Concentric sleeve type five-layer coextrusion film blower handpiece

A co-extrusion blown film, sleeve-type technology, which is applied in the field of concentric sleeve-type five-layer co-extrusion blown film head, can solve problems such as loading and unloading, transportation troubles, processing machine tools that are incapable of processing tasks, and large pressure loss of molten materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

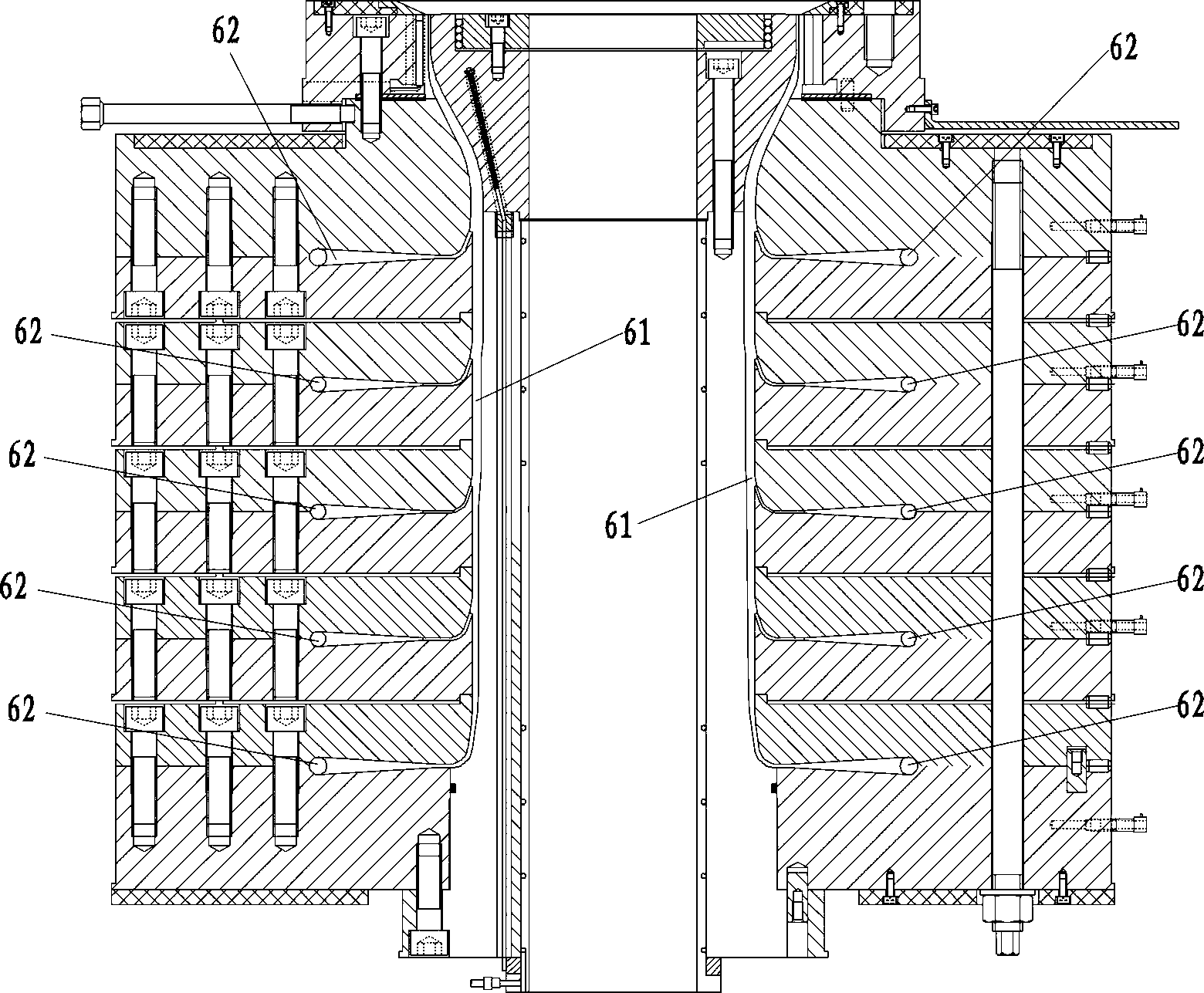

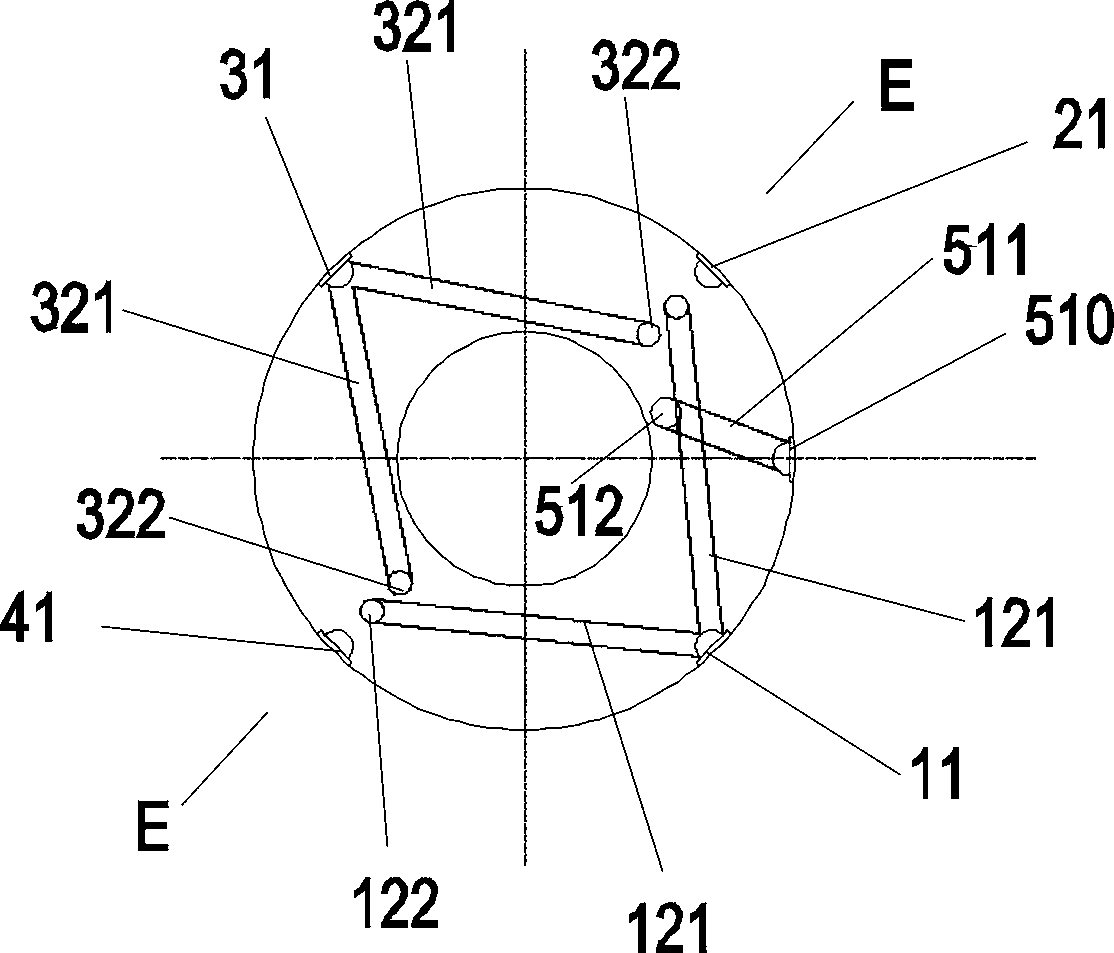

[0097] The concentric sleeve type five-layer co-extrusion film blowing head of this embodiment includes five sets of flow channel systems, each set of flow channel systems corresponds to guiding the flow of one layer of molten material before the film bubble is extruded; each set of flow channel systems It includes a layer of spiral flow channel on the upper part of the machine head and a general feeding port on the lower part of the machine head.

[0098] Image 6 , Figure 35 , Figure 36 As shown, the upper part of the machine head is provided with six concentric sleeves, each of which is nested inside and outside. The central axis of the machine head becomes the central axis m of the machine head; a layer of spiral flow channels is formed between the interface of two adjacent concentric sleeves, and the five layers of spiral flow channels are arranged in order from outside to inside according to the diameter, respectively. The spiral flow channel 57 , the second outer s...

