Armored forming device and equipment, and cable armoring technology

A molding device and cable technology, which is applied in the field of cable armoring, can solve the problems of insufficient armor layer, affecting the appearance, and scratches on the surface of the armor layer, and achieve the effects of saving metal strips, compact structure, and increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] In order to fully understand the technical content of the present invention, the technical solutions of the present invention will be further introduced and illustrated below in conjunction with specific examples, but not limited thereto.

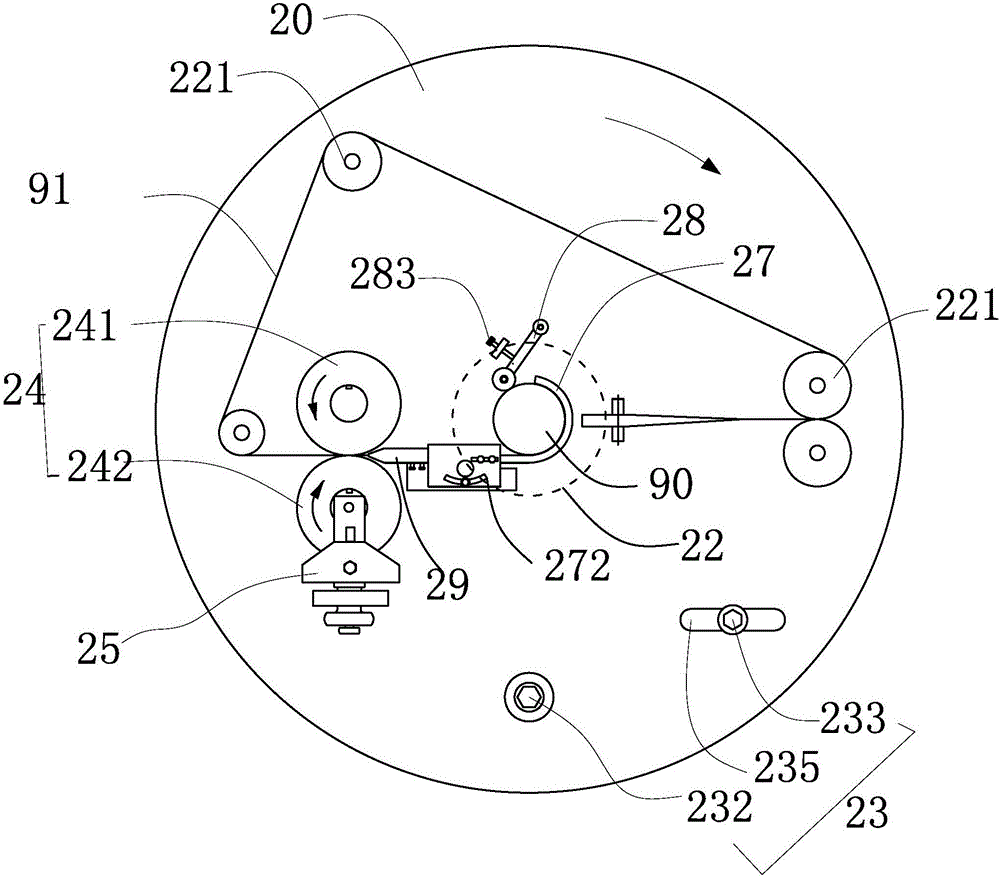

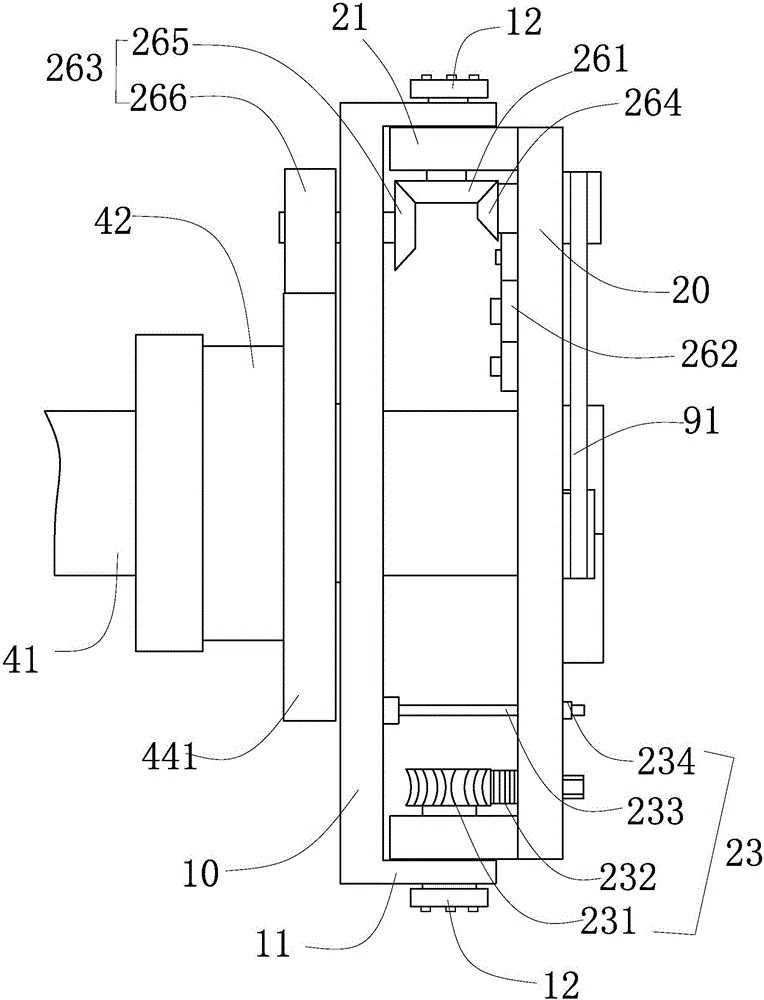

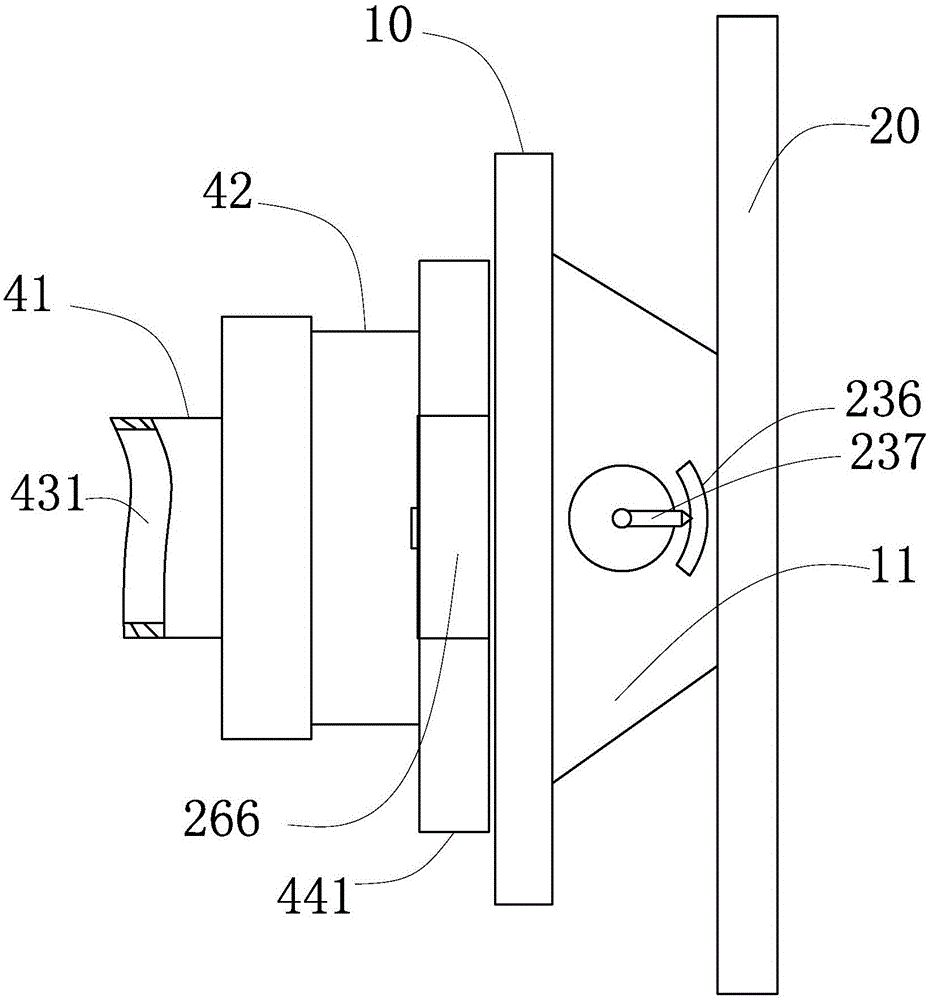

[0044] Figure 1 to Figure 3 As shown, an armor forming device 30 includes a rotating base 10, and fixed shafts 12 are fixedly connected to both sides of the rotating base 10, and the fixed shafts 12 are fixed on the fixed plates 11 arranged symmetrically on both sides of the rotating base 10 by several bolts. . The turntable 20 that is rotatably connected to the fixed shaft 12 on both sides, the two sides of the turntable 20 are symmetrically provided with connecting plates 21, the outer side of the connecting plate 21 is nested in the inner side of the fixed plate 11, and the through hole provided on the connecting plate 21 rotates with the fixed shaft 12 connect. The turntable 20 is provided with an angle adjustment mechanism 23...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com