Improved automatic repair machine for PCBA through hole direct insertion device

An improved and automatic technology, applied in electrical components, printed circuit repair/correction, printed circuit secondary treatment, etc., can solve problems such as prolonged tin immersion time, uncontrollable time and precision, heat loss, etc., to avoid high temperature safety Hidden dangers and inconvenience of operation, simplified layout of transmission structure, reduced volume and occupied space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with specific embodiments and accompanying drawings.

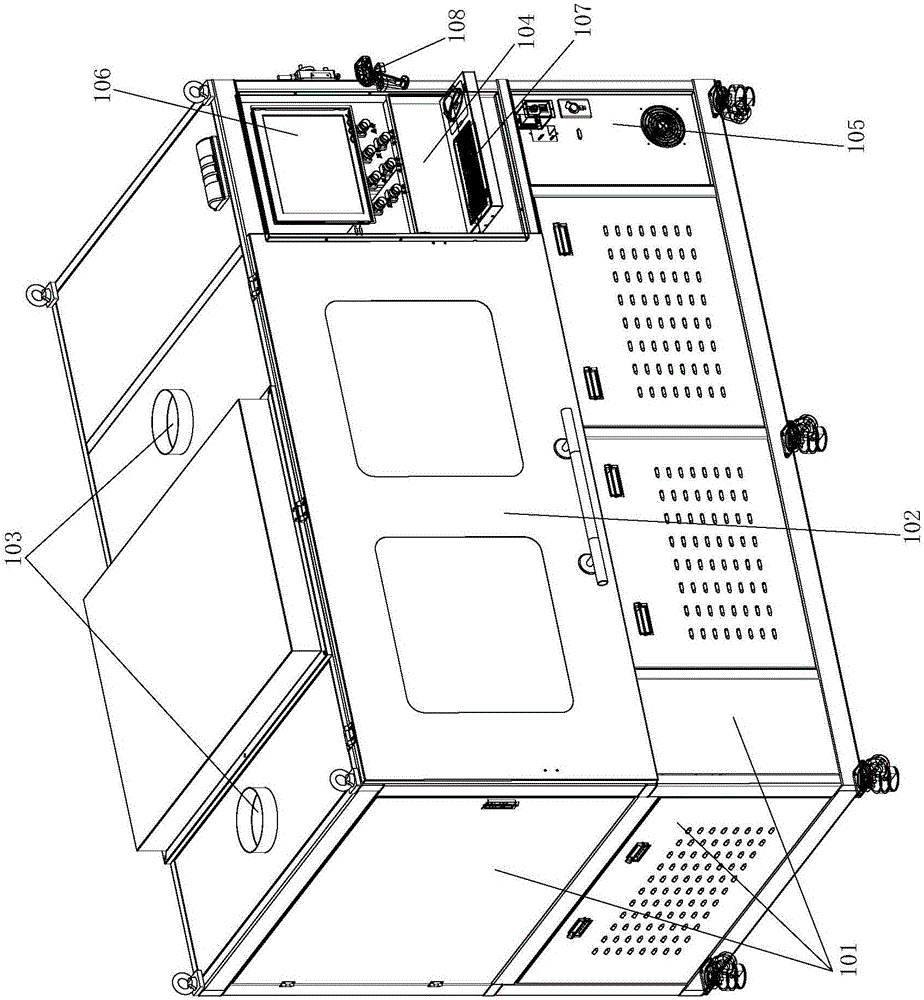

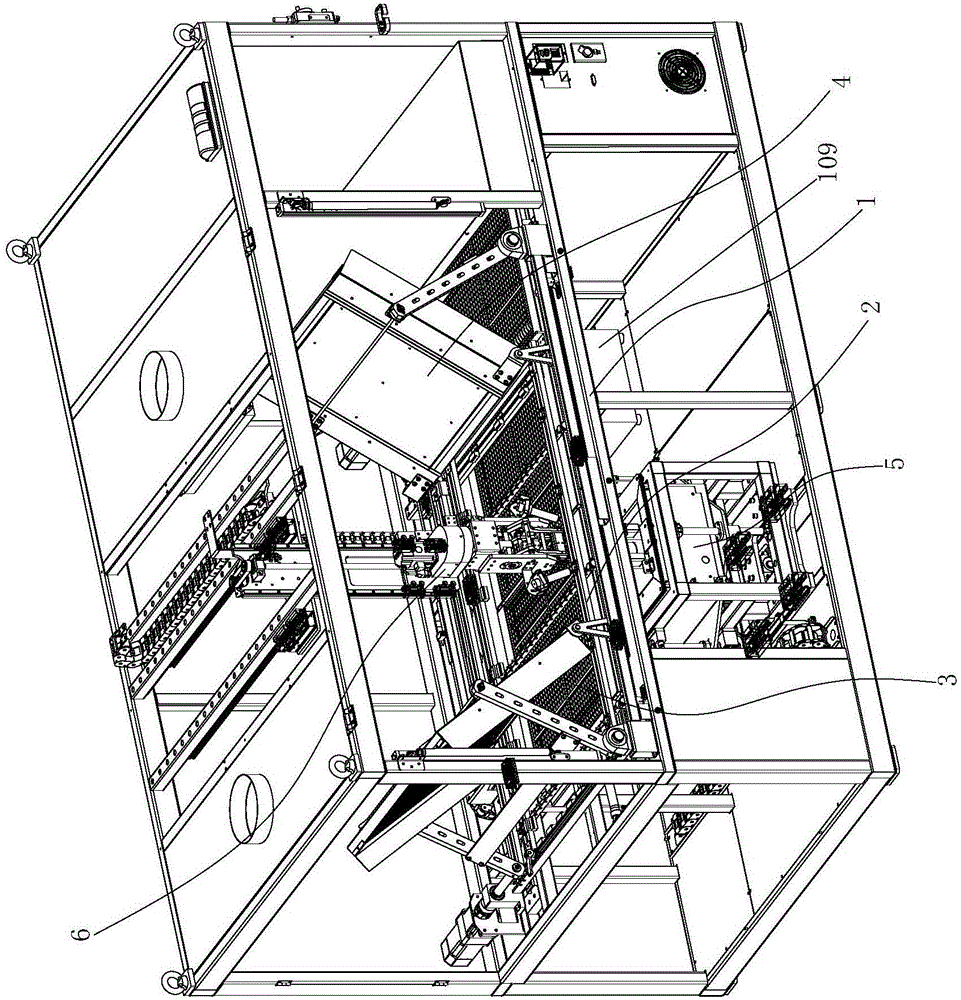

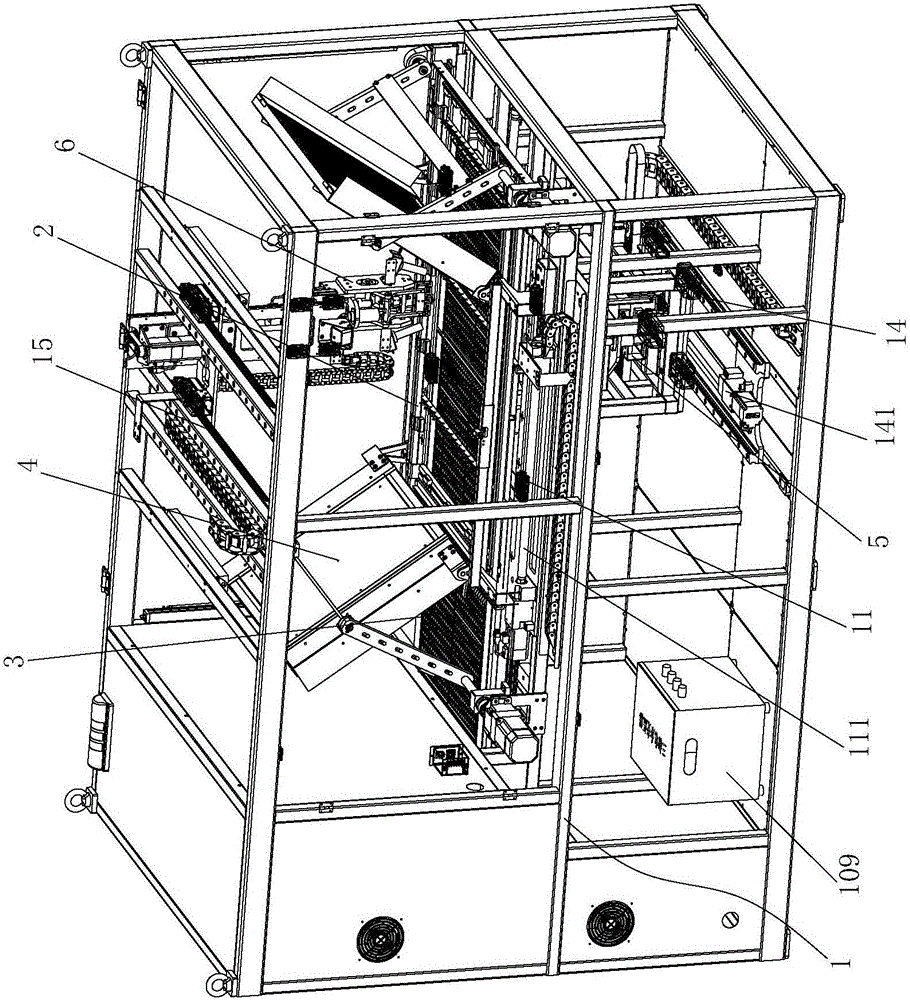

[0036] Such as Figure 1-Figure 3 As shown, what the present invention describes is a kind of automatic rework machine of improved PCBA through-hole in-line device, and this automatic rework machine has a main frame 1, wherein:

[0037] In the middle of the main frame 1, a horizontally arranged first x-direction rail slide assembly 11 and a first x-direction servo drive assembly 111 are installed. The PCBA fixing jig 2 connected to the drive assembly 111;

[0038] combine Figure 6-Figure 7As shown, a second x-guided rail slider assembly 12 is installed in the middle of the main frame 1 and below the PCBA fixing fixture, and the two ends of the second x-guided rail slider assembly 12 are respectively installed with a heating assembly 3, each The lower part of the lower heating assembly 3 is respectively connected with the lower heating assembly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com