Nepheline preheating, pre-decomposing and dry sintering technology and device for producing alumina clinker

A pre-decomposition and alumina technology, which is applied in the preparation of alkali metal aluminate/alumina/hydroxide, chemical industry, sustainable manufacturing/processing, etc., can solve the tension in the supply of high-quality bauxite, bauxite High ore quality requirements, high energy consumption of wet process and other issues, to achieve the effect of expanding production capacity, reducing fuel costs, and convenient pipe layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

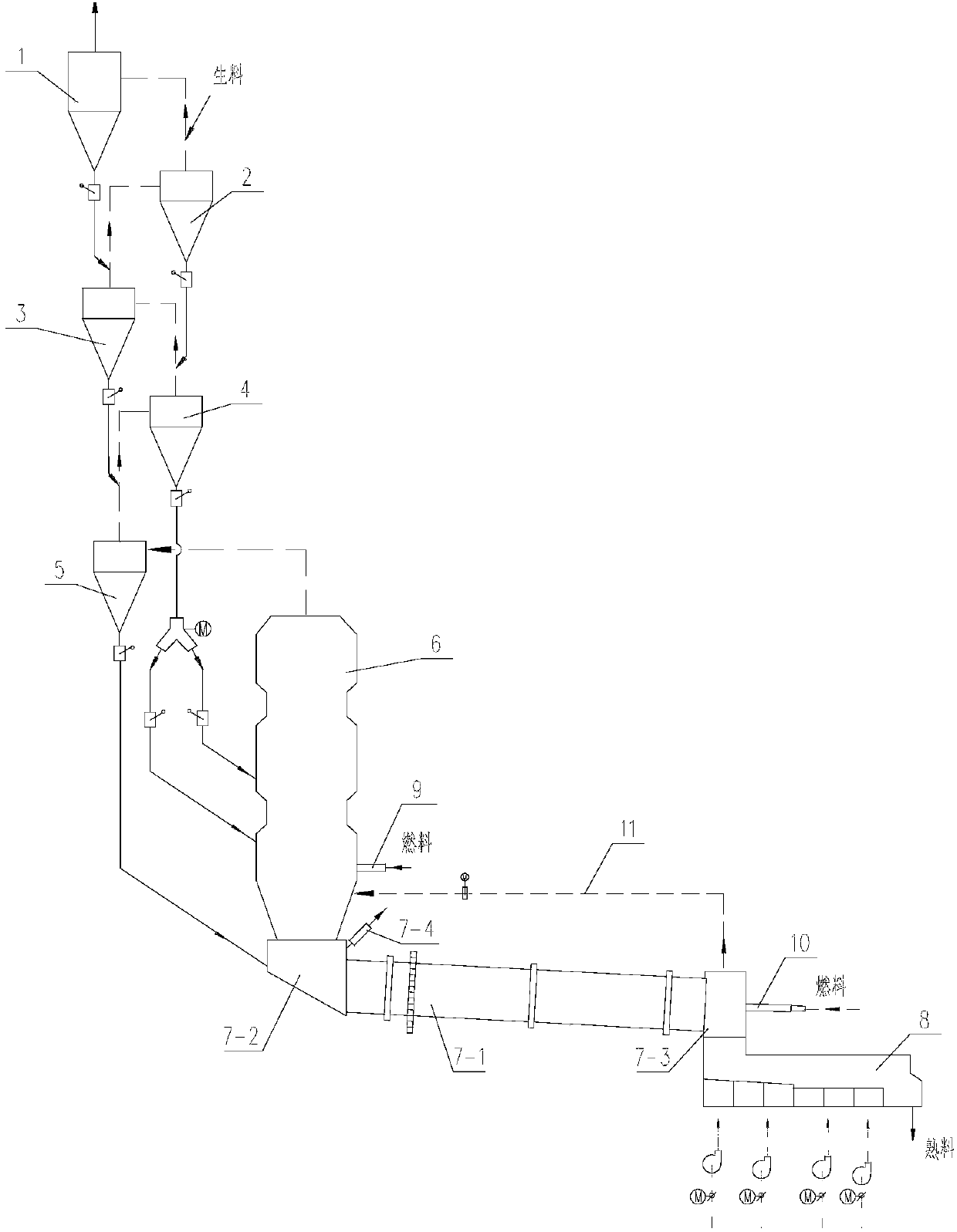

[0032] A process for producing alumina clinker by preheating and pre-decomposing dry sintering of nepheline, comprising the following steps:

[0033] 1) The raw material nepheline, limestone and white slurry are measured in proportions of 30%, 60% and 10% by weight respectively, and the raw meal is obtained by grinding and homogenizing. The rate of the raw meal is the alkali-aluminum ratio Na 2 O / Al 2 o 3 1.8-2.1, calcium silicon ratio CaO / SiO 2 0.9-1.1;

[0034] 2) Send the raw material obtained in step 1) to the preheater; after being preheated by the preheater, it enters the calciner for decomposition, and then enters the rotary kiln for calcination. The calcination temperature of the rotary kiln firing zone is 1200-1400°C The residence time is 20-50 minutes;

[0035] 3) The calcined clinker is cooled by a grate cooler to obtain alumina clinker.

[0036] Among them, the cooling air of the grate cooler exchanges heat with the 1100-1400 ℃ high-temperature clinker exiting...

Embodiment 2

[0038] The difference from Example 1 is that the raw material nepheline, limestone and white slurry are measured in proportions of 45%, 55% and 0% by weight, respectively, and the raw meal is obtained by grinding and homogenizing, and the calcination of the rotary kiln firing zone The temperature is 1250-1350°C, and the residence time in the kiln is 30-40 minutes. The cooling air of the grate cooler exchanges heat with the 1100-1350°C high-temperature clinker exiting the rotary kiln.

Embodiment 3

[0040] The difference from Example 1 is that the raw material nepheline, limestone and white slurry are measured in proportions of 35%, 60% and 5% by weight, respectively, and the raw meal is obtained by grinding and homogenizing, and the calcination of the rotary kiln firing zone The temperature is 1300-1400°C, and the residence time in the kiln is 20-35 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com