Plate warm electro-hydraulic high-speed impact-quasi static hydraulic composite forming device and plate forming method achieved by adopting device

A high-speed impact, composite forming technology, used in forming tools, metal processing equipment, manufacturing tools, etc., can solve problems such as uneven deformation, poor film bonding, difficult-to-form plates and complex parts forming, to prevent cracking and shorten forming. cycle, the effect of ensuring forming quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

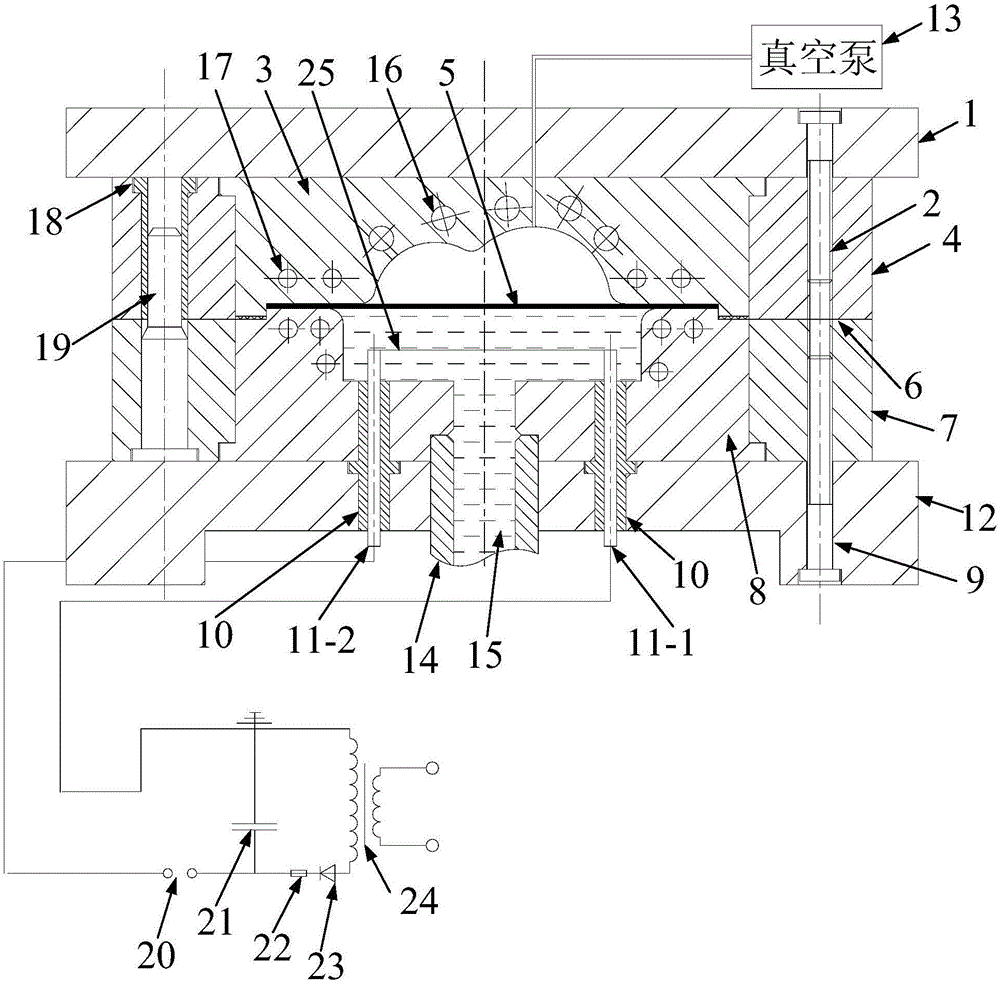

[0047] Specific implementation mode one: refer to Figure 1 to Figure 13 Describe this embodiment in detail. The plate warming electro-hydraulic high-speed impact-quasi-static hydraulic composite forming device described in this embodiment includes an electromagnetic forming system, a liquid filling device 14, an electro-hydraulic forming mold, a cooling device 16, and a heating device 17 and vacuum pump 13,

[0048] The electro-hydraulic forming mold includes an upper mold and a lower mold,

