Manufacturing method of commercial high-magnesium aluminum alloy wheel hubs

A technology of high-magnesium aluminum alloy and aluminum alloy wheels, which is applied in the directions of wheels, vehicle parts, transportation and packaging, etc., can solve the problems of low production efficiency, high energy consumption, complex process, etc., and achieve improved production efficiency, high performance, and simplified The effect of craft

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0075] Take a 22.5-inch automotive aluminum alloy wheel as an example:

[0076] The 5083 aluminum alloy hot-rolled plate is punched into a ring-shaped blank with an outer diameter of Φ800mm and an inner diameter of Φ260mm;

[0077] Preheat the ring-shaped blank to 380°C, spin and draw it into a disc shape;

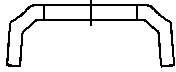

[0078] Put the cooled disc-shaped blank into the forging die, and use the forging press to cold forge the spoke part;

[0079] Heat the forged aluminum alloy wheel blank to 150°C, and spin the forged aluminum alloy wheel blank on the spinning machine to form a hollow rotating body hub blank;

[0080] Then the hollow rotating body hub blank is kept in a continuous annealing furnace at 200°C for 1 hour; finally, the hub is machined and followed by surface treatment to obtain an automotive aluminum alloy hub product.

[0081] The aluminum alloy wheels obtained in the above examples were selected for corresponding mechanical performance tests, and samples were taken at diffe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com