A kind of electrospinning rotary spinneret and using method thereof

An electrospinning and spinning device technology, applied in the field of electrospinning rotary spinning device, can solve the problems of high brittleness of nanofibers, limited application performance and scope, etc., achieve uniform force on inner wall, improve material utilization, increase The effect of high pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

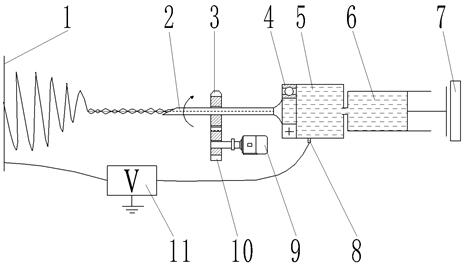

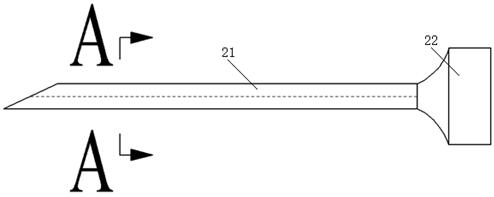

[0033] In this embodiment, the electrospinning rotary spinning device, such as figure 1 As shown, it includes a micro injection pump 7 , a syringe 6 , a bearing sleeve 5 , a bearing 4 , a needle 2 , a receiving plate 1 and a high voltage power supply 11 .

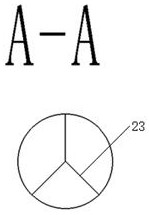

[0034] Injection tube 6 is arranged on microinjection pump 7 by clamp, as Figure 4 As shown, the bearing sleeve 5 has a stepped inner cavity, which includes a bearing connection cavity 51, a transition cavity 52 and an injection tube connection cavity 53 arranged in sequence. The inner diameter of the bearing connection cavity 51 is larger than the injection tube connection cavity. The inner diameter of the cavity 53, the transition cavity 52 is an inner cavity formed by the smooth transition from the bearing connection cavity 51 to the injection tube connection cavity 53, and the smooth transition protrudes outward, and the bearing sleeve 5 is used to connect the bearing 4 and the injection tube 6 , the inside of which i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com