Eccentric air heating furnace

A hot blast stove, eccentric technology, applied in the field of hot blast generation equipment, can solve the problems of insufficient heating, waste of energy, high wind pressure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

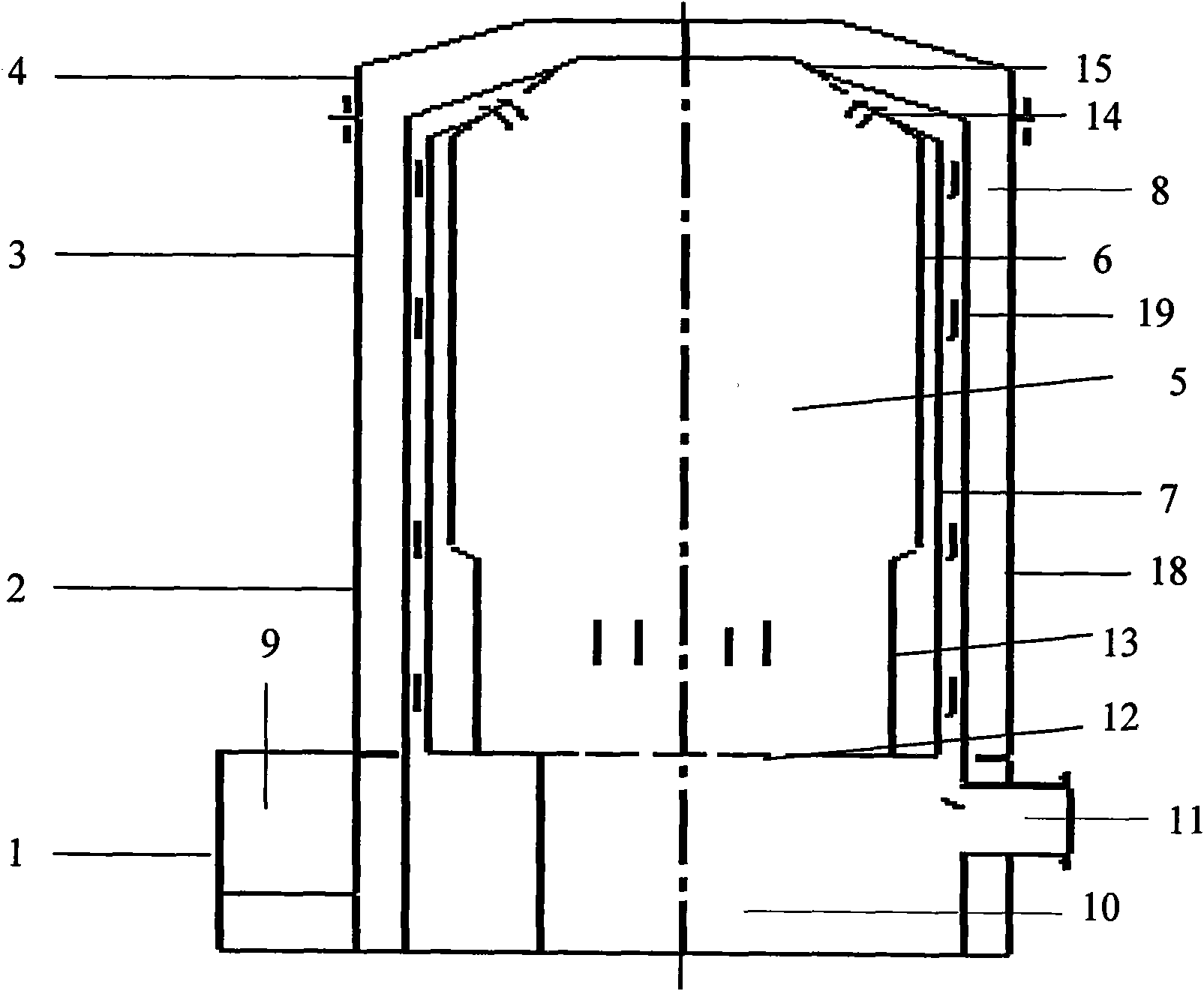

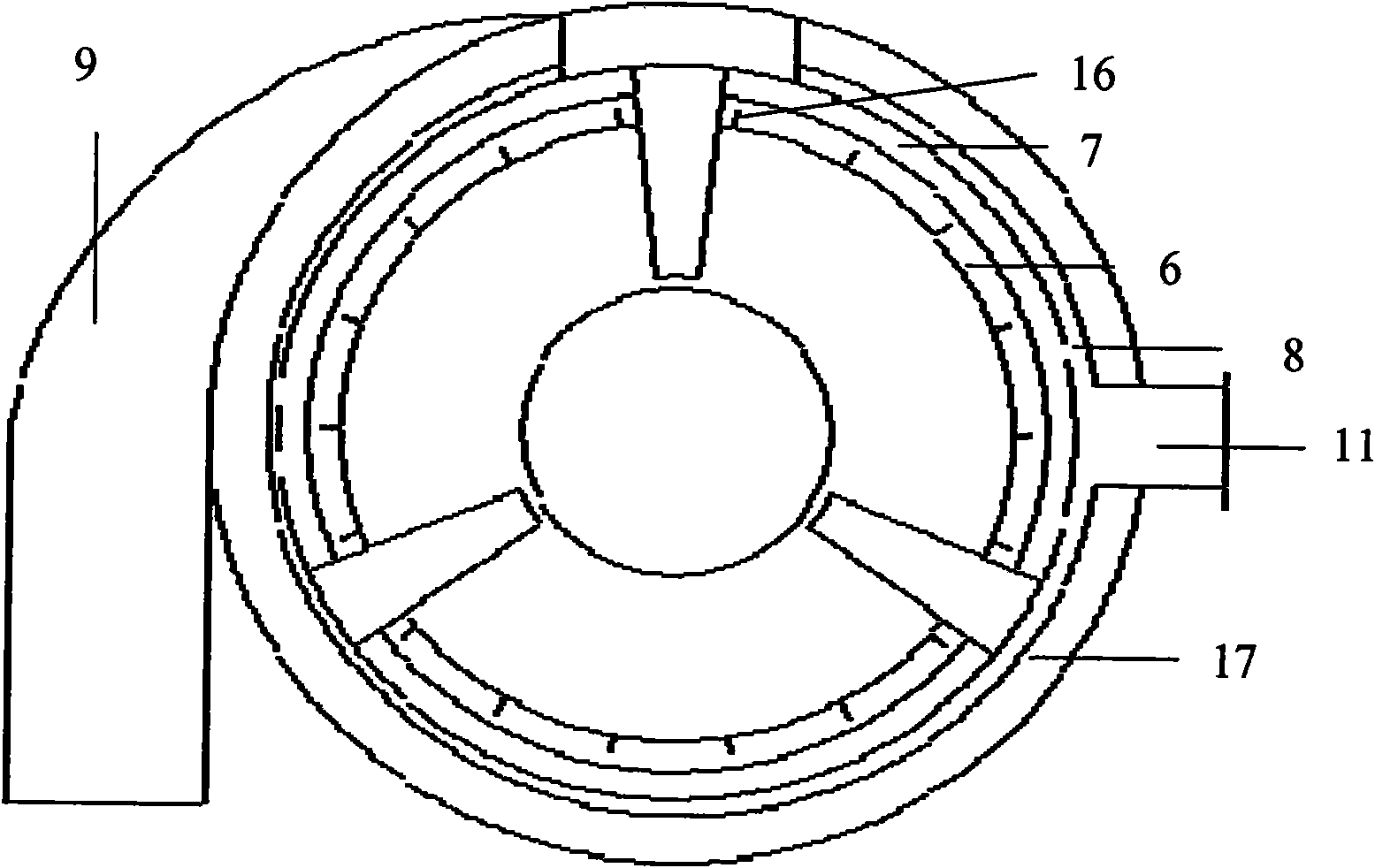

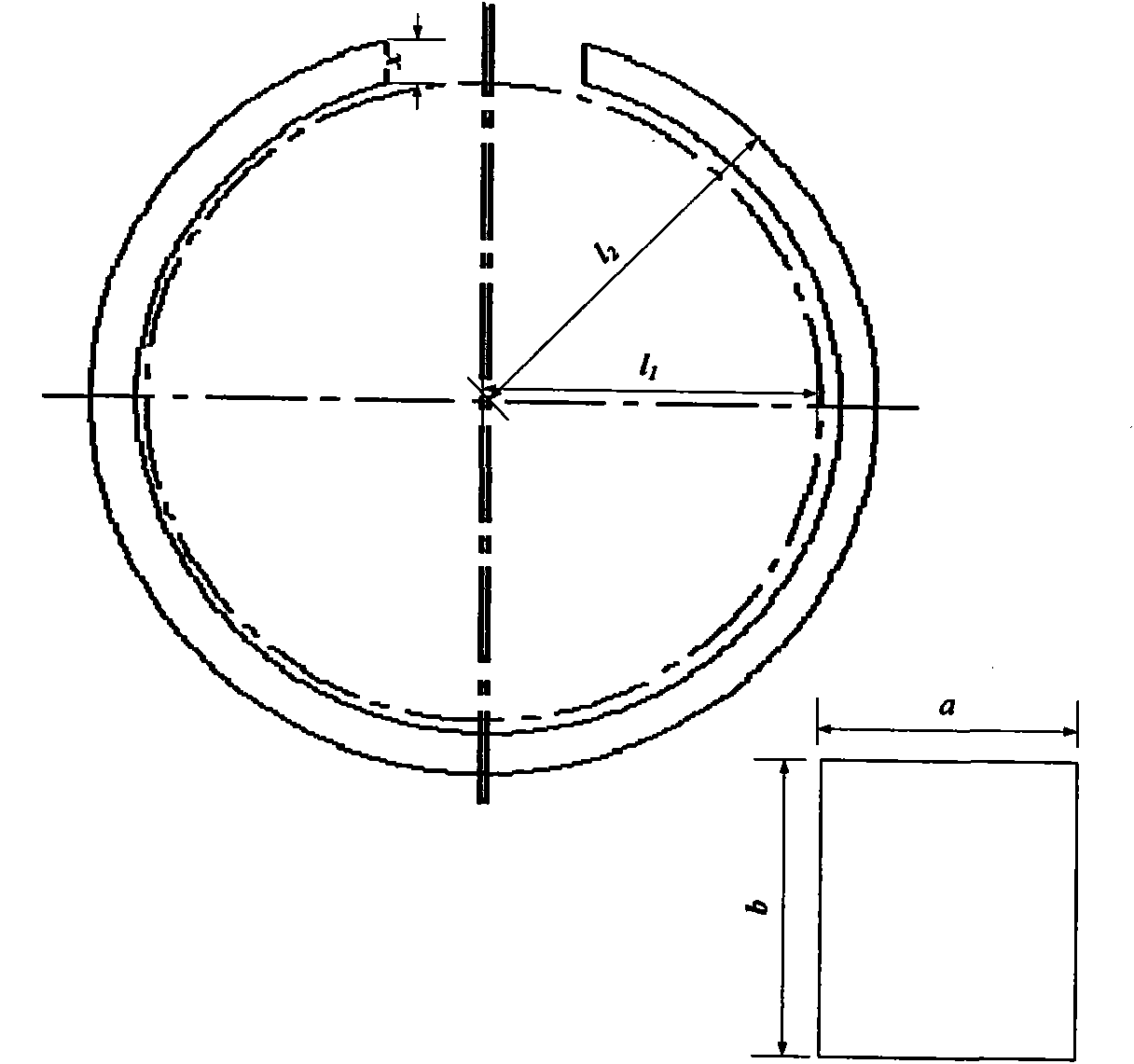

[0015] In the eccentric hot blast stove of the present invention, the furnace body of the energy-saving hot blast stove is divided into three parts from bottom to top: the lower part of the furnace body (1), the middle part of the furnace body (2), the upper part of the furnace body (3) and the top of the furnace body (4) , the hot blast stove is divided into four layers from the inside to the outside: the combustion chamber (5), the warm air space layer (6), the flue gas space layer (7) and the cold air space layer (8), and the lower part of the furnace body (1) includes the air inlet (9), cinder chamber (10) and smoke outlet (11), fire grate (12) is between body of heater middle part (2) and body of heater bottom (1), and body of heater middle part (2) is because fuel burns The part has the highest temperature, so there are refractory bricks (13) in the innermost layer of the middle part of the furnace body (2), and the middle part of the furnace body and the upper part of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com