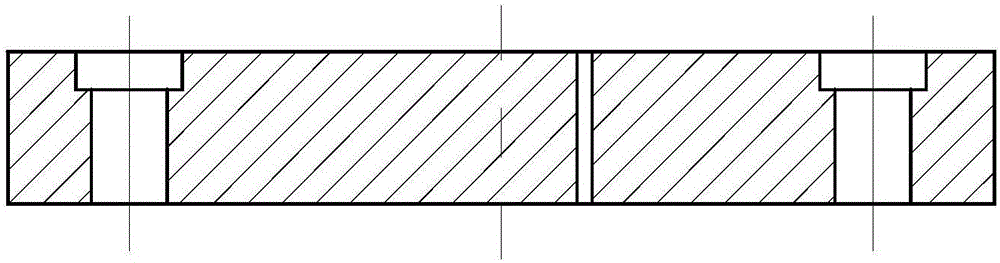

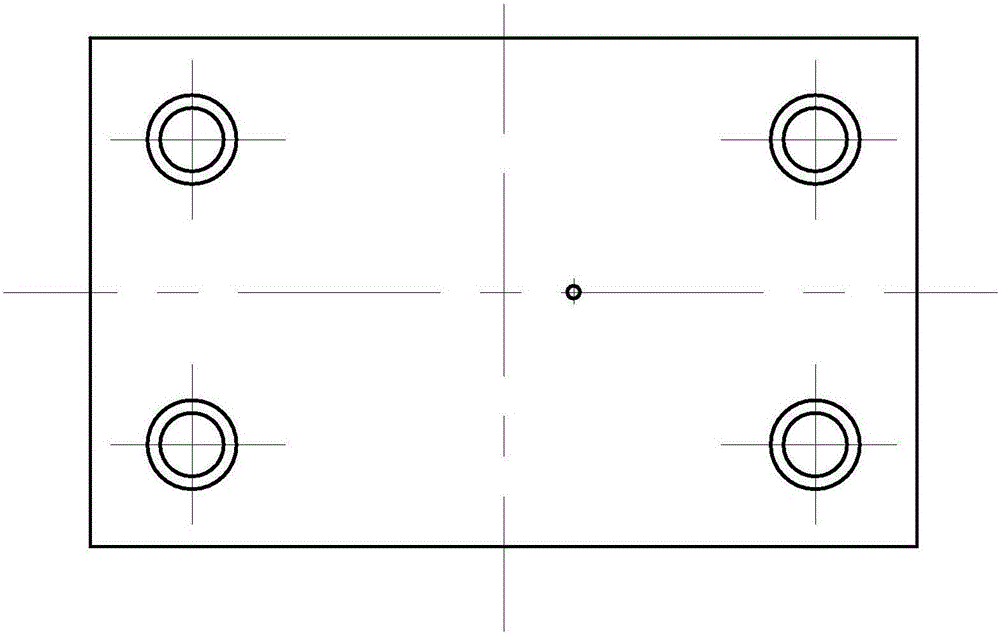

[0049] The upper part of the mold includes the upper mold seat plate 1, the No. 1 hexagon socket head screw 2, the concave mold cavity 3, the upper mold cover plate 4 and the guide sleeve 18,

[0050] The lower part of the mold includes the lower mold seat plate 12, the liquid chamber 8, the second hexagon socket screw 9, two insulating sleeves 10, the guide post 19, the lower mold cover plate 7, the discharge positive electrode 11-1, and the discharge negative electrode 11-2 and wire ...

specific Embodiment approach 2

[0061] Specific embodiment 2: This embodiment is a further description of the thermal electro-hydraulic high-speed impact-quasi-static hydraulic composite forming device described in specific embodiment 1. In this embodiment, it also includes a sealing ring 6, a concave mold cavity A sealing ring 6 is arranged between the cavity 3 and the liquid chamber 8, and the sealing ring 6 is used to provide a sealing effect for the cooperation between the concave mold cavity 3 and the liquid chamber 8.

[0062] In this embodiment, the sealing ring 6 between the concave mold cavity 3 and the liquid chamber 8 provides a sealing effect, and by changing and adjusting the thickness and elasticity of the sealing ring 6, the concave mold cavity 3 can be changed under the condition of providing a certain clamping force. The blank holder force of the plate 5 to be formed is used to achieve the purpose of improving the forming quality.

specific Embodiment approach 3

[0063] Specific embodiment 3: This embodiment is to further explain the thermal electro-hydraulic high-speed impact-quasi-static hydraulic composite forming device described in specific embodiment 1. In this embodiment, the diameter of the metal wire 25 is 0.6 mm to 1.6 mm. mm, the length of the wire 25 is consistent with the groove length of the concave mold cavity 3, and the wire 25 remains parallel to the plate 5 to be processed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com