Waste rubber regenerated rubber compound production system

A production system and technology for waste rubber, applied in the field of recycled rubber production, can solve the problems of difficulty in controlling, destroying sulfur-containing bonds, maintaining the main chain structure of carbon-carbon bonds, etc., achieving small footprint, simple equipment structure, and green environmental performance. The effect of the indicator

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

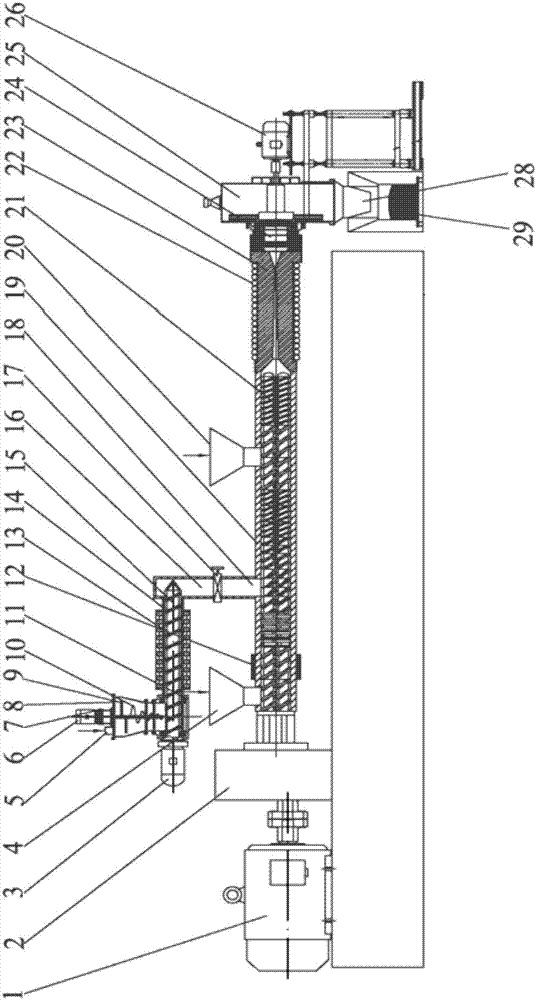

[0023] Such as figure 1 As shown, a production system for waste and old rubber recycled mixed rubber, the production system is composed of three parts: rubber powder single-screw plasticizing device, multi-segment twin-screw extruder with multiple feed ports, and granulation and packaging device. The rubber powder single-screw The plasticizing device is located above the multi-stage twin-screw extruder with multiple feed ports, and the granulation and packaging device is located below the discharge end of the multi-stage twin-screw extruder with multiple feed ports;

[0024] Wherein: the rubber powder single-screw plasticizing device includes a machine barrel 14 with a central axis arranged along the left and right horizontal directions, and a feed inlet is provided on the left side of the top of the machine barrel 14, and a stirring screw feed device is installed on the feed inlet, which includes a hopper 9, The lower end of the hopper 9 is connected to the feed port of the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com