Method for Producing a Road Surface, Preferably a concrete road surface, and road paver

a road surface and concrete technology, applied in the direction of roads, roads, roads, etc., can solve problems such as particularly complicated

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

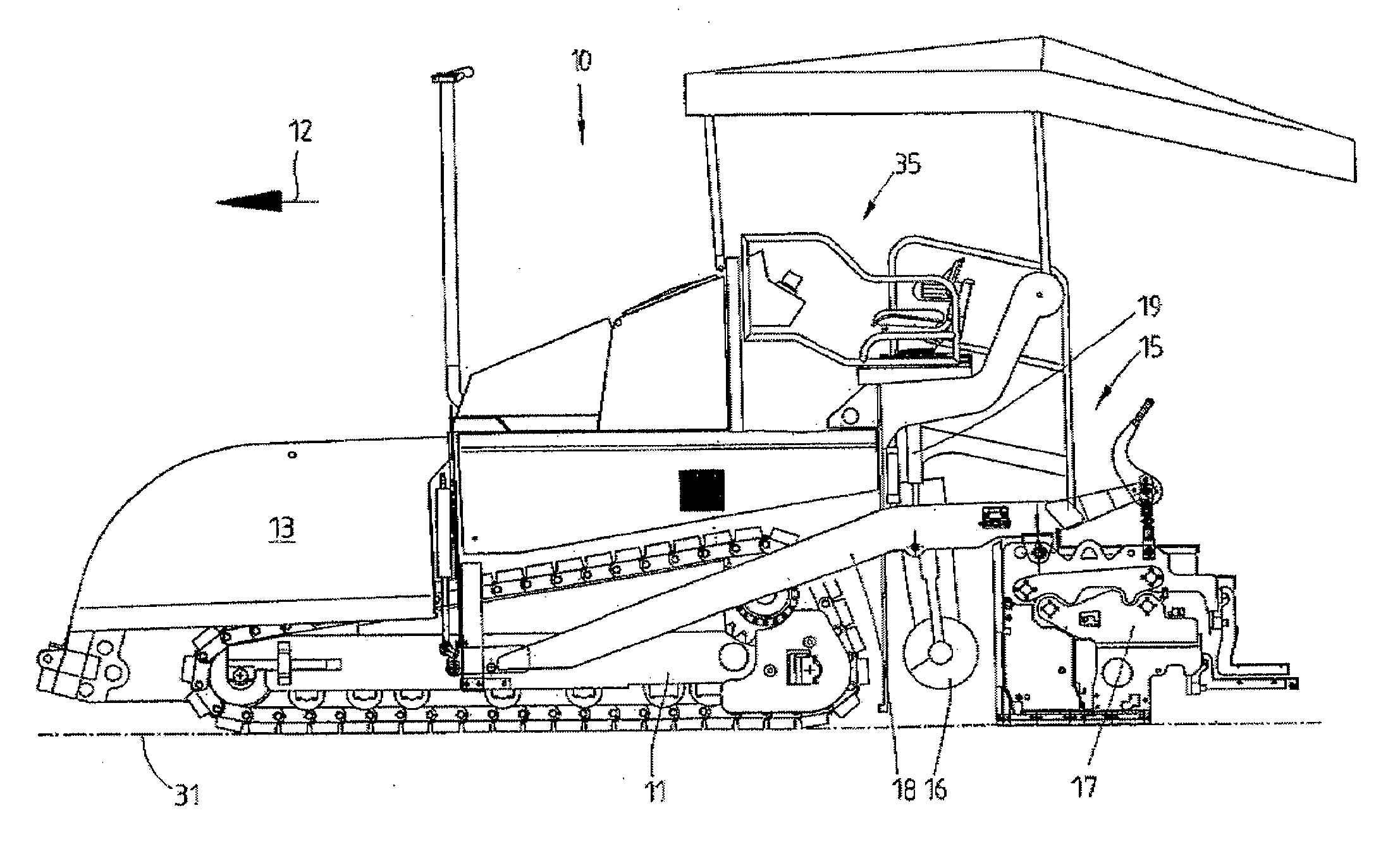

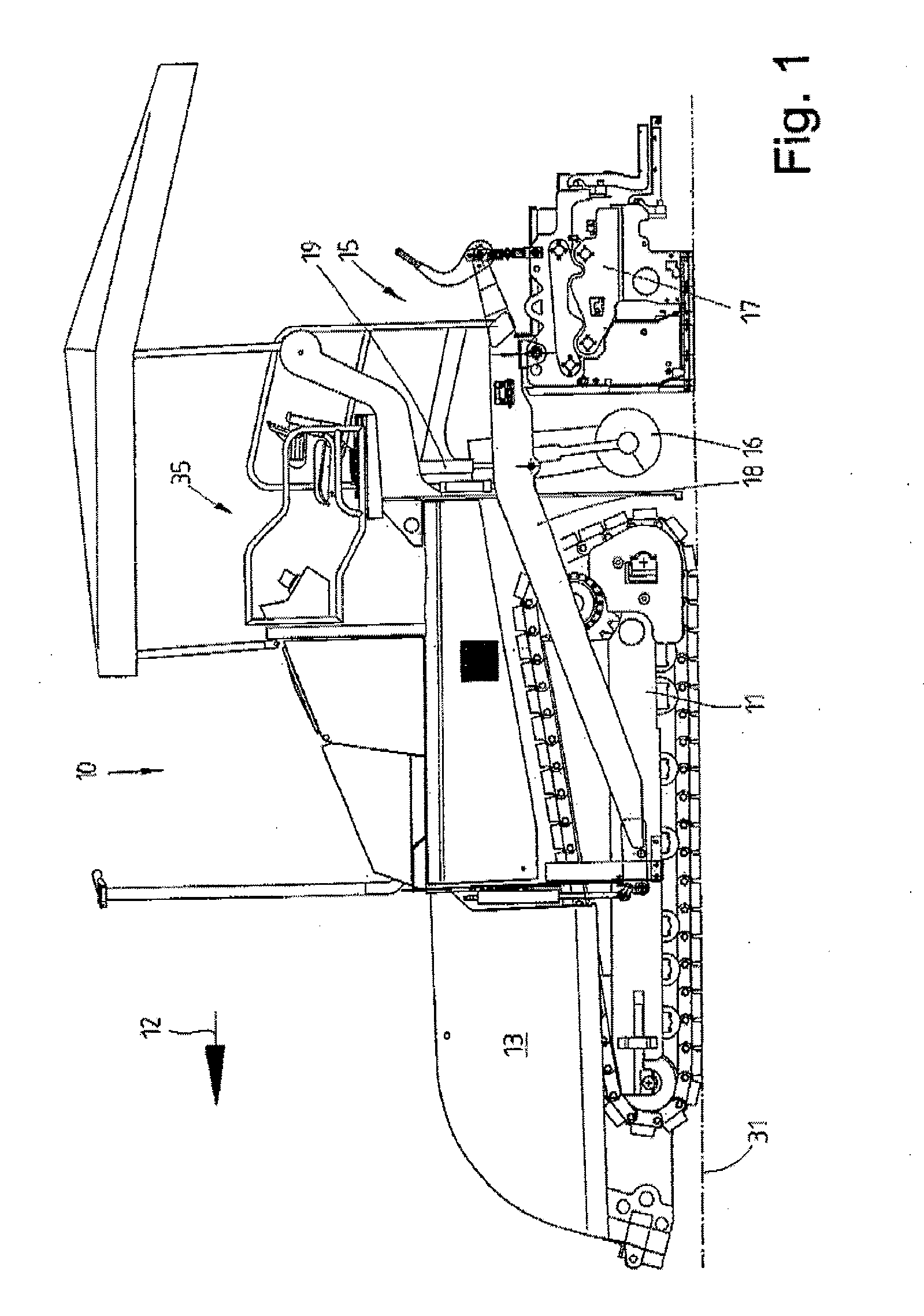

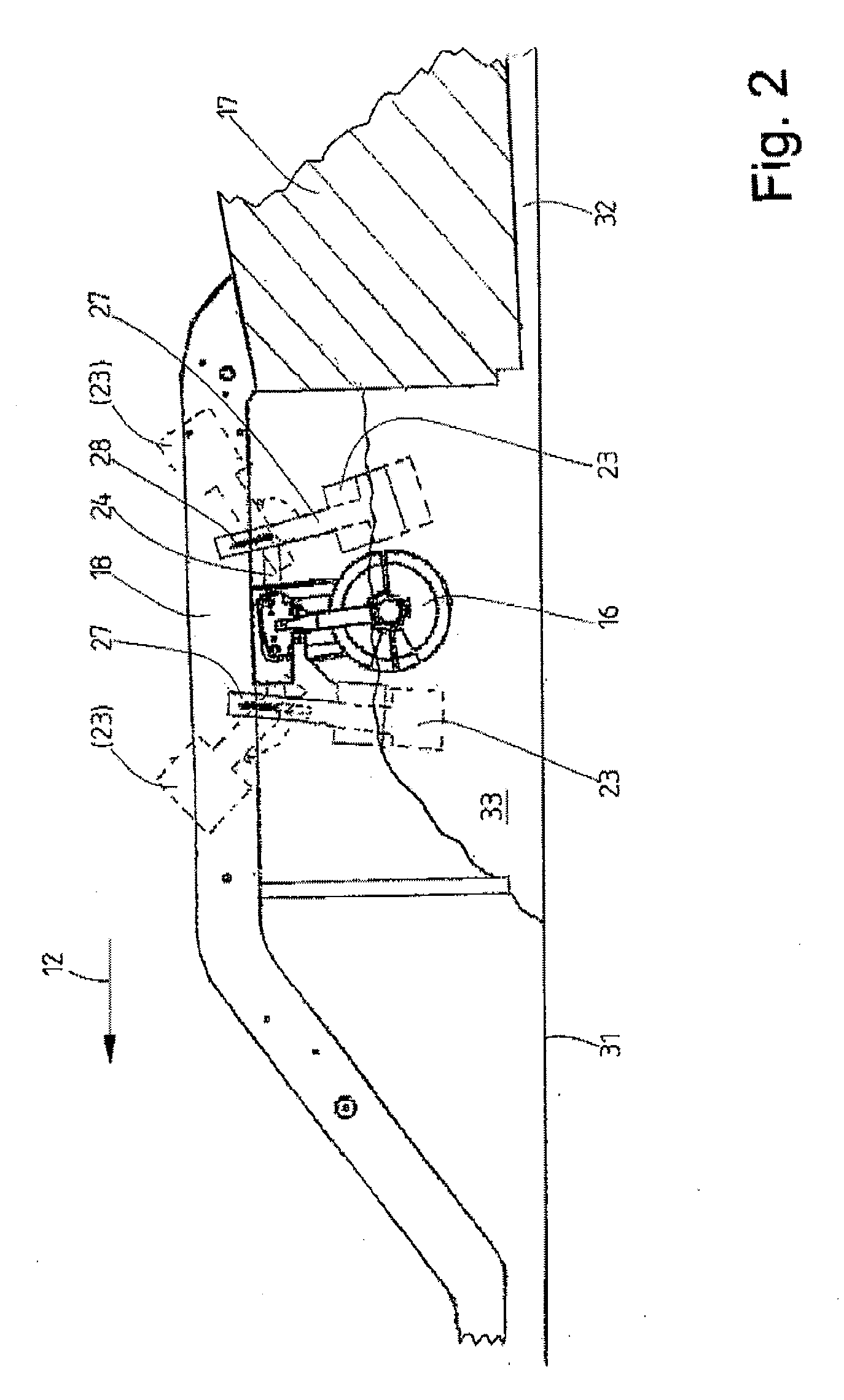

[0024]FIG. 1 schematically shows a road paver 10 which is designed according to the invention in such a way that it serves not only for producing an asphalt road surface but is also suitable for producing a concrete road surface. The road paver 10 is also especially suitable for applying a concrete wearing course to an existing asphalt road surface whose worn wearing course has been removed, for example, by milling.

[0025]The road paver 10 has a set of running gear 11 which in the exemplary embodiment shown is designed as a tracked running gear. The running gear of the road paver 10 can, however, also be a wheeled running gear.

[0026]As seen in the paving direction 12, a well-like or trough-like reservoir 13 is arranged on the front of the road paver 10. The reservoir 13 serves to accommodate a supply of the material serving for the production of the road surface, namely an asphalt mixture if the road paver 10 is used to produce an asphalt road surface. By means of a conveying member,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com