A steel ingot turning machine

A steel ingot and spherical roller bearing technology, applied in the direction of workpiece manipulation, etc., can solve the problems of small wheels (rollers are easy to deviate or get stuck, poor stability and startability, affecting the normal operation of the turntable, etc.) The effect of balanced force and improved service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

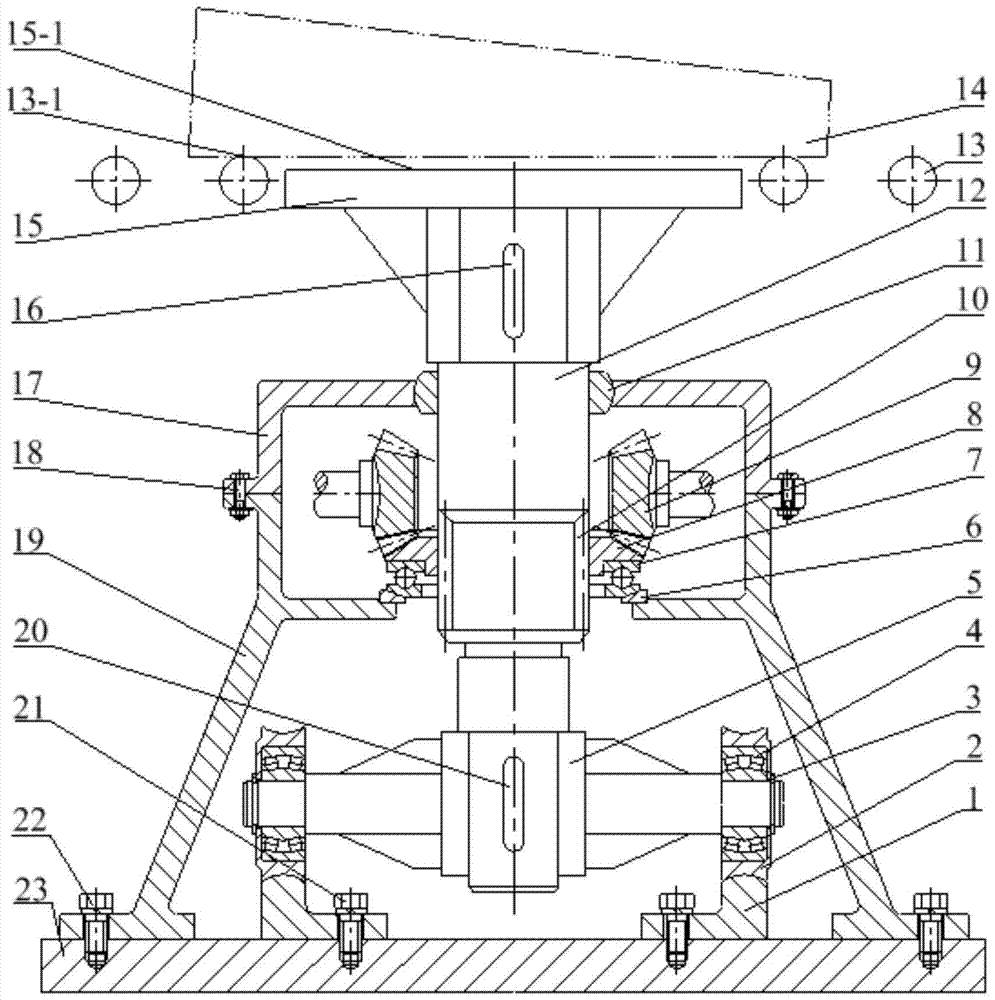

[0028] The structure and usage of the steel ingot turning machine according to the present invention will be further described below through examples and in conjunction with the accompanying drawings.

