Steam sterilizing device of rare precious medicinal material

A technology of steam sterilization and cooling chamber, which is applied in the field of steam sterilization devices for rare and precious medicinal materials, which can solve the problems of affecting the medicinal value and damage to the materials to be sterilized, and achieve the goals of reducing loss, low cost and good cooling effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

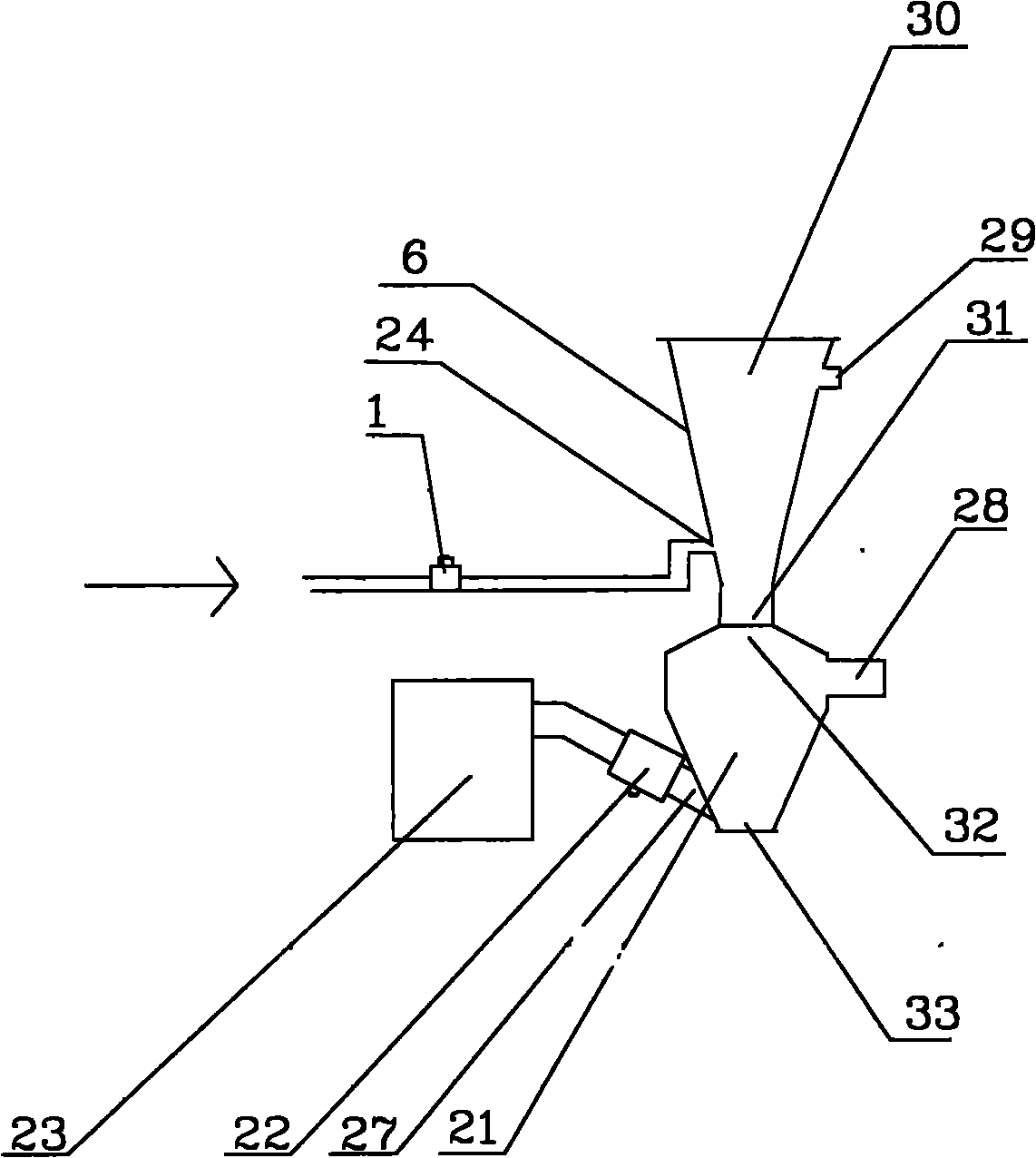

[0034] figure 1 A schematic diagram of the steam sterilization device according to the present invention is provided, and it can be seen from the figure that the steam sterilization device includes a sterilization chamber 6 and a cooling chamber 21; a sterilization chamber is arranged on the sterilization chamber 6 The feed inlet 30 and the sterilization chamber discharge port 31 are also provided with a hot air inlet 24 on the sterilization chamber 6, and the superheated sterilization steam enters the sterilization chamber 6 through the pulse control valve 1 through the hot air inlet 24 Inside. A gas discharge port 29 is also provided on the sterilization chamber 6, and the gas discharge port 29 is arranged outside the sterilization chamber 6. In this embodiment, it is located on the upper part of the sterilization chamber 6, through which the gas The switch of the discharge port 29 realizes the discharge of hot steam and hot air inside the sterilization chamber 6 .

