High-temperature liquid furnace slag conveying method using valve conveying device

A valve device and high-temperature technology, which is applied in the field of rotary sealing valves and rotary sealing valve devices, can solve the problems of small number of valve blades, poor sealing effect, and inability to meet the pressure and sealing output requirements of high-temperature slag, so as to reduce rotational frictional resistance and ensure Effect of sealing pressure and oil supply pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

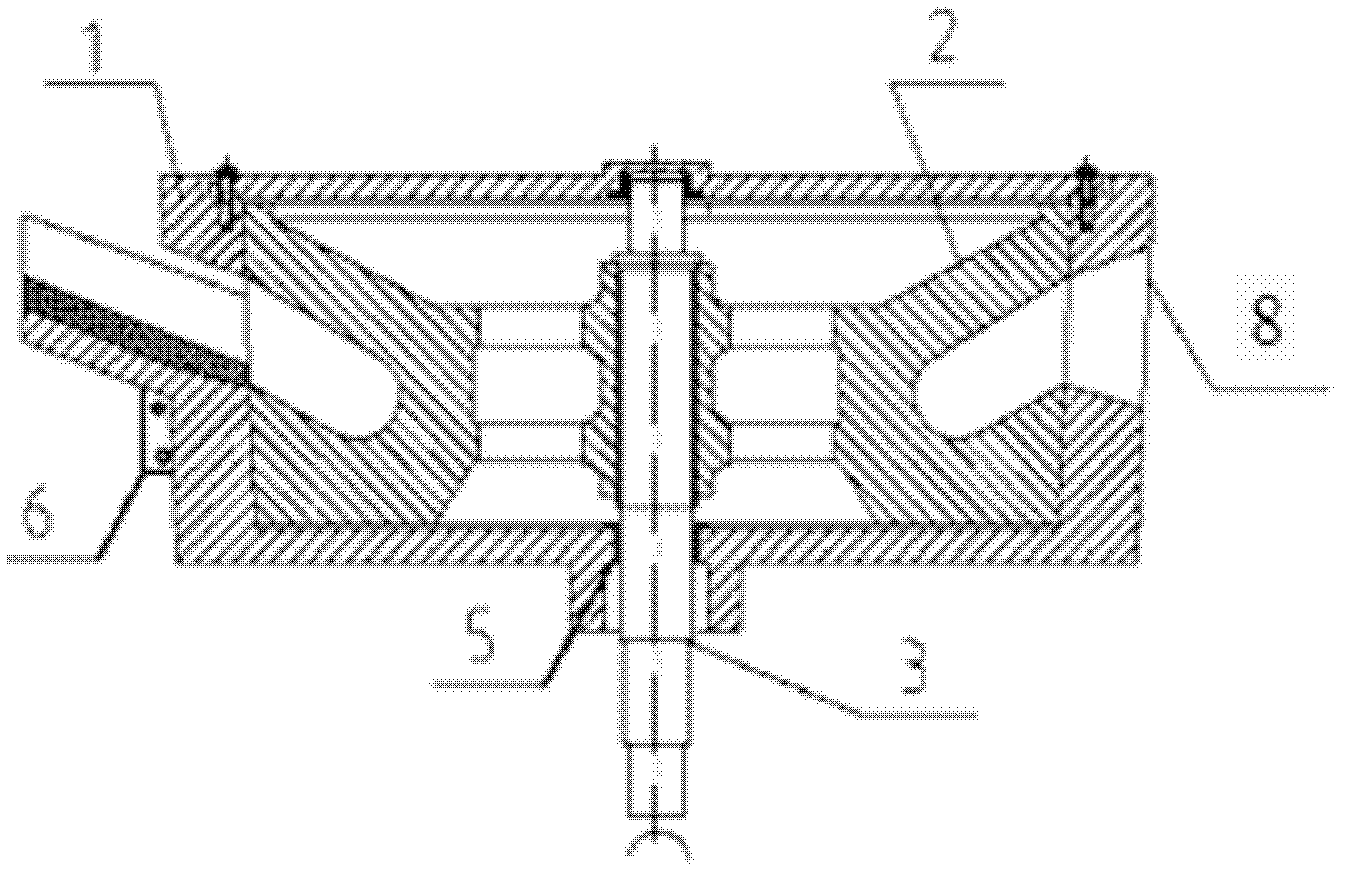

