Pre-heating and heating device of high-temperature molten salt storage tank

A technology for high-temperature molten salt storage tanks and heating devices, applied in electric heating devices, ohmic resistance heating, tank cars, etc., can solve problems such as leakage at the weld seam of the connection pipe, large stress at the bottom of the tank wall of large-capacity high-temperature storage tanks, and huge losses. Achieve the effect of high preheating efficiency, high preheating precision, high efficiency and uniform heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

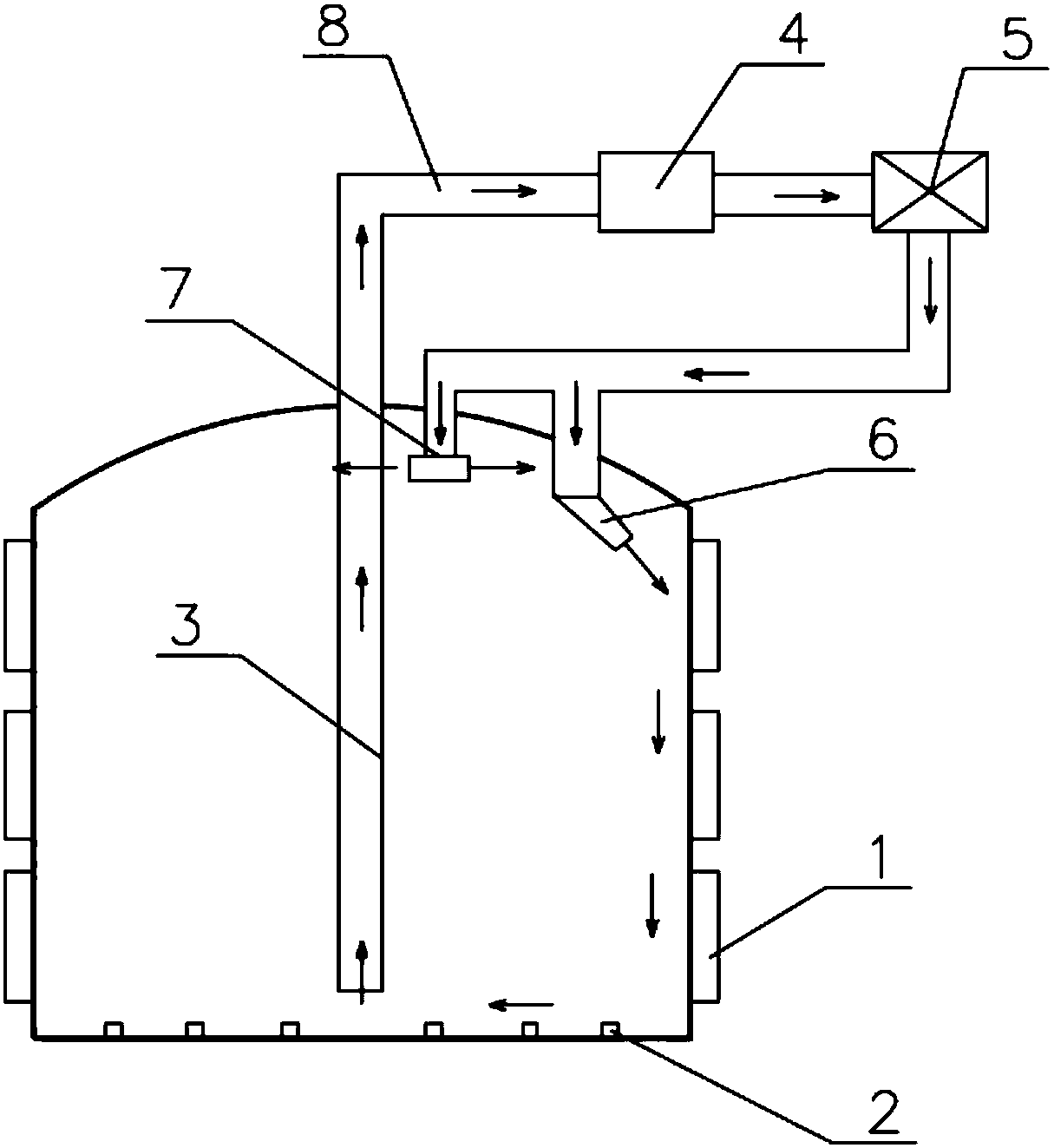

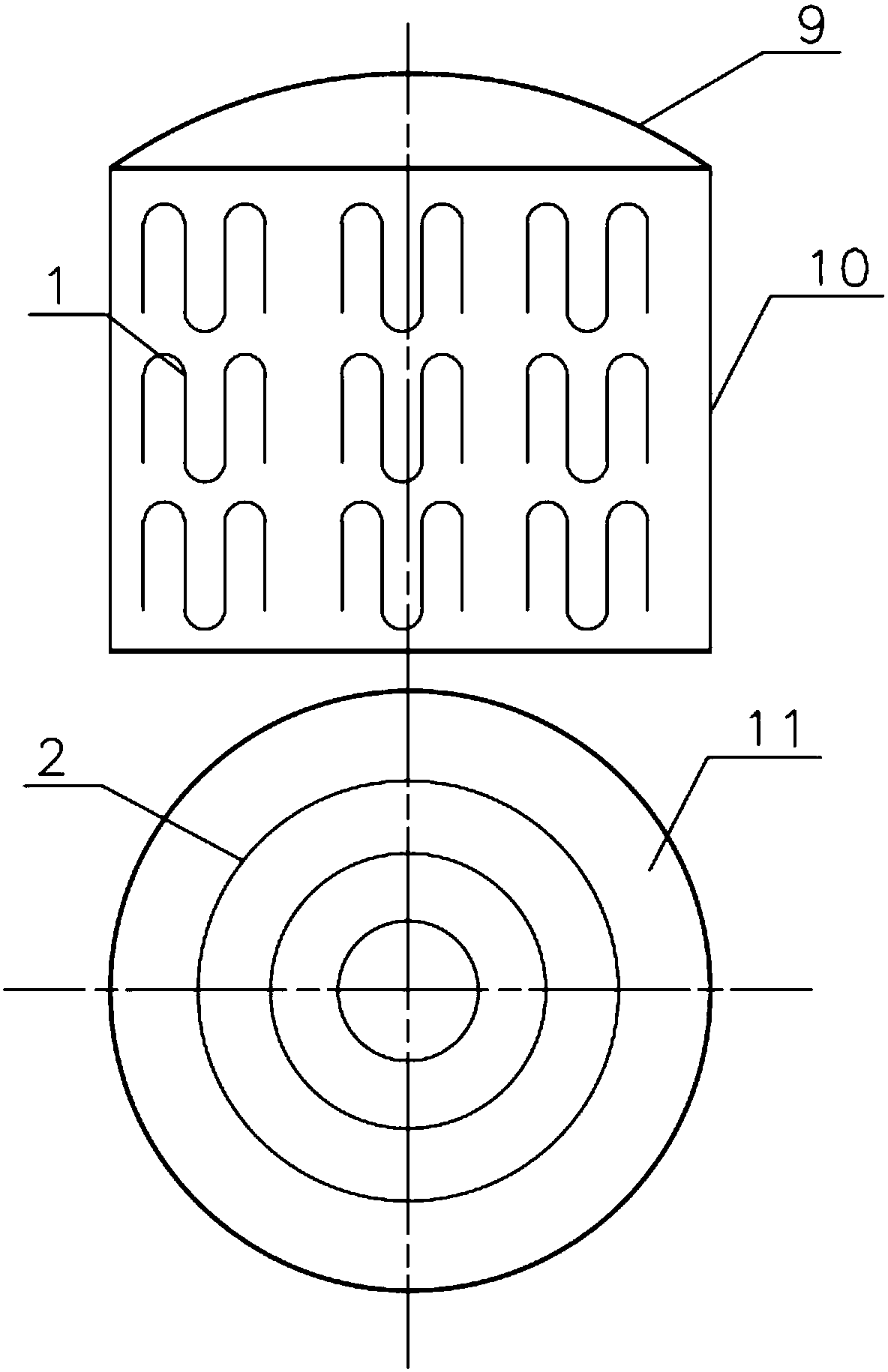

[0023] Such as figure 1 As shown, a preheating and heating device for a high-temperature molten salt storage tank of the present invention includes electric heat tracing for tank wall 1, electric heat tracing for tank bottom 2, air collecting pipe 3, circulating fan 4, damper regulator 5, fixed screw The nozzle 6, the rotary nozzle 7 and the air duct 8 are connected by welding or flanges. Tank wall electric heat tracing 1 is arranged according to the thickness and height of the tank wall, and most of them are arranged in the middle and lower part of the tank wall. Electric heat tracing 2 at the bottom of the tank is arranged evenly along the radial and circumferential directions. The air collecting pipe 3 is arranged on the top of the tank and inserted into the tank to the bottom of the tank. Through the air duct 8, the air collecting pipe 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com