Soil turning mechanism for hard soil

A kind of soil and hard technology, applied in the direction of application, agricultural machinery and implements, shovels, etc., can solve the problems of deep plowing depth, etc., and achieve the effect of improving the quality of soil cultivated land, increasing the area, and expanding the area of loose soil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

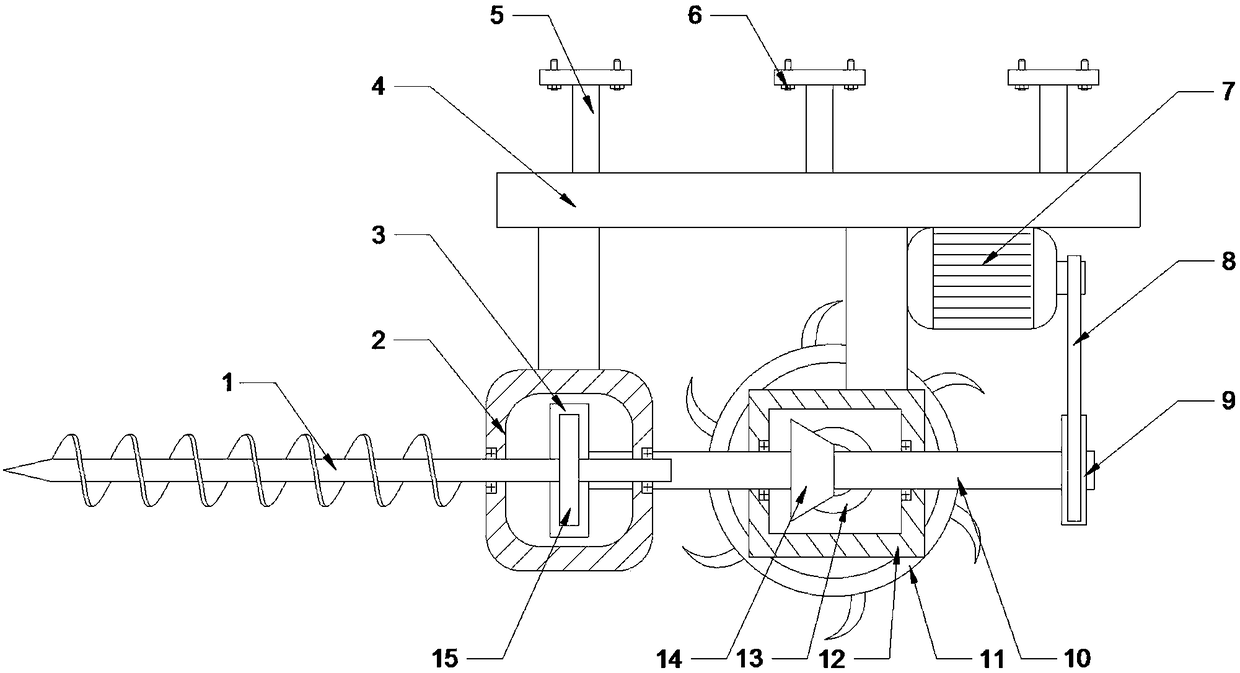

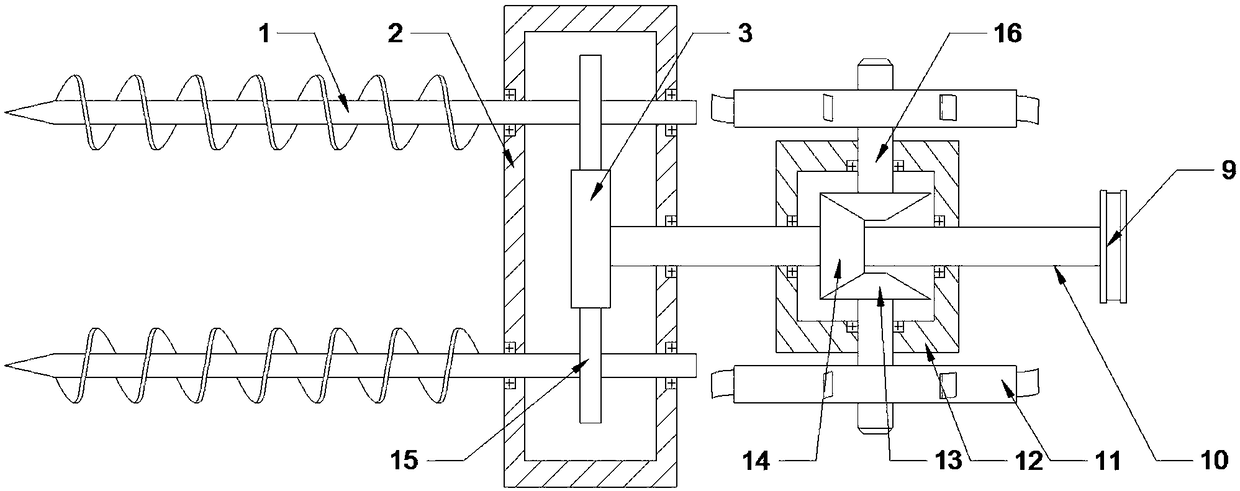

[0027] see Figure 1~2 , a soil-turning mechanism for hard soils, comprising a drive shaft 10, a soil-turning cutter head 11, a soil-turning rotating shaft 16, the drive shaft 10 is installed on the soil drilling positioning box 2 and the soil loosening positioning box 12, and the driving shaft 10 One end stretches into the soil-drilling positioning box 2 and a driving gear 3 is installed at its stretching end; Gear 14, the driving gear 3 meshes with the driven gear 15, the driven gear 15 is installed on the rotating shaft part of the soil loosening drill 1, the soil loosening drill 1 stretches out of the drilling soil positioning box 2, the second bevel gear 14 and the first cone Gear 13 meshes, and the first bevel gear 13 is installed on the soil turning shaft 16, and the soil turning shaft 16 passes outside the loose soil positioning box 12 and is equipped with a soil turning cutter head 11 at its extended end.

[0028] In this example, the driving shaft 10 rotates to driv...

Embodiment 2

[0030] see Figure 1~2 , a soil-turning mechanism for hard soils, comprising a drive shaft 10, a soil-turning cutter head 11, a soil-turning rotating shaft 16, the drive shaft 10 is installed on the soil drilling positioning box 2 and the soil loosening positioning box 12, and