Gap-adjustable magnetic force testing device

A technology of a testing device and a gap adjustment mechanism, applied in the direction of magnetic performance measurement, etc., can solve the problems of large adsorption force calculation error, small application range of magnetic force testing device, complex calculation method, etc., and achieve accurate measurement, fast test results, and flexible structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

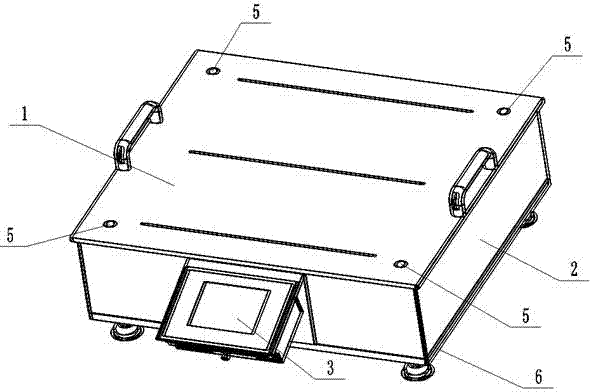

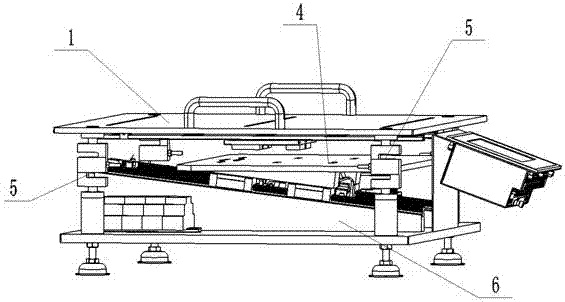

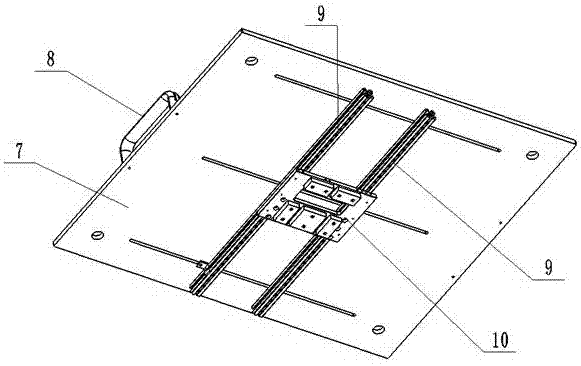

[0041] A gap adjustable magnetic test device, comprising a housing 2, a supporting mechanism 6, a tension pressure sensor 5, a magnet mounting system 1, a gap adjustment mechanism, a magnetic conductive plate 4, and a measurement and control system; the supporting mechanism 6 is placed horizontally, and the supporting mechanism There are multiple tension and pressure sensors 5 fixedly connected to 6, the magnet mounting system 1 is placed horizontally on the multiple tension and pressure sensors 5 probes, and the magnet mounting system 1 is below the magnetic conductive plate 4, and the magnetic conductive plate 4 is fixedly connected On the gap adjusting mechanism, the magnetic conductive plate 4 can be translated along the guide rail 16 of the gap adjusting mechanism to adjust the adsorption gap between the magnet mounting system 1 and the magnetic conductive plate 4. The gap adjusting mechanism is fixedly connected to the supporting mechanism 6, and the supporting mechanism 6 ...

Embodiment 2

[0044] A gap adjustable magnetic test device, comprising a housing 2, a supporting mechanism 6, a tension and pressure sensor 5, a magnet mounting system 1, a gap adjustment mechanism, a magnetic conductive plate 4, and a measurement and control system; the supporting mechanism 6 is placed horizontally, the A plurality of tension and pressure sensors 5 are fixedly connected to the supporting mechanism 6, and the magnet mounting system 1 is placed horizontally on the probes of the plurality of tension and pressure sensors 5. Below the magnet mounting system 1 is a magnetic conductive plate 4, and the magnetic conductive plate 4 It is fixedly connected to the gap adjustment mechanism, and the magnetic conductive plate 4 can be translated along the guide rail 16 of the gap adjusting mechanism to adjust the adsorption gap between the magnet mounting system 1 and the magnetic conductive plate 4. The gap adjusting mechanism is fixedly connected to the supporting mechanism 6 to support ...

Embodiment 3

[0065] On the basis of Embodiments 1 and 2, a gap adjustable magnetic test device includes a supporting mechanism, a tension and pressure sensor, a magnet mounting system, a gap adjustment mechanism, a magnetic conductive plate, and a measurement and control system. Such as figure 1 As shown, the device is placed horizontally through the supporting mechanism 6, and the magnet mounting system 1 is horizontally supported on the measuring heads of multiple tension and pressure sensors 5. The operator controls the device through the touch screen 3, sets the suction gap, and quickly reads it through the touch screen 3. Take the test result.

[0066] Such as figure 2 As shown, the support mechanism 6 is placed horizontally, a plurality of tension and pressure sensors 5 are fixedly connected to the mounting post 13 of the support mechanism 6, the height of the plurality of tension and pressure sensors 5 is the same, and the magnet mounting system 1 is horizontally supported on the plura...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com