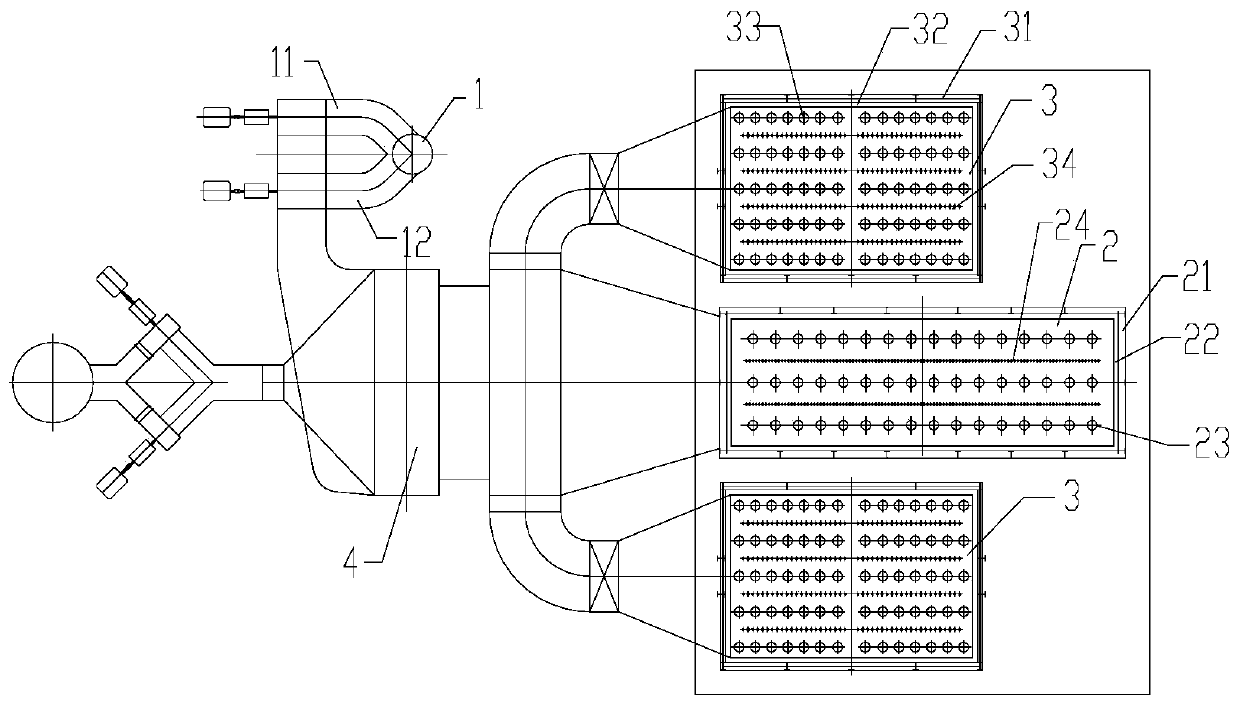

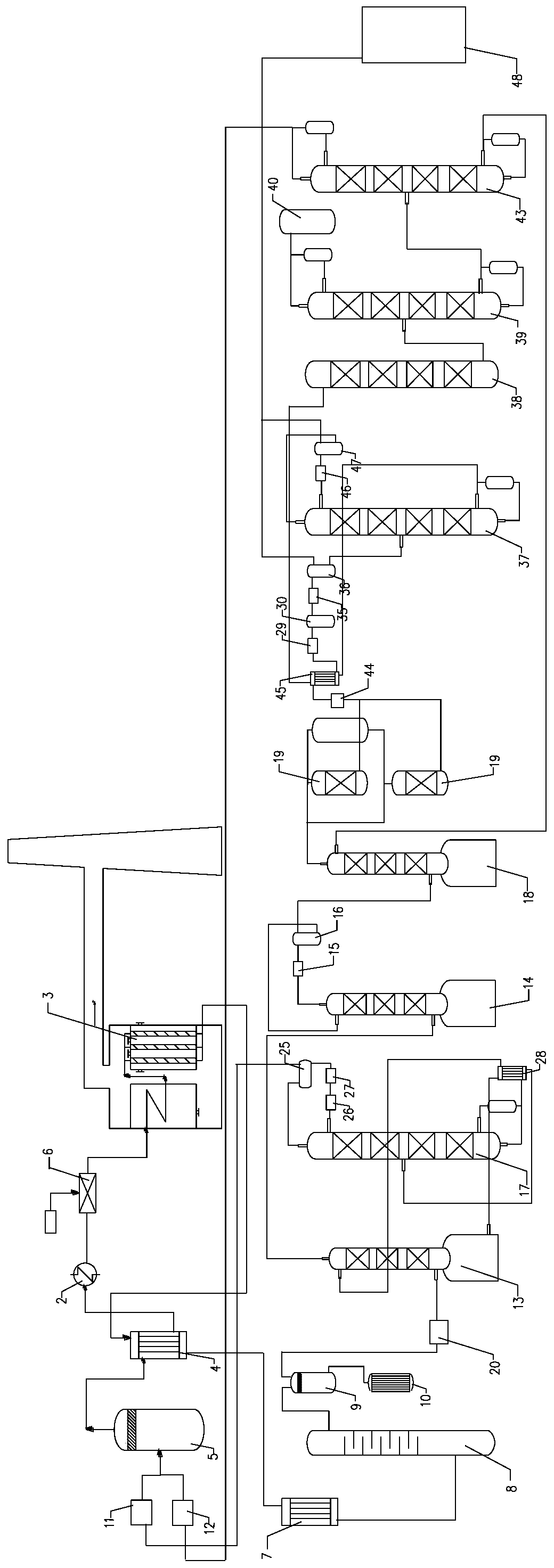

[0075] Such as figure 1 , 2 As shown, the device for preparing olefins by reacting carbon dioxide and light alkanes in this embodiment includes a feed port 1, a feed preheating furnace 2 and a reaction furnace 3, and a feed port 1 and a feed preheating furnace 2 The inlet of the feed preheating furnace 2 is connected with the inlet of the reactor 3, the inlet of the reactor 3 is provided with a first gas distributor; the reactor 3 includes a reactor shell 31, and the reactor shell 31 is provided Multi-layer heating zone, the heating zone is surrounded by the first heating wall 32; in each heating zone there are multiple rows of reaction tubes 33 in parallel, one end of each reaction tube 33 is connected to the first gas distributor, and the other end is connected to the outlet of the reaction tube Connection; a first heating nozzle 34 is set between the reaction tubes 33.

[0076] Carbon dioxide and low-carbon alkanes are fed through the feed port 1, enter the feed preheating fur...

Embodiment 2

[0081] The device for preparing olefins by the reaction of carbon dioxide and light alkanes in this embodiment is further improved on the basis of the device for preparing olefins by the reaction of carbon dioxide and light alkanes in Example 1. The structure of the rest of the device is the same as that of Example 1. The structure is the same, but the difference is that the device for preparing olefins by reacting carbon dioxide and low-carbon alkanes in this embodiment also includes a feeding mixer 6 suitable for mixing carbon dioxide, low-carbon alkanes and steam, and the feeding mixer 6 is provided with steam The inlet, the inlet of the feeding mixer 6 is connected with the outlet of the feeding preheating furnace 2, and the outlet of the feeding mixer 6 is connected with the inlet of the reactor 3. The mixed gas of carbon dioxide and low-carbon alkanes preheated by the feed preheating furnace 2 enters the feed mixer 6, and is mixed with the steam injected from the steam inl...

Embodiment 3

[0117] The process method for preparing ethylene by the reaction of carbon dioxide and ethane in this embodiment is the same as that in Embodiment 2. The difference is that in this embodiment, in step S1, the molar ratio of carbon dioxide to ethane is 1.2:1 , The reaction temperature is 700℃, and the ethane space velocity is 1300h -1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com