[0029] In this embodiment, the structure of the steel ingot turning machine is as follows: figure 1 As shown, it includes base 23, track body 1, sheave 2, locking ring 3, spherical roller bearing 4, connecting frame 5, main shaft 12, driving bevel gear 9, driven bevel gear 8, transmission shaft 25, spherical Seat 6, thrust ball bearing 7, motor 24, self-aligning sliding bearing 11, tray 15, roller table 13, support cover 19 and cover 17.

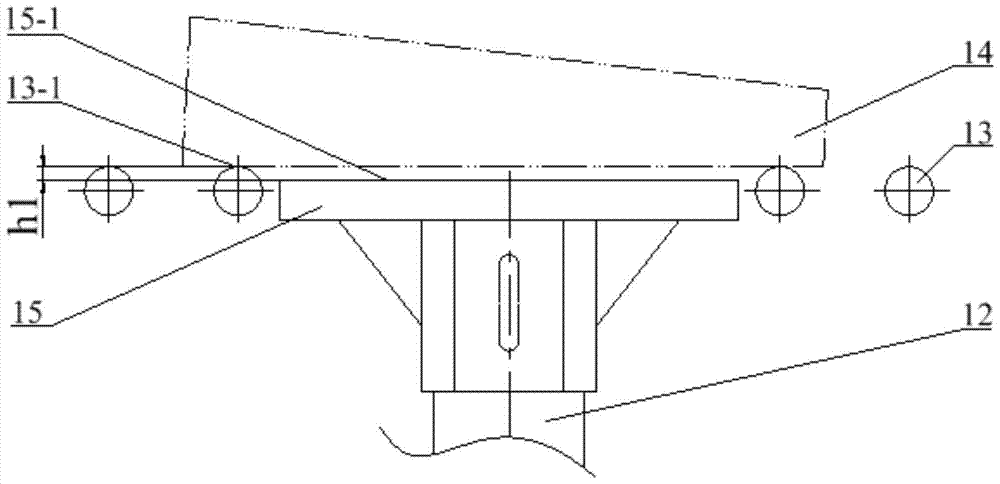

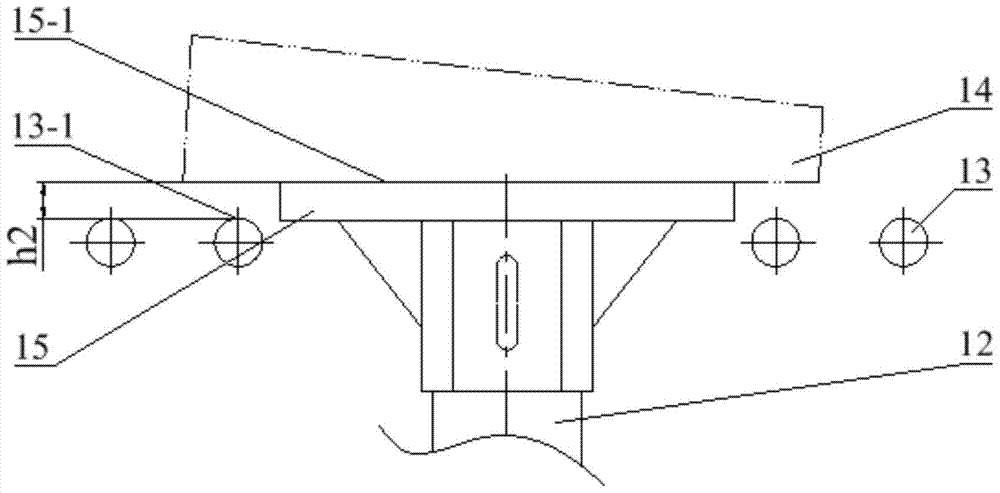

[0030] The orbital body such as Figure 4 , Figure 5 , Figure 6 , Figure 7As shown, it is composed of a cylindrical body 1-1 and a mounting lug 1-2 provided at the lower end of the inner wall of the cylindrical body, the lower end surface 1-1-3 of the cylindrical body is a plane, and the upper end surface is a convex arc surface, The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com