[0035...

Embodiment 2

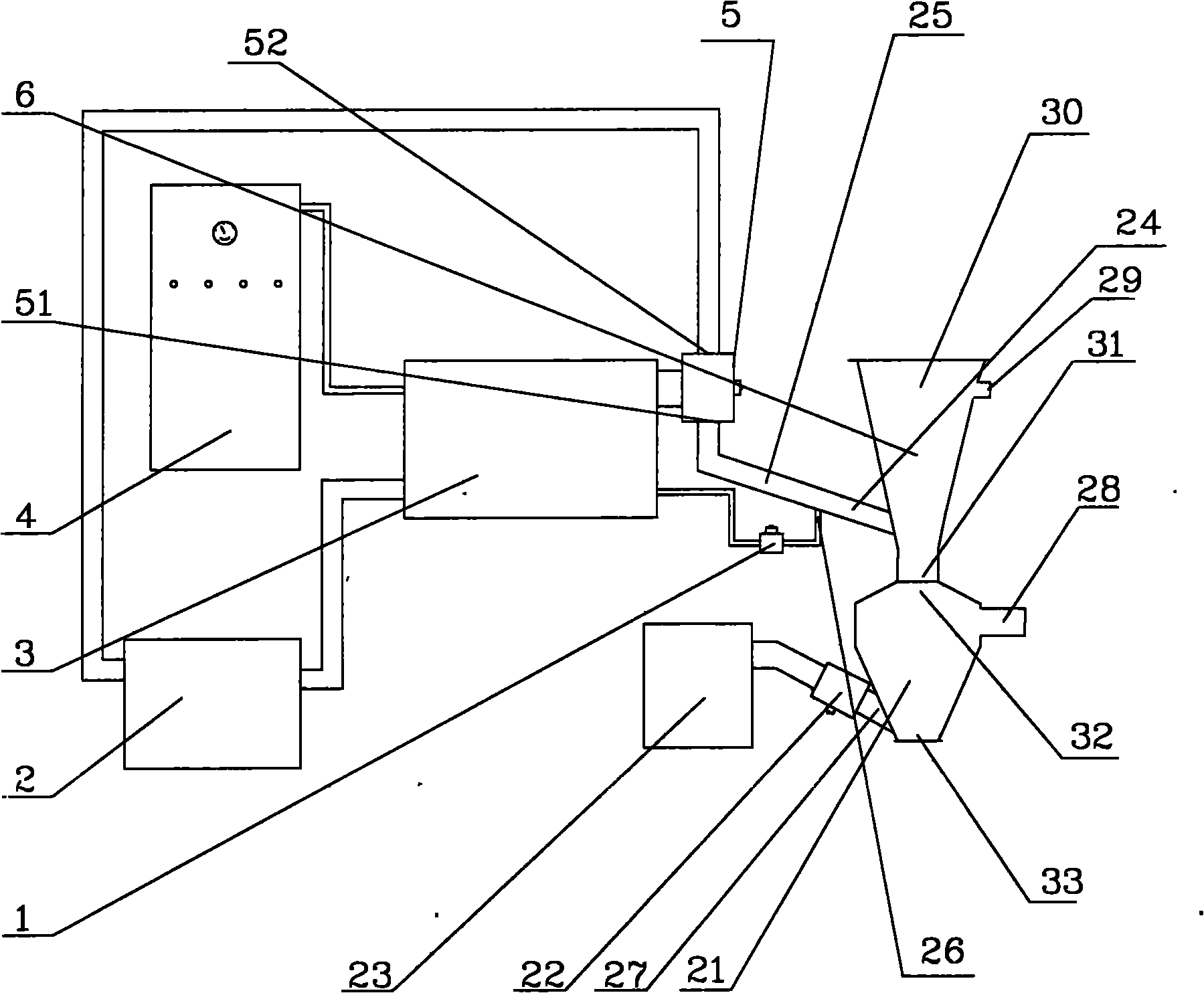

[0038] The steam sterilizer described in this embodiment is as figure 2 As shown, the hot air inlet 24 is also provided with a first branch air inlet 25 and a second branch air inlet 26, and the first branch air inlet 25 communicates with the heat through the first passage 51 of the three-way control valve 5. The heat exchanger 3 is connected, and the second branch air inlet 26 is connected with the heat exchanger 3 through the pulse control valve 1, and the heat exchanger 3 is connected with the hot air induced draft fan 2 and the steam generator 4, and the three-way control valve The second passage 52 communicates with the hot air induced fan 2 .

[0039] When the steam sterilizer in this embodiment is working, it is first necessary to open the gas discharge port 29, and at the same time open the hot air induced draft fan 2 and the first passage 51 of the three-way control valve, through which the hot air induced draft fan 2 can exchange heat The device 3 and the sterilizi...

