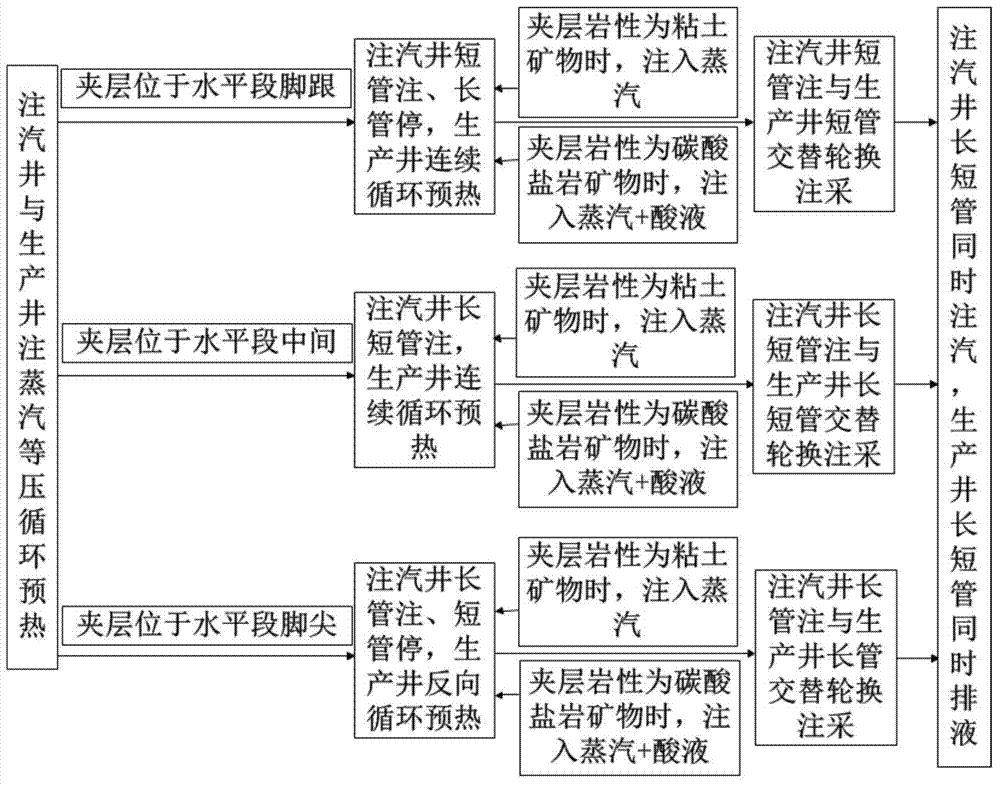

SAGD starting method for interlayer heterogeneous thickened oil pool

A heavy oil reservoir, heterogeneous technology, applied in the direction of earthwork drilling, production fluid, wellbore/well components, etc., can solve the problem that it is difficult to develop steam chambers, it is difficult to establish oil drainage channels, and the development of steam chambers in the horizontal section is affected. SAGD well production and recovery factors, to achieve the effect of simple operation and uniform heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