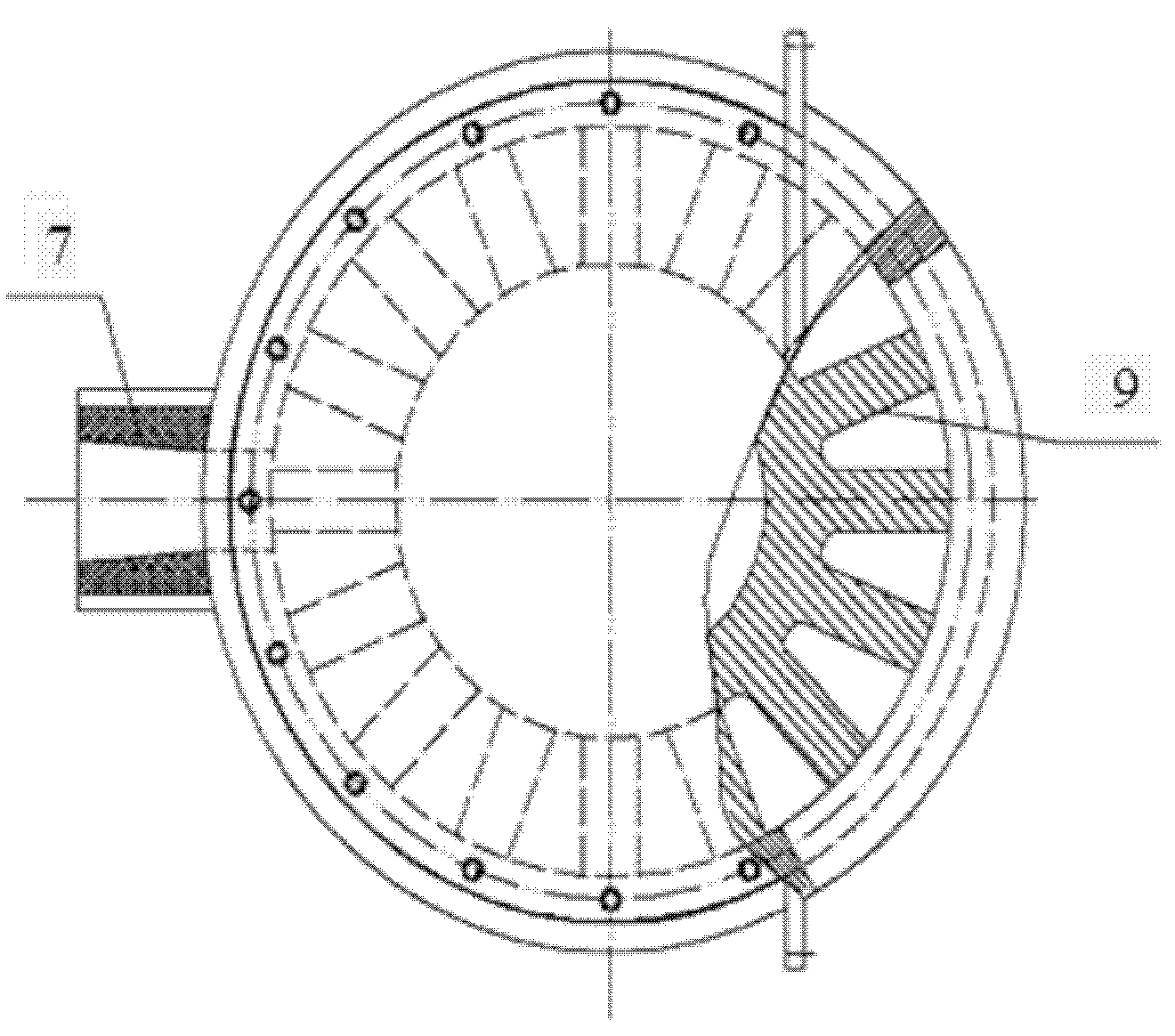

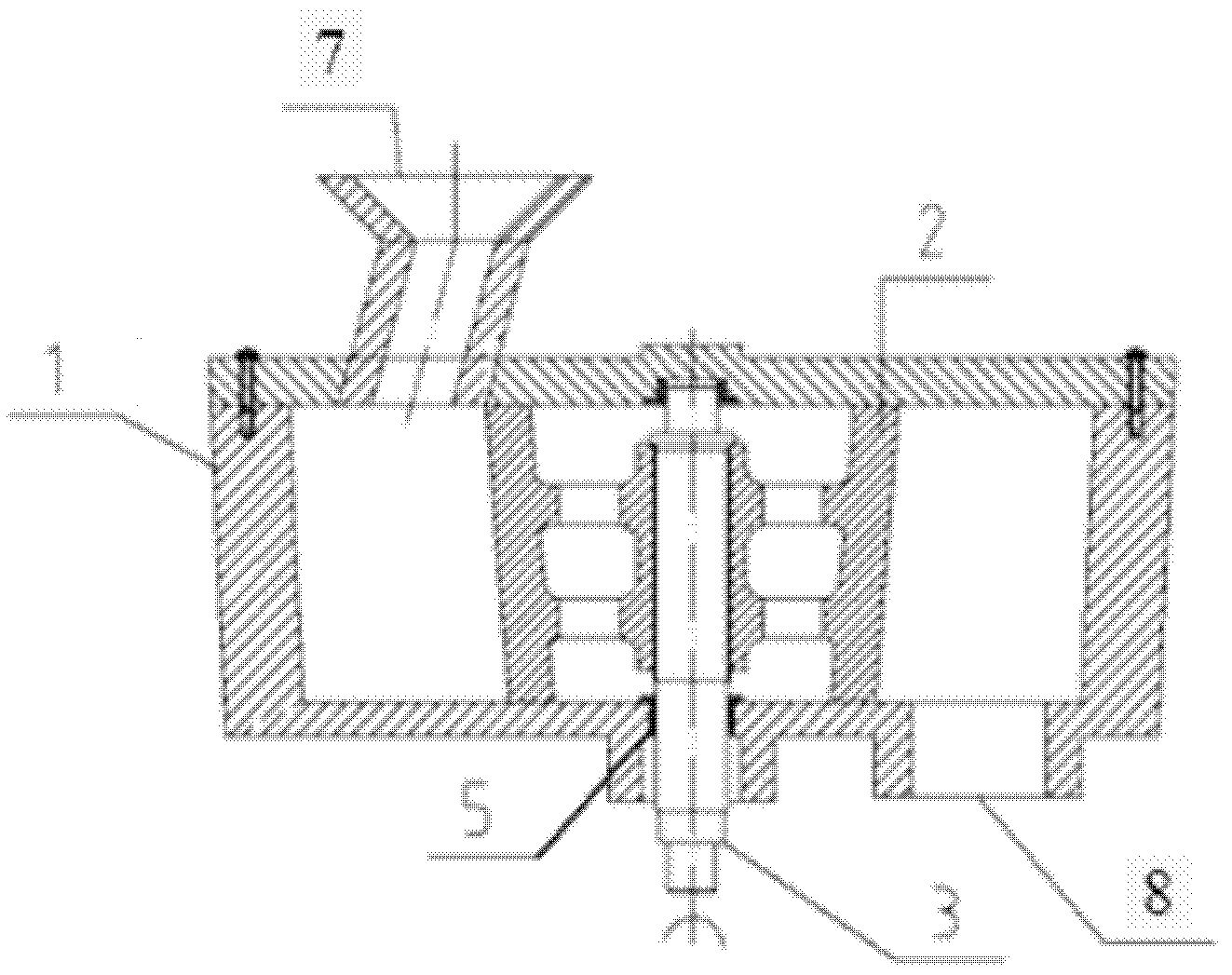

[0019] Embodiment 1~5 of the present invention will be described in further detail below in conjunction with accompanying drawing: Embodiment 1 is as follows: figure 1 , figure 2 The conveying valve device used in the method of conveying high-temperature liquid slag using the conveying valve device shown is mainly composed of a shell 1, an impeller 2, a shaft 3, a bearing 5, a water wall 6, a slag inlet 7, a slag outlet 8, Composed of blades 9, the shell 1 is subdivided into a slag inlet 7 and a slag outlet 8, the impeller is subdivided into a hub and 16 blades 9, the impeller is divided into 16 cavities by 16 blades 9, and the impeller 2 rotates It is installed in the shell 1 in a matching manner, the blade 9 forms a rotary seal with the shell 1, the upper part of the shell 1 is provided with an end cover, and the shell 1 is provided with a slag inlet 7 and a slag outlet 8 with a cooling wall 6, The stave 6 is installed on the outside of the slag inlet 7; the bearing 5 is i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com