A vacuum preheating electron beam welding method for large thickness workpieces

An electron beam welding, large-thickness technology, applied in electron beam welding equipment, welding equipment, manufacturing tools, etc., can solve the problems of difficult to control preheating temperature, high cold crack susceptibility, and decreased plastic toughness in the weld area. The effect of avoiding hardened structure, controllable preheating temperature and reducing cooling rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below with reference to the accompanying drawings and specific embodiments.

[0020] The invention provides a vacuum preheating electron beam welding method for workpieces with large thickness. The workpieces to be welded are high-strength alloys with a thickness of not less than 100 mm. The invention uses a preheating device to preheat the workpieces to be welded to a high temperature under vacuum conditions. state (50-1000℃), and then implement vacuum electron beam welding to avoid the tendency of cold cracking after welding of high-strength alloys (titanium, steel, etc.), and obtain welded joints with better matching of strength and toughness, and excellent comprehensive mechanical properties.

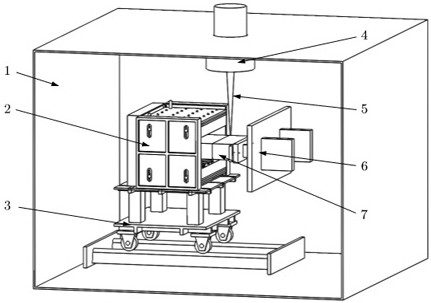

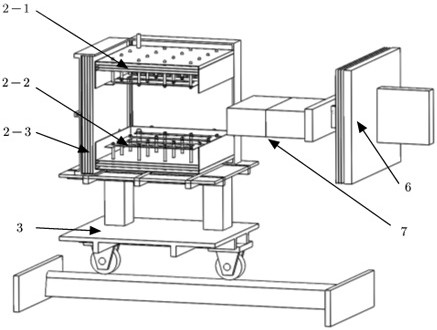

[0021] Figure 1-2 Shown is a vacuum preheating welding device used in the present invention, including: a vacuum chamber 1, a preheating device 2, a mobile platform 3, an electron beam welding machine 4, an electron g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com