Swing gates for emergency barriers

A barrier and cylinder technology, applied in the field of swing gates for emergency barriers, can solve problems such as unsuitable for moving applications and large overall structure, and achieve the effects of easy handling, increased contact area, and easy disassembly and assembly operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

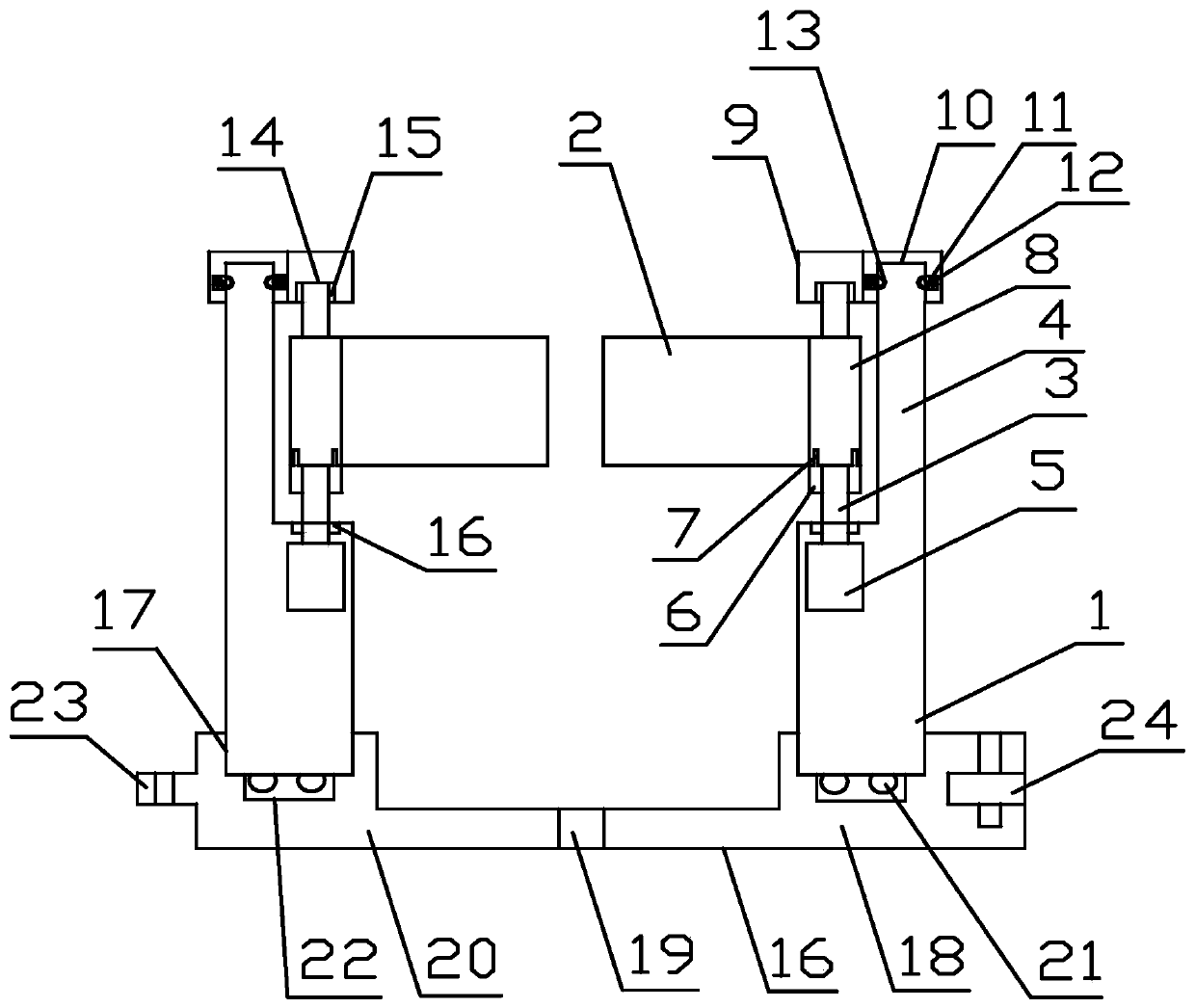

[0032] Such as figure 1 As shown, the present invention provides a swing gate suitable for emergency obstacles, including two cylinders 1 with the same structure and two baffles 2 with the same structure, the axial end of the cylinder 1 is provided with a rotating shaft 3 and a fixed Rod 4, the axial direction of the rotating shaft 3, the axial direction of the fixed rod 4 and the axial direction of the cylinder 1 are parallel; the rotating shaft 3 is driven and rotated by the motor 5 arranged in the cylinder 1, and the rotating shaft 3 is axially at the bottom end side A limit plate 6 is arranged on the wall along the circumferential ring, and a limit bar 7 protrudes upward on the limit plate 6; a connecting sleeve 8 is provided on one side of