Large non-standard device thick-plate all-position welding method

A welding method and all-position technology, applied in the field of steel structure welding, can solve the problems of uneven stress and easy deformation of the weldment, and achieve the effect of stable structure, small overall deformation and good plasticity of the weldment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings.

[0019] The process flow for large thick plate welding is generally: welding procedure qualification → construction preparation → blanking, assembly → preheating → welding → visual inspection → hydrogen elimination after welding → non-destructive testing → annealing.

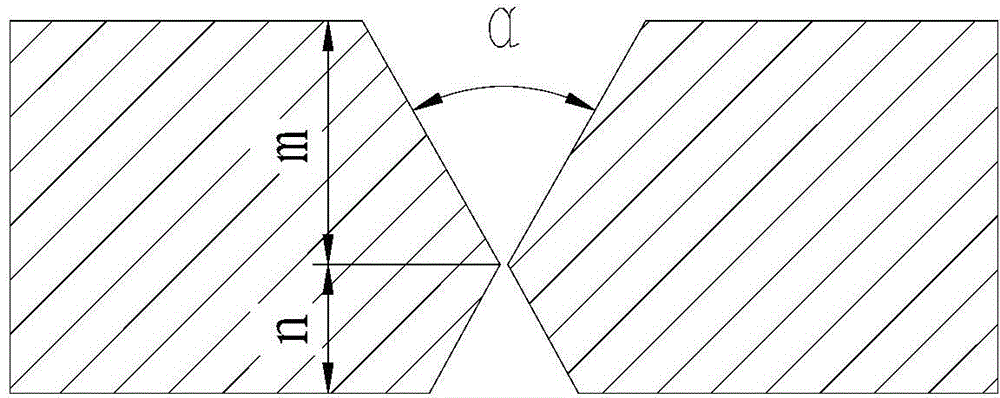

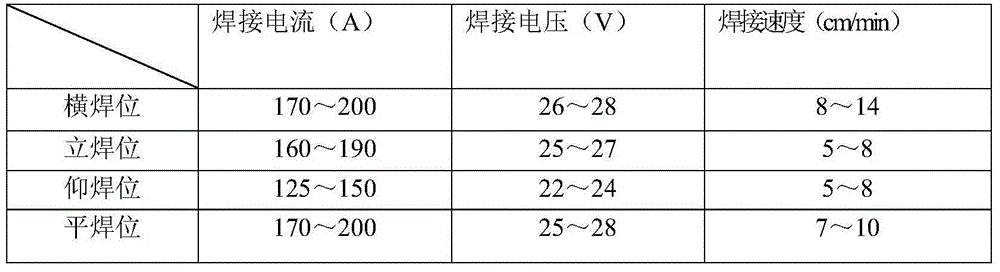

[0020] Welding process evaluation includes groove selection and welding parameter selection. The weld groove type of the present invention is selected according to HG20586-1998 standard DU36 and asymmetrical X-shaped groove. The asymmetrical X-shaped groove refers to two weldments. The groove on the side is asymmetrical, taking the plate thickness of 70mm as an example, such as figure 1 As mentioned above, a 9m edge planer and a semi-automatic oxyacetylene flame cutting machine are used for the groove. The specific size of the groove should be selected according to the thickness of the steel plate. The gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com