Embodiment 2

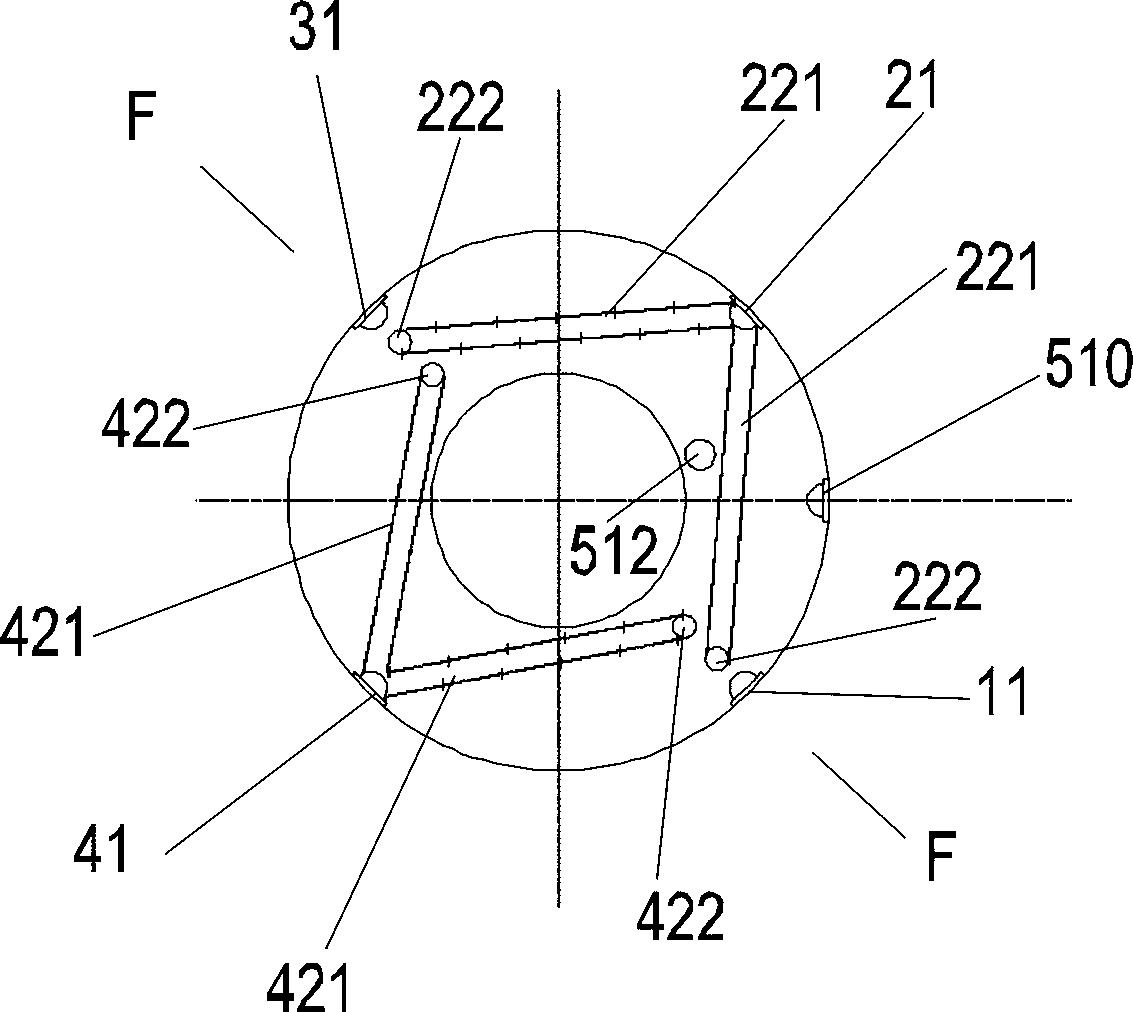

[0130] In the second embodiment, the vertical main flow channel 512 of the fifth set of flow channel system is staggered by an azimuth angle of 153° relative to the main feed inlet 11 of the first set of flow channel system, and the staggered direction is counterclockwise.

[0131] In this way, compared with Embodiment 1, the structures of the first runner system, the second runner system, and the fourth runner system of Embodiment 2 are exactly the same as those of Embodiment 1, while the fifth runner system of Embodiment 2 The runner system is staggered counterclockwise by 90° relative to the fifth runner system in the first embodiment.

[0132] In fact, the fifth set of flow channel system in Embodiment 2 starts from the horizontal sorting branch channel 543, and its downstream flow channels (including the horizontal sorting branch channel 543) are symmetrically the same with respect to the 90° rotation of the center of the machine head. Therefore, the second embodiment The...

Embodiment 3

[0136] In the third embodiment, the vertical main flow channel 512 of the fifth set of flow channel system is staggered by an azimuth angle of 18° relative to the main feed port 11 of the first set of flow channel system, and the staggered direction is counterclockwise;

[0137] In this way, compared with Embodiment 1, the structures of the first runner system, the second runner system, and the fourth runner system of Embodiment 3 are exactly the same as those of Embodiment 1, while the fifth embodiment of Embodiment 3 The set of runner systems is staggered clockwise by 45° relative to the fifth set of runner systems in Embodiment 1, and the distribution of runners on the third interface is as follows: Figure 37 shown.

[0138] In fact, the fifth set of flow channel system in the third embodiment starts from the radial branch channel 544, and its downstream flow channels (including the radial branch channel 544) are symmetrical and the same with respect to the 45° rotation of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com