the driving shaft 10 One end stretches into the soil-drilling positioning box 2 and a driving gear 3 is installed at its stretching end; Gear 14, the driving gear 3 meshes with the driven gear 15, the driven gear 15 is installed on the rotating shaft part of the soil loosening drill 1, the soil loosening drill 1 stretches out of the drilling soil positioning box 2, the second bevel gear 14 and the first cone Gear 13 meshes, and the first bevel gear 13 is installed on the soil turning shaft 16, and the soil turning shaft 16 passes outside the loose soil positioning box 12 and is equipped with a soil turning cutter head 11 at its extended end.

[0031] There are at least two driven gears 15 meshed with th...

Embodiment 3

[0034] see Figure 1~2 , a soil-turning mechanism for hard soils, comprising a drive shaft 10, a soil-turning cutter head 11, a soil-turning rotating shaft 16, the drive shaft 10 is installed on the soil drilling positioning box 2 and the soil loosening positioning box 12, and the driving shaft 10 One end stretches into the soil-drilling positioning box 2 and a driving gear 3 is installed at its stretching end; Gear 14, the driving gear 3 meshes with the driven gear 15, the driven gear 15 is installed on the rotating shaft part of the soil loosening drill 1, the soil loosening drill 1 stretches out of the drilling soil positioning box 2, the second bevel gear 14 and the first cone Gear 13 meshes, and the first bevel gear 13 is installed on the soil turning shaft 16, and the soil turning shaft 16 passes outside the loose soil positioning box 12 and is equipped with a soil turning cutter head 11 at its extended end.

[0035] There are two first bevel gears 13 meshing with the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com