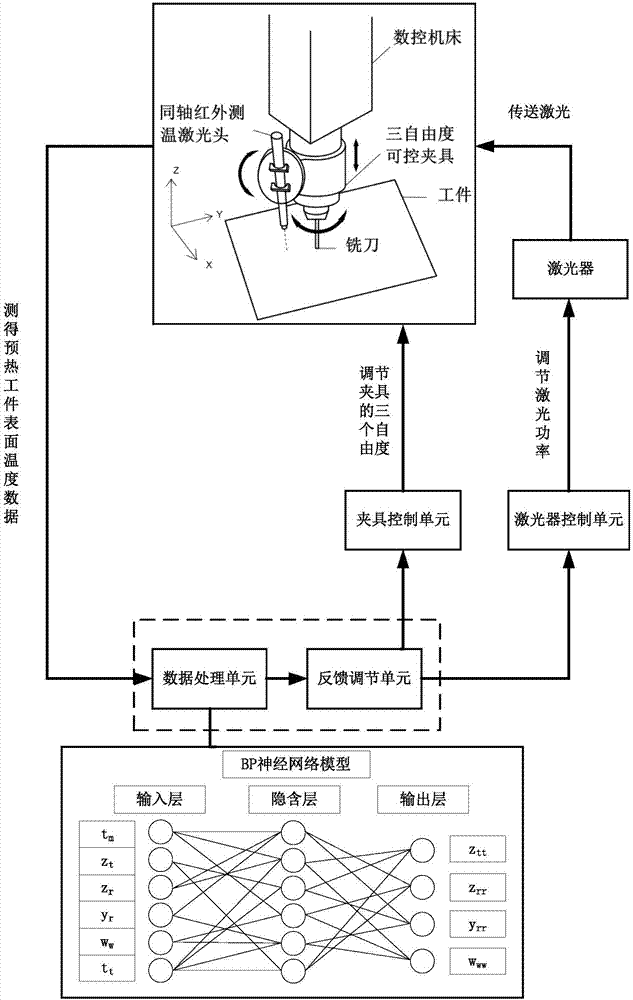

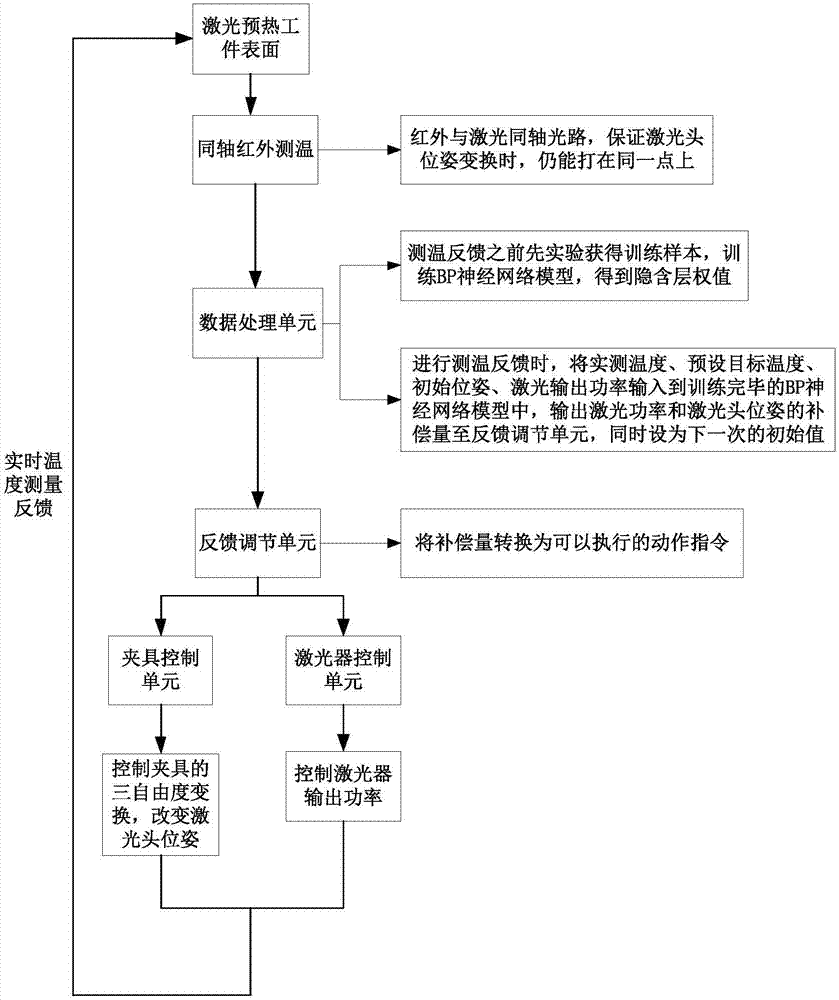

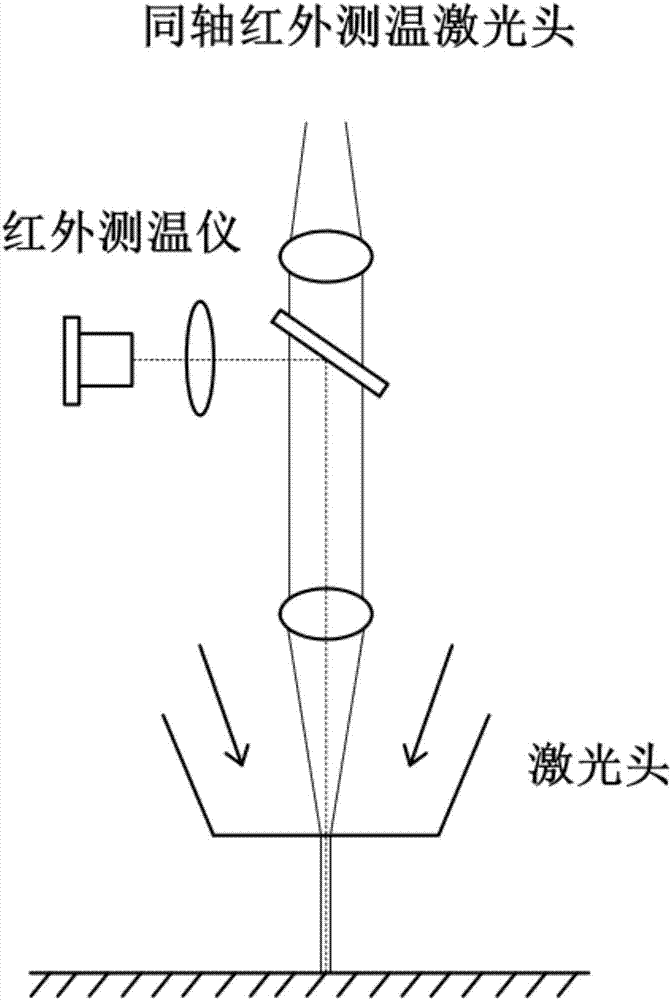

Laser preheating machining system integrated with temperature field real-time measuring and feedback control functions

A real-time measurement and feedback control technology, used in metal processing, manufacturing tools, metal processing equipment, etc., can solve problems such as position state influence, achieve precise laser preheating temperature control, improve preheating efficiency, and shorten the preheating cycle. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0040] Example: silicon nitride ceramic material workpiece

[0041] Workpiece cutting depth: 0.2mm

[0042] Spindle speed: 2000rpm

[0043] Feed speed: 12mm / min

[0044] Laser power: 300W

[0045] Spot diameter: 3mm

[0046] In this application example, since each processing point on the surface of the workpiece is at the same temperature, the surface roughness and residual stress can be small enough, the workpiece can be preheated and cut smoothly, and the residual stress on the surface after cutting is small. It is measured that the cutting hardening layer is small, and the surface roughness is small and uniform as measured by the surface topography instrument. Therefore, a laser preheating processing system with integrated temperature field real-time measurement and feedback control functions proposed by the present invention can achieve a constant temperature field and overcome the shortcomings of material properties and internal crystal phase changes caused by tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com