Integrated production system for integrated wall panel

A production system and integrated wall technology, applied in building components, applications, home appliances, etc., can solve problems such as inability to guarantee continuous production, and achieve the effects of reducing temperature difference, improving film quality, and bonding firmly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

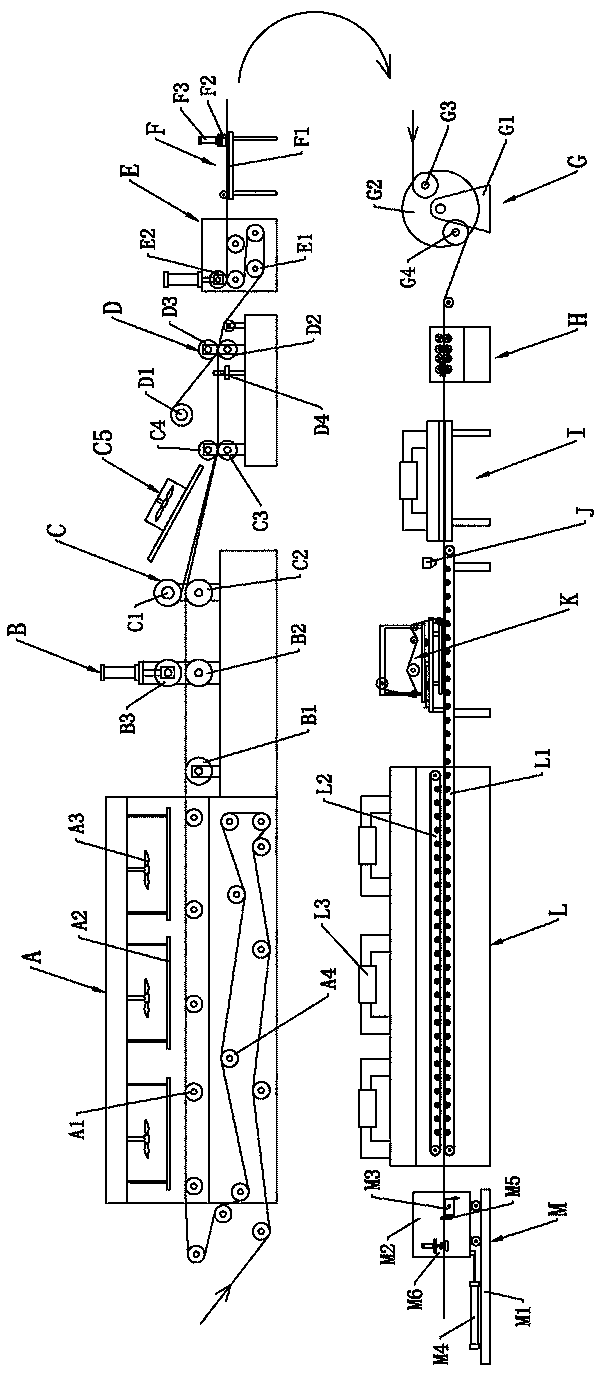

[0045] Example: such as Figure 1 to Figure 6 As shown, the integrated production system of integrated wall panels includes:

[0046] Oven A is used to heat the base tape;

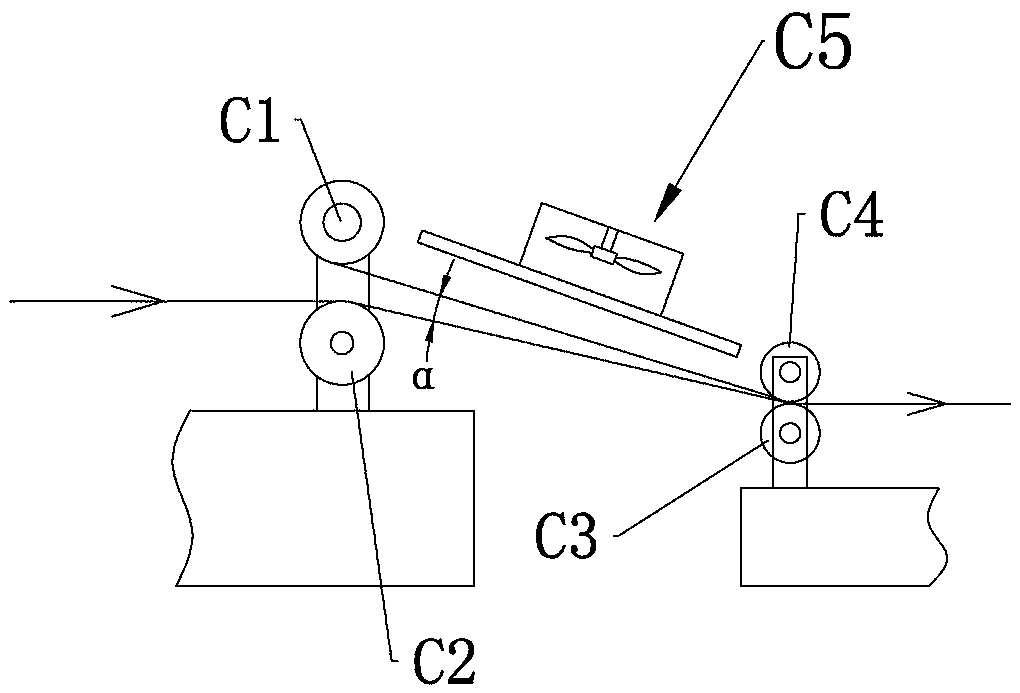

[0047] A PVC coating mechanism C is arranged at the outlet of the oven A, and is used to cover the surface of the base belt with a PVC film;