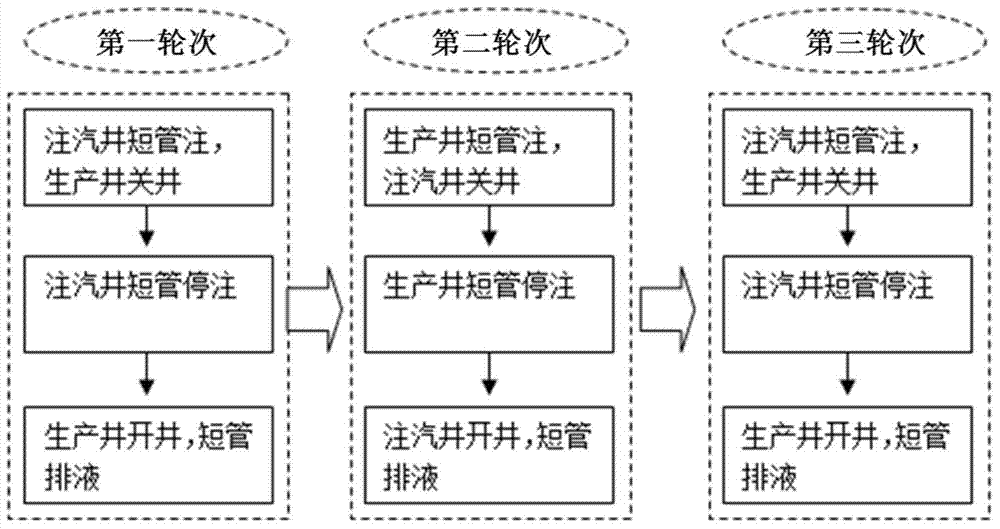

[0058] Present embodiment provides a kind of interlayer heterogeneous heavy oil reservoir SAGD start-up method, there is interlayer 5 (such as Figure 5 shown), and the distribution of interlayer 5 along the horizontal section is 1 / 2 the length of the horizontal section (the horizontal section is 300 meters long), the thickness of interlayer 5 is 0.3 meters, and the lithology of interlayer 5 is mudstone. The distance between the horizontal sections of the injection-production wells is 5 meters. Parallel double oil pipes are run in the wellbore of the injection-production wells. The long (oil) pipes are run into the toe of the horizontal section, and the short (oil) pipes are run into the heel of the horizontal section. Include the following steps:

[0059] Step 1: Steam injection well 3 and production well 6 are preheated for 60 days in equal pressure circulation;

[0060] Among them, the preheating method is steam injection in the long pipe 4 and liquid drainage in the short...

Embodiment 2

[0070] This embodiment provides a kind of interlayer heterogeneous heavy oil reservoir SAGD starting method, there is interlayer (such as Figure 6 shown), and the interlayer spread along the horizontal section is 1 / 3 of the length of the horizontal section (the horizontal section is 300 meters long), the thickness of the interlayer is 1 meter, and the lithology of the interlayer is tight sandstone. The distance between the horizontal sections of the injection-production wells is 5 meters. Parallel double oil pipes are run in the wellbore of the injection-production wells. The long (oil) pipes are run into the toe of the horizontal section, and the short (oil) pipes are run into the heel of the horizontal section. Include the following steps:

[0071] Step 1: Steam injection wells and production wells are preheated for 75 days in isobaric steam injection cycles;

[0072] Among them, the preheating method is long-tube steam injection and short-tube liquid drainage; the bottomh...

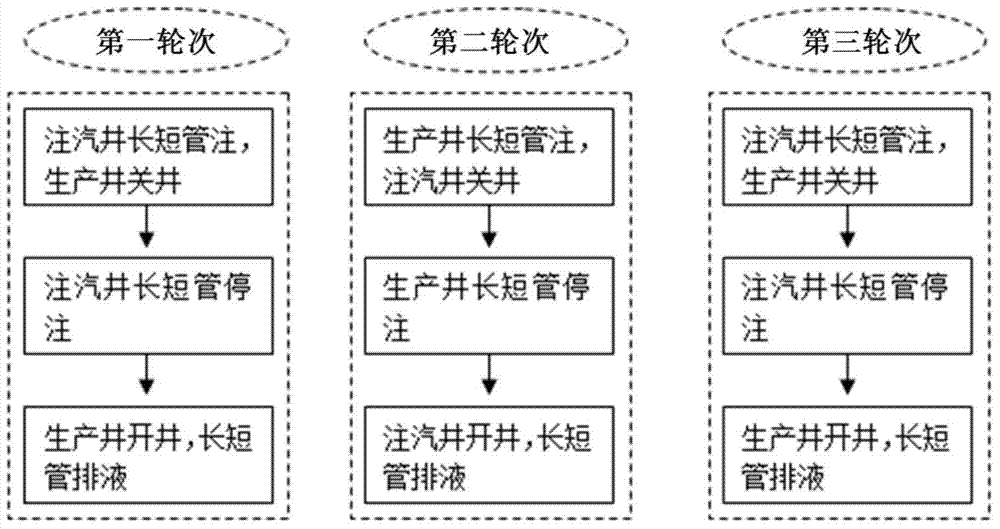

Embodiment 3

[0082] This embodiment provides a method for starting SAGD in an interlayer heterogeneous heavy oil reservoir. There is an interlayer (such as Figure 7 shown), and the interlayer spread along the horizontal section is 1 / 2 the length of the horizontal section (the horizontal section is 500 meters long), the thickness of the interlayer is 3 meters, and the lithology of the interlayer is carbonate rock. The distance between the horizontal sections of the injection-production wells is 5 meters. Parallel double oil pipes are run in the wellbore of the injection-production wells. The long (oil) pipes are run into the toe of the horizontal section, and the short (oil) pipes are run into the heel of the horizontal section. Include the following steps:

[0083] Step 1: Steam injection wells and production wells are preheated for 90 days in isobaric steam injection cycles;

[0084] Among them, the preheating method is long-pipe steam injection and short-pipe liquid drainage; the botto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com