Pneumatic front chuck

A front-mounted, pneumatic technology, applied in the direction of measuring devices, electrical components, instruments, etc., can solve problems such as affecting cutting, slow response, and insufficient clamping, so as to improve the smoothness of movement, reduce manufacturing costs, and ensure clamping. The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to better understand the above technical solutions, the above technical solutions will be described in detail below with reference to the accompanying drawings and specific embodiments.

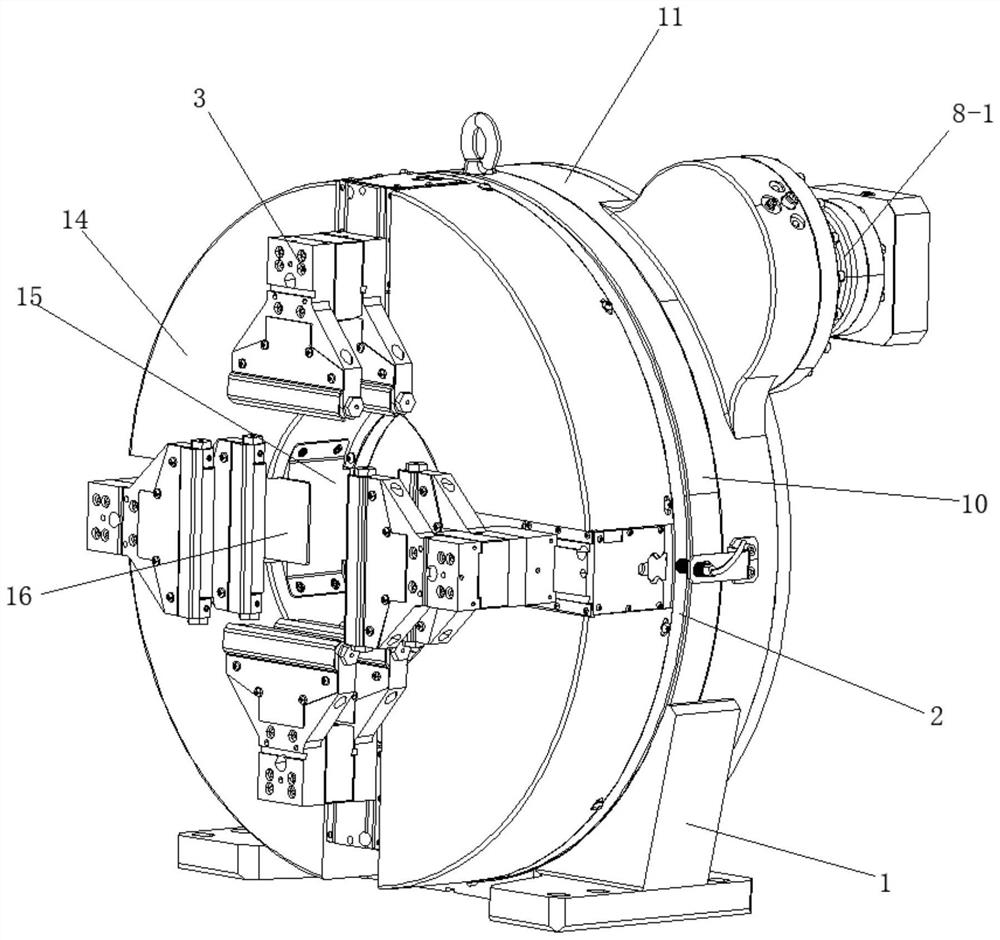

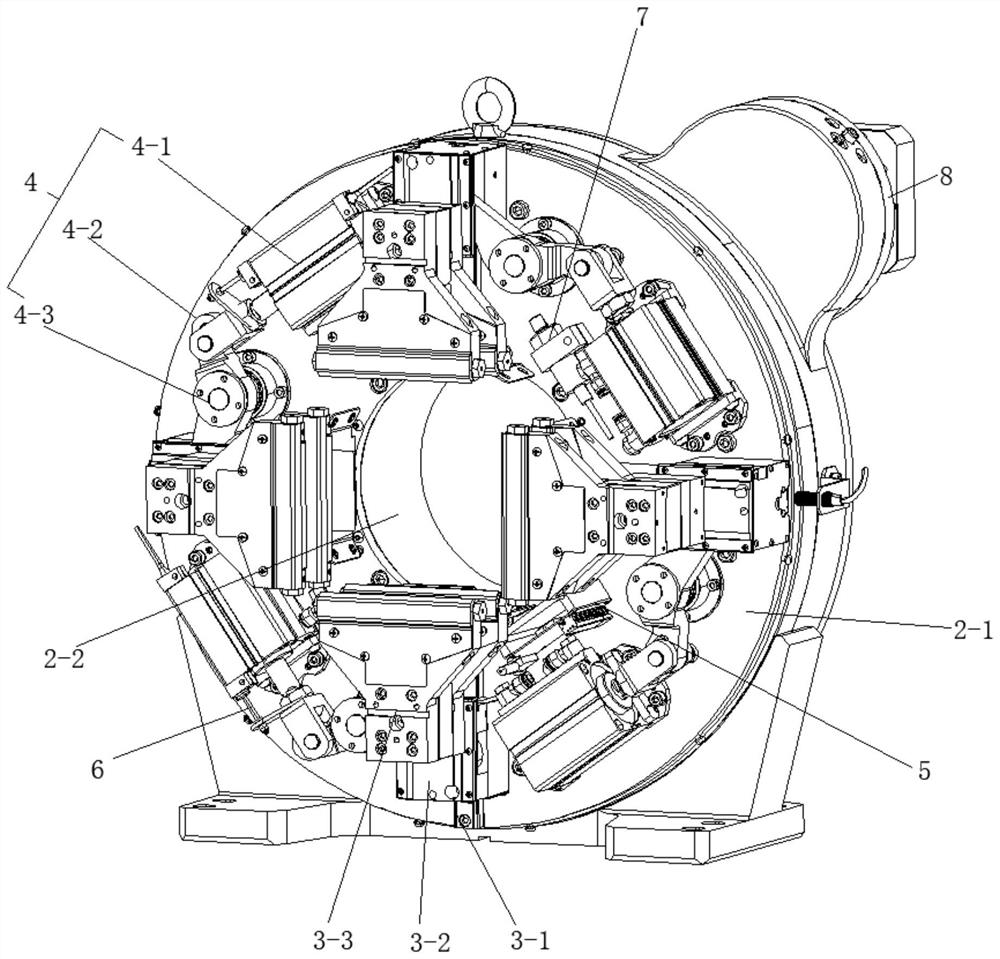

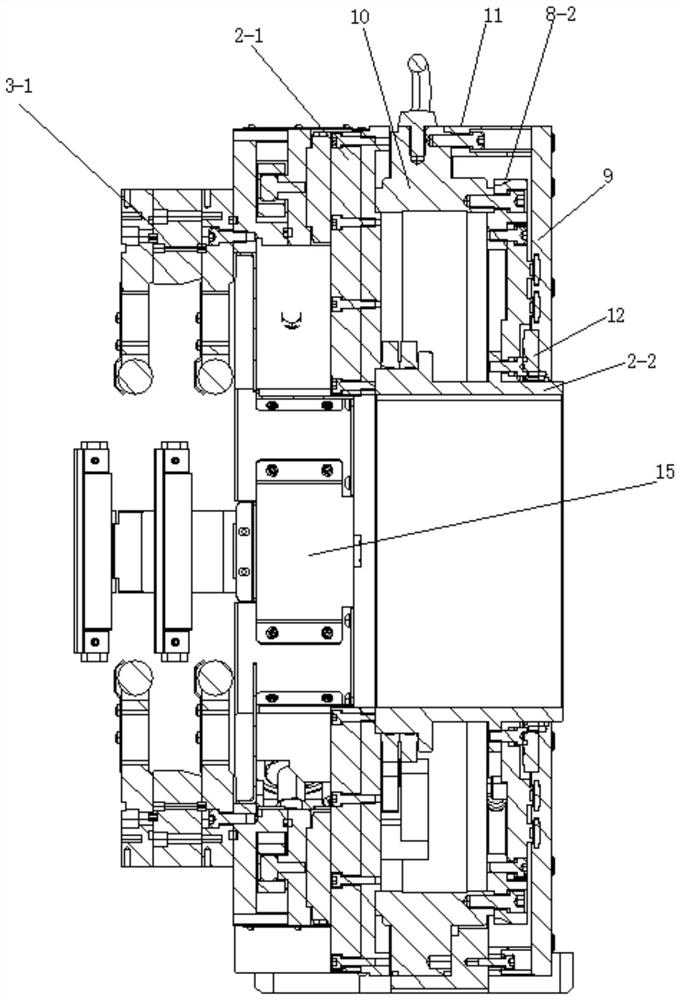

[0028] like Figure 1 to Figure 4 The shown intelligent pneumatic chuck includes a base 1 and a rotating body 2 that is rotatably mounted on the base 1 and rotates around itself. The front end of the rotating body 2 is provided with a clamping assembly 3, and a pneumatic clamping driving device 4 is provided inside. , the circuit board 5, and the displacement detection device 6 and the air pressure detection device 7 connected with the pneumatic clamping drive device 4, wherein the displacement detection device 6 and the air pressure detection device 7 are both electrically connected with the circuit board 5, and the circuit board is connected to the external system, which can The pneumatic clamping drive device 4 of the chuck is monitored in real time to ensure the clamping a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com