Embodiment 3

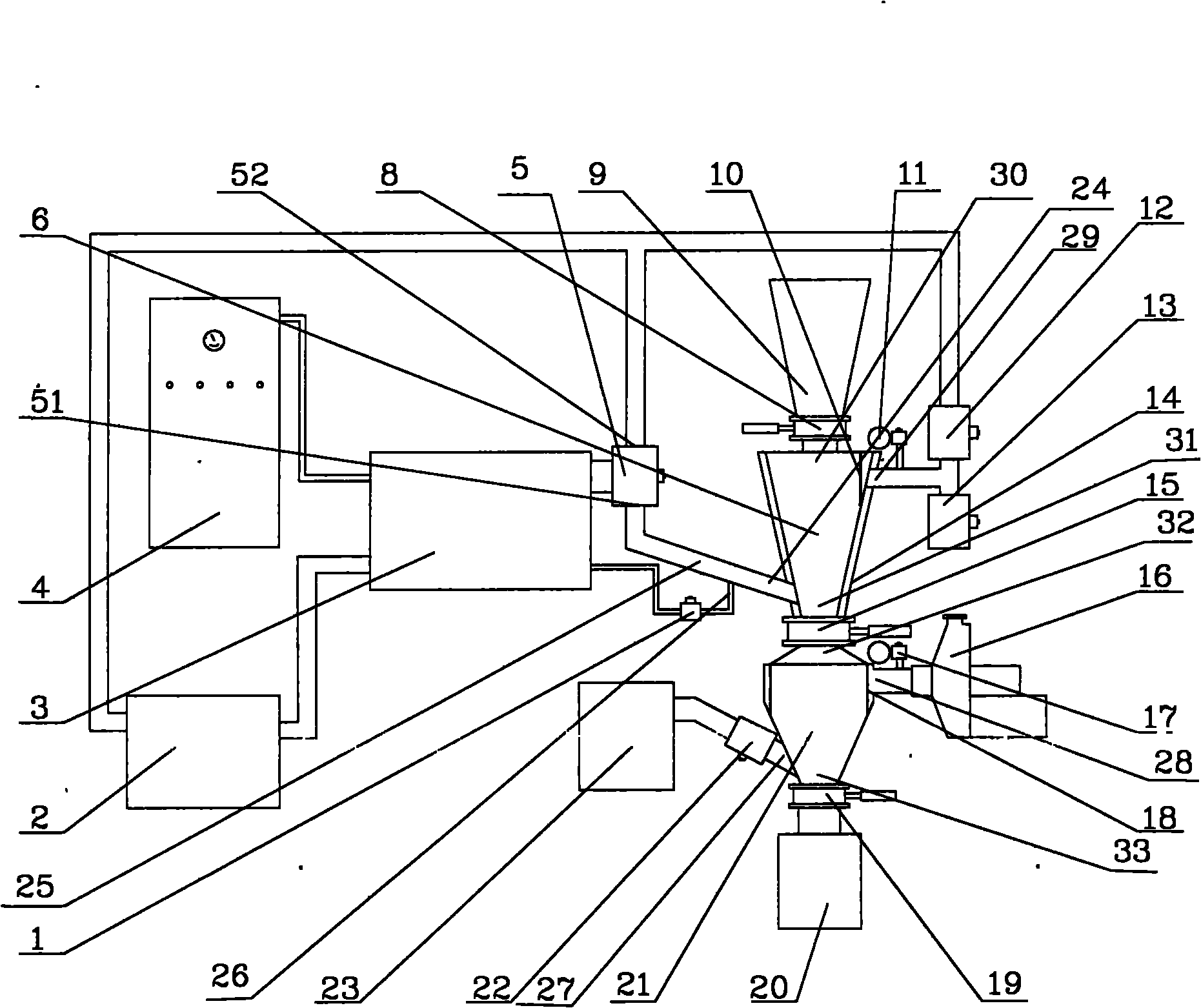

[0042] The steam sterilizer described in this embodiment is as image 3 As shown, it is provided with a sterilization chamber shell 14 that forms an interlayer with the sterilization chamber 6 on the sterilization chamber 6, and fills the heat preservation medium in the interlayer, thereby reducing the sterilization process of the sterilization chamber 6 as much as possible. Neutralize the external energy exchange, thereby reducing the loss of high temperature and reducing energy consumption. In addition, a feed hopper 9 is further provided at the feed port 30 of the sterilization chamber, and the feed hopper 9 and the feed port 30 of the sterilization chamber are connected through a feed port control valve 8 to facilitate the addition of materials. Similarly, a control valve 15 for the discharge port of the sterilized chamber can be set between the discharge port 31 of the sterilized chamber and the feed port 32 of the cooling chamber to control the transfer of the sterilized...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com