the baffle plate 2, and the axial bottom of the connecting sleeve 8 The end surface is concavely provided with a limit groove adapted to the limit bar 7, the connecting sleeve 8 is sleeved on the rotating shaft 3, and the limit bar 7 is...

Embodiment 2

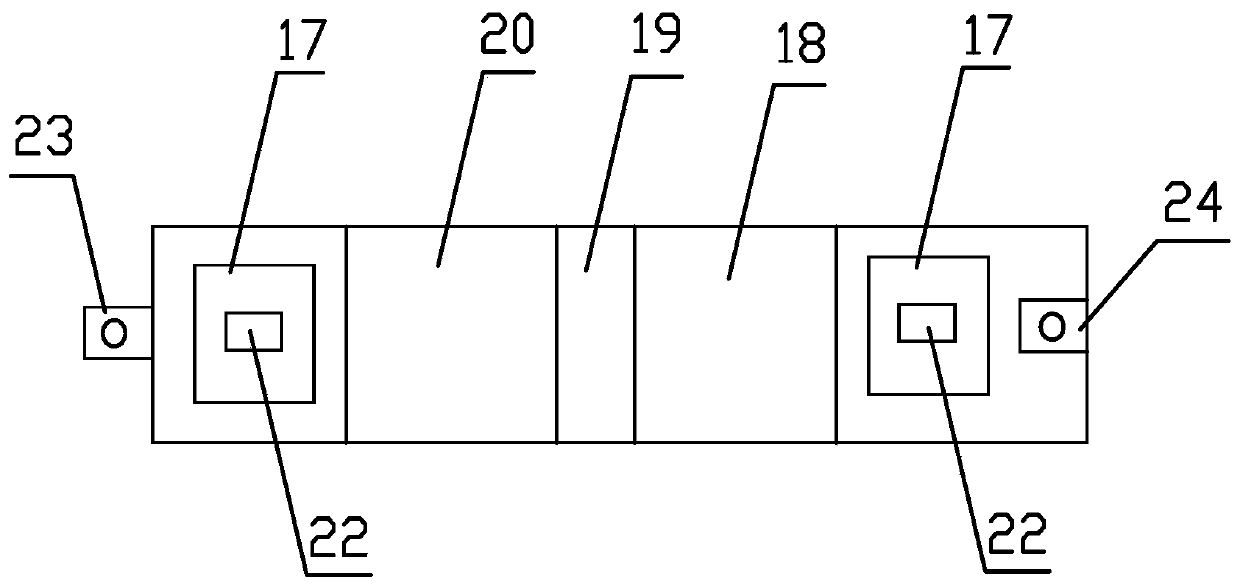

[0034] Further improvement on the basis of Embodiment 1, the base 16 includes a first support plate 18, a transition plate 19 and a second support plate 20 connected end to end in sequence, and the installation groove 17 is provided on the first support plate 18 and the second support plate. The end of the support plate 20 away from the transition plate 19; the first support plate 18 and the transition plate 19 are connected by a hinge, and the transition plate 19 and the second support plate 20 are connected by a hinge.

Embodiment 3

[0036]Further improvement on the basis of Embodiment 2, the axial bottom end surface of the cylinder 1 is provided with a traveling wheel 21 , and the inner bottom of the installation groove 17 is also provided with a traveling wheel groove 22 for accommodating the traveling wheel 21 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com