Guide vane exit circulation homogenizer for axial-flow pump and guide vane type mixed-flow pump model

A technology of a homogenizer and a mixed-flow pump, which is applied to the components, pumps, and pump elements of a pumping device for elastic fluids, can solve the problems such as the inability to study the hydraulic performance and unevenness of the water outlet, and achieve a simple and reasonable structure. , easy to implement, innovative and ingenious effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

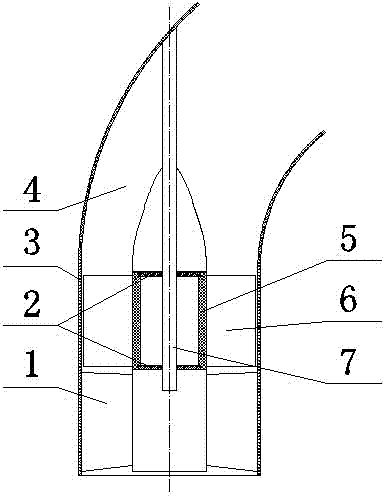

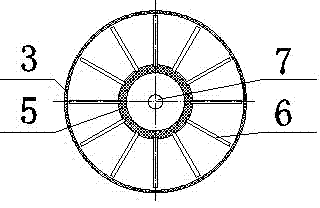

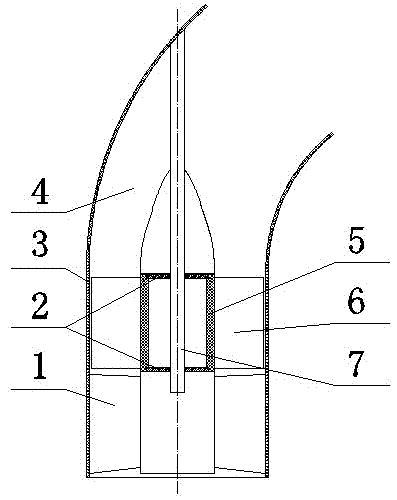

[0013] Such as figure 1 , figure 2 As shown, the axial flow pump and guide vane mixed flow pump model guide vane outlet circulation homogenizer, one end of the circulation homogenizer is connected to the outlet of guide vane body 1 of the model pump, and the other end is connected to the outlet of the model pump The inlet of the water outlet flow channel 4 is connected, and the circulation homogenizer is composed of a hollow hub 5, a straight blade 6, a fixed shaft 7 and a support hole 2, and the fixed shaft 7 is connected with the model pump shaft, the guide The central axis of the blade body hub is a concentric shaft, and the diameter of the hub 5 is the same as that of the guide vane hub of the pump. The end is provided with a support hole 2, and the hub is freely threaded on the fixed shaft through the holes on the support holes at both ends of the hub. The diameter of the straight blade 6 is 1-2 mm smaller than the diameter of the outlet pipeline of the guide vane body...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com