Rubber continuous vulcanization unit extruder screw

A technology of connecting sulfur and generating units

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and embodiments. It should be noted that the following descriptions are for explaining the present invention and not limiting its content.

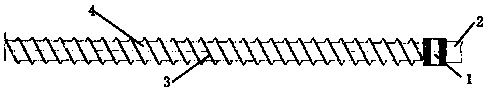

[0021] Such as figure 1 As shown, the present invention discloses an extruder screw of a rubber continuous vulcanization unit, comprising a screw head 1 and a stud 2 with an integrated structure of the screw head, the stud is provided with an uninterrupted screw edge 3, and the long diameter of the screw The ratio is 16:1; the entire section of the stud is a double-start thread 4 with equal distances and different depths. The volume ratio of a screw groove is 1.56.

[0022] The screw head is in the shape of a torpedo head.

[0023] The thread pitch is equal to the diameter of the screw.

[0024] The pitch of the screw is 160 mm, and the flight width is 9 mm.

[0025] The groove depth of the screw gradually changes from 24.57mm to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pitch | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com