[0048] The protective film coating mechanism D is arranged behind the PVC film coating mechanism C, and is used to cover the surface of the PVC film with a protective film to form a composite base belt;

[0049] The composite pressing mechanism E is arranged behind the protective film laminating mechanism D;

[0050] The clamping mechanism F is arranged behind the composite pressing mechanism E;

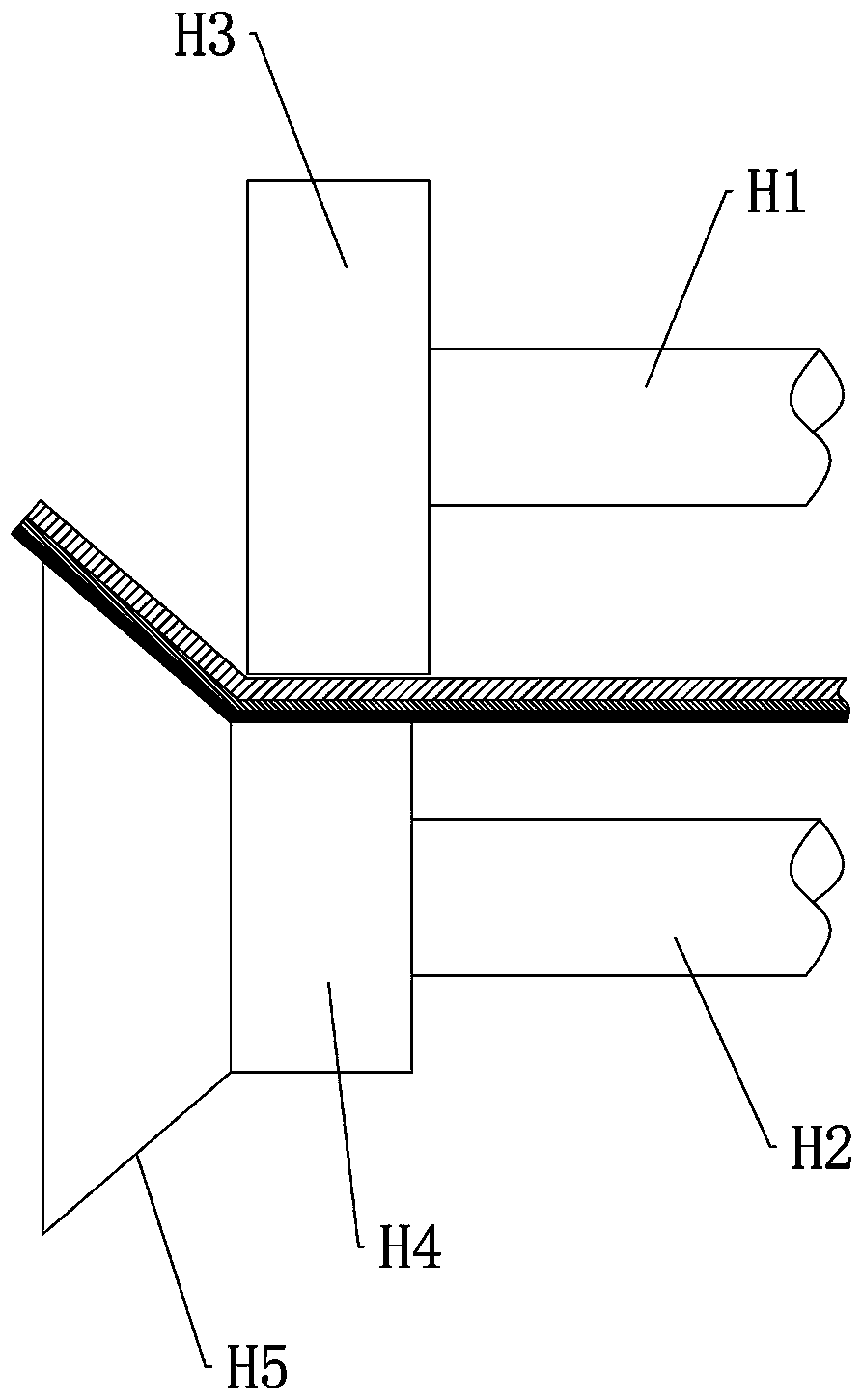

[0051] The tongue and groove forming mechanism H is arranged behind the clamping mechanism F;

[0052] The temporary storage mechanism G is used for winding and unwinding the composite base tape, and is arranged between the clamping mechanism F and the tenon-groove for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com