Low-temperature preheating system for battery pack of electric vehicle and control method of low-temperature preheating system

An electric vehicle and battery management system technology, applied in the field of electric vehicle battery pack preheating, can solve the problems of battery heating, poor battery pack balance, and high failure rate, and achieve the effects of simple control, uniform preheating, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

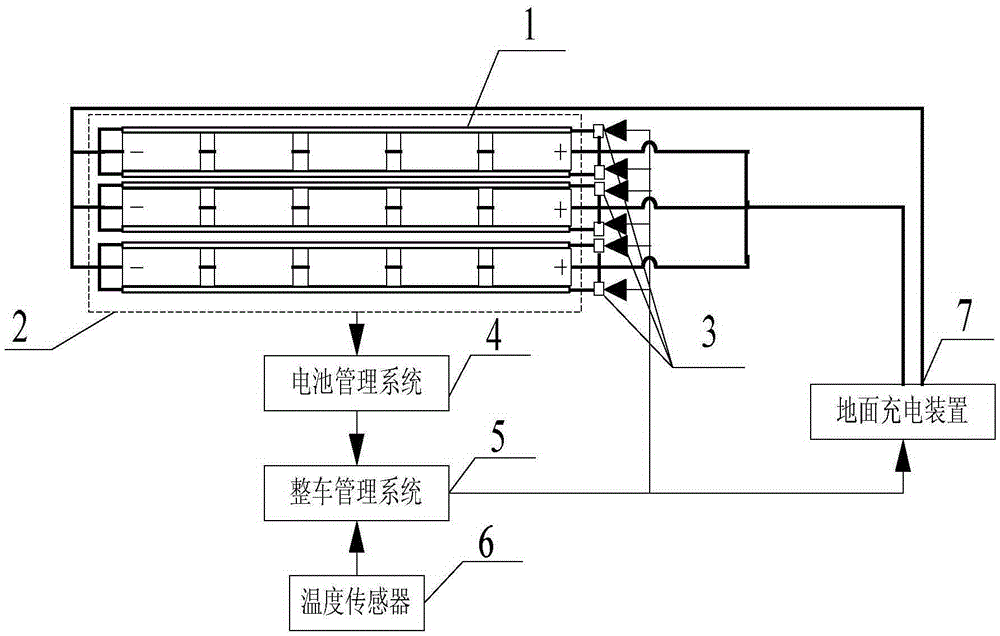

[0021] Specific implementation mode 1. Combination figure 1 Describe this embodiment, a low-temperature preheating system for an electric vehicle battery pack described in this embodiment, the system includes an electrothermal film 1, a relay set 3, a battery management system 4, a vehicle management system 5, a temperature sensor 6 and ground charging device 7;

[0022] An electrothermal film 1 is pasted on the outside of the outermost battery cells of the battery pack 2 and between every two adjacent rows of battery cells.

[0023] The battery management system 4 is used to collect the remaining power information of the battery pack 2, the remaining power signal output terminal of the battery pack of the battery management system 4 is connected to the battery pack remaining power signal input terminal of the vehicle management system 5, and the relay of the vehicle management system 5 The switch control signal output terminal is connected to the switch control signal input ...

specific Embodiment approach 2

[0026] Embodiment 2. This embodiment is a control method for the low-temperature preheating system of an electric vehicle battery pack described in Embodiment 1. The specific steps of the method are:

[0027] Step 1, using the temperature sensor 6 to collect the temperature T1 in the battery pack 2;

[0028] Step 2. The vehicle management system 5 judges whether the temperature T1 is greater than the target temperature T according to the temperature T1 in the battery pack 2 obtained in the step 1. g , if T1>T g , then go to step ten; otherwise go to step three; where, T g is a positive number;

[0029] Step 3. Use the battery management system 4 to collect the remaining power of the battery pack 2. The vehicle management system 5 judges whether the remaining power of the battery pack 2 is greater than the battery warm-up power threshold Q1. If the judgment result is yes, then perform step 4. If the judgment result is If no, go to step 7;

[0030] Step 4, the vehicle manage...

specific Embodiment approach 3

[0037] Specific Embodiment 3. This embodiment is a further description of the control method of the electric vehicle battery pack low-temperature preheating system described in Specific Embodiment 2. The temperature threshold T g is 10 degrees.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com