Tungsten inert gas welding (TIG) welding torch and welding device for manufacturing multi-wire common molten pool electric wire additives, and additive manufacturing method

A technology of additive manufacturing and eutectic pool, applied in arc welding equipment, manufacturing tools, welding equipment, etc., can solve the problems of stress cracking, long residence time, and low deposition efficiency at the deposition site.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with accompanying drawing of description and embodiment:

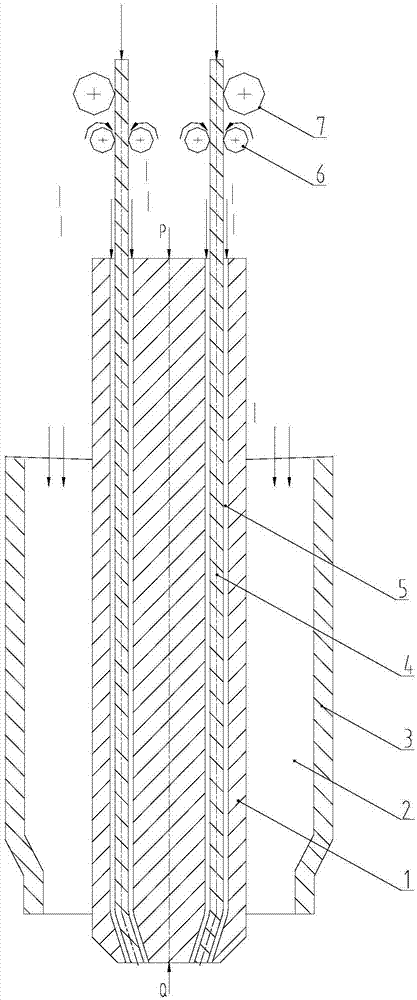

[0017] Such as figure 1 As shown, the multi-wire eutectic pool arc additive manufacturing TIG welding gun includes a gun body, the front end of the gun body is provided with a porcelain nozzle 3, and the inside of the gun body has a cavity, and a hollow tungsten electrode 1 is inserted through the cavity so that the hollow tungsten electrode The front end of the gun protrudes from the port of the porcelain nozzle, and a protective air chamber 2 is formed between the inner wall of the gun and the hollow tungsten pole; there are four wire feeding channels axially arranged in the hollow tungsten pole, and of course it can be set to more than four or Less than four and more than one; the other end of the gun body away from the porcelain nozzle is provided with an air inlet connected to the shielding gas source, and the shielding